Pixel structure and display panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0069]FIG. 3 is a schematic top view illustrating a pixel electrode in a pixel structure according to the disclosure. FIG. 4 is a schematic top view illustrating a passivation layer below the pixel electrode depicted in FIG. 3. FIG. 5 is a schematic view illustrating that the pixel electrode depicted in FIG. 3 and the passivation layer depicted in FIG. 4 are overlapped. With reference to FIG. 3, the pixel electrode 120 has at least one block-shaped electrode (i.e., at least one plate electrode) 122 and a plurality of first branch electrodes 124. Particularly, the block-shaped electrode 122 is an electrode region in the pixel electrode 120 and is not patterned; that is, the block-shaped electrode 122 does not have any opening, hole, slit, groove, and gap. By contrast, the first branch electrodes 124 are electrode regions in the pixel electrode 120 and are patterned. The pixel electrode 120 may further include a main electrode (i.e., a main-truck electrode) 126. The first branch elect...

second embodiment

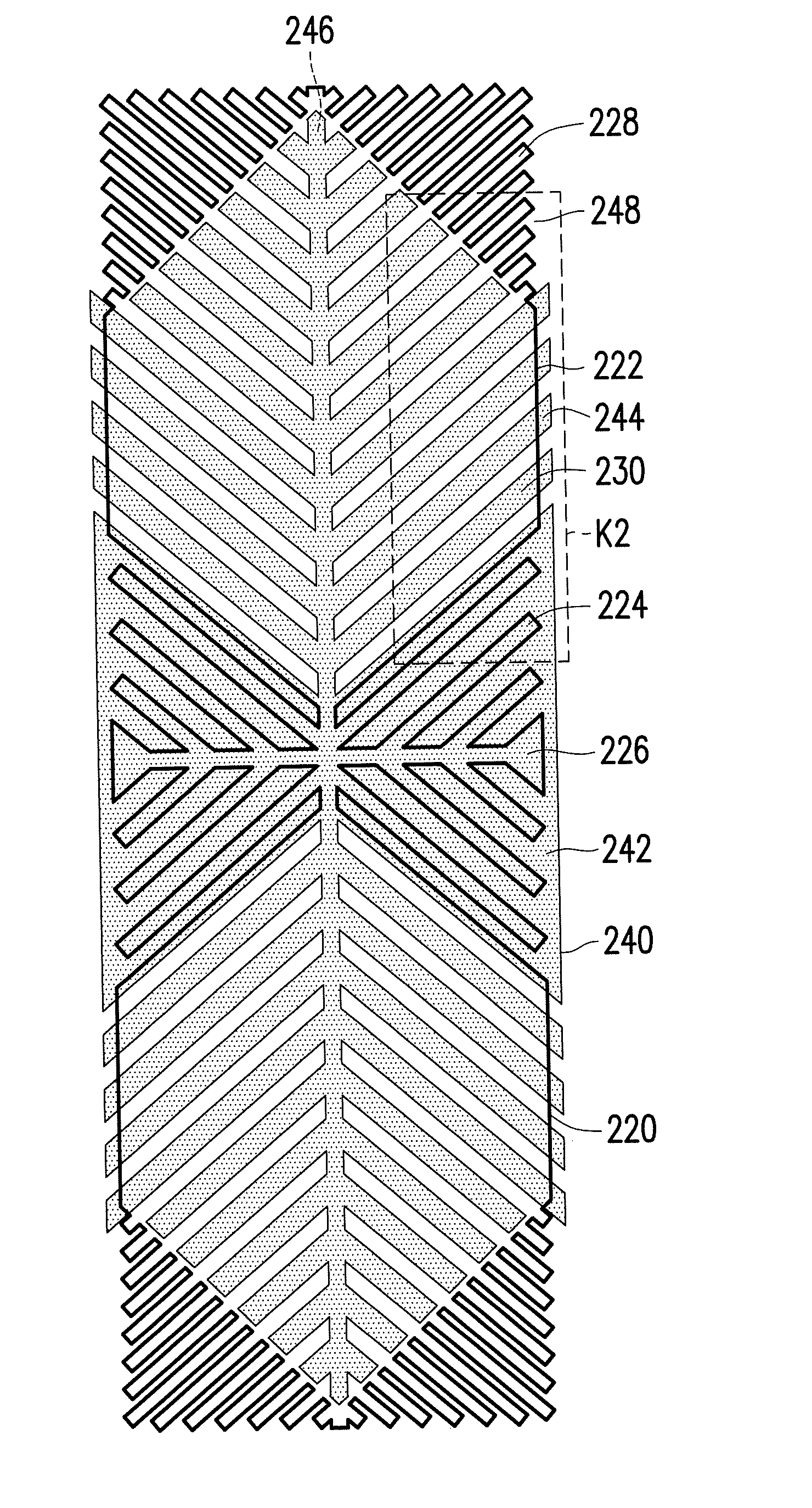

[0077]FIG. 9 is a schematic top view illustrating a pixel electrode in a pixel structure according to the disclosure. FIG. 10 is a schematic top view illustrating a passivation layer below the pixel electrode depicted in FIG. 9. FIG. 11 is a schematic view illustrating that the pixel electrode depicted in FIG. 9 and the passivation layer depicted in FIG. 10 are overlapped. As shown in FIG. 9, the pixel electrode 220 has at least one block-shaped electrode (i.e., at least one plate electrode) 222, a plurality of first branch electrodes 224, a main electrode (i.e., a main-truck electrode) 226, and a plurality of outer branch electrodes 228. Particularly, the block-shaped electrode 222 is an electrode region in the pixel electrode 220 and is not patterned; that is, the block-shaped electrode 222 does not have any opening, hole, slit, groove, and gap. By contrast, the first branch electrodes 224, the main electrode 226, and the outer branch electrodes 228 are electrode regions in the pi...

third embodiment

[0083]FIG. 13 is a schematic top view illustrating a pixel electrode in a pixel structure according to the disclosure. FIG. 14 is a schematic top view illustrating a passivation layer below the pixel electrode depicted in FIG. 13. FIG. 15 is a schematic view illustrating that the pixel electrode depicted in FIG. 13 and the passivation layer depicted in FIG. 14 are overlapped. As shown in FIG. 13, the pixel electrode 320 has at least one block-shaped electrode (i.e., at least one plate electrode) 322, a plurality of first branch electrodes 324, a first main electrode (i.e., a first main-truck electrode) 326, and a second main electrode (i.e., a second main-truck electrode) 328. Particularly, the block-shaped electrode 322 is an electrode region in the pixel electrode 320 and is not patterned; that is, the block-shaped electrode 322 does not have any opening, hole, slit, groove, and gap. By contrast, the first branch electrodes 324 are electrode regions in the pixel electrode 320 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com