Snowmaking automation system and modules

a technology of automatic snowmaking and modules, which is applied in the direction of recreational ice production, domestic applications, lighting and heating apparatus, etc. it can solve the problems of affecting the safety of ski resort employees, and affecting the safety of ski resort personnel,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

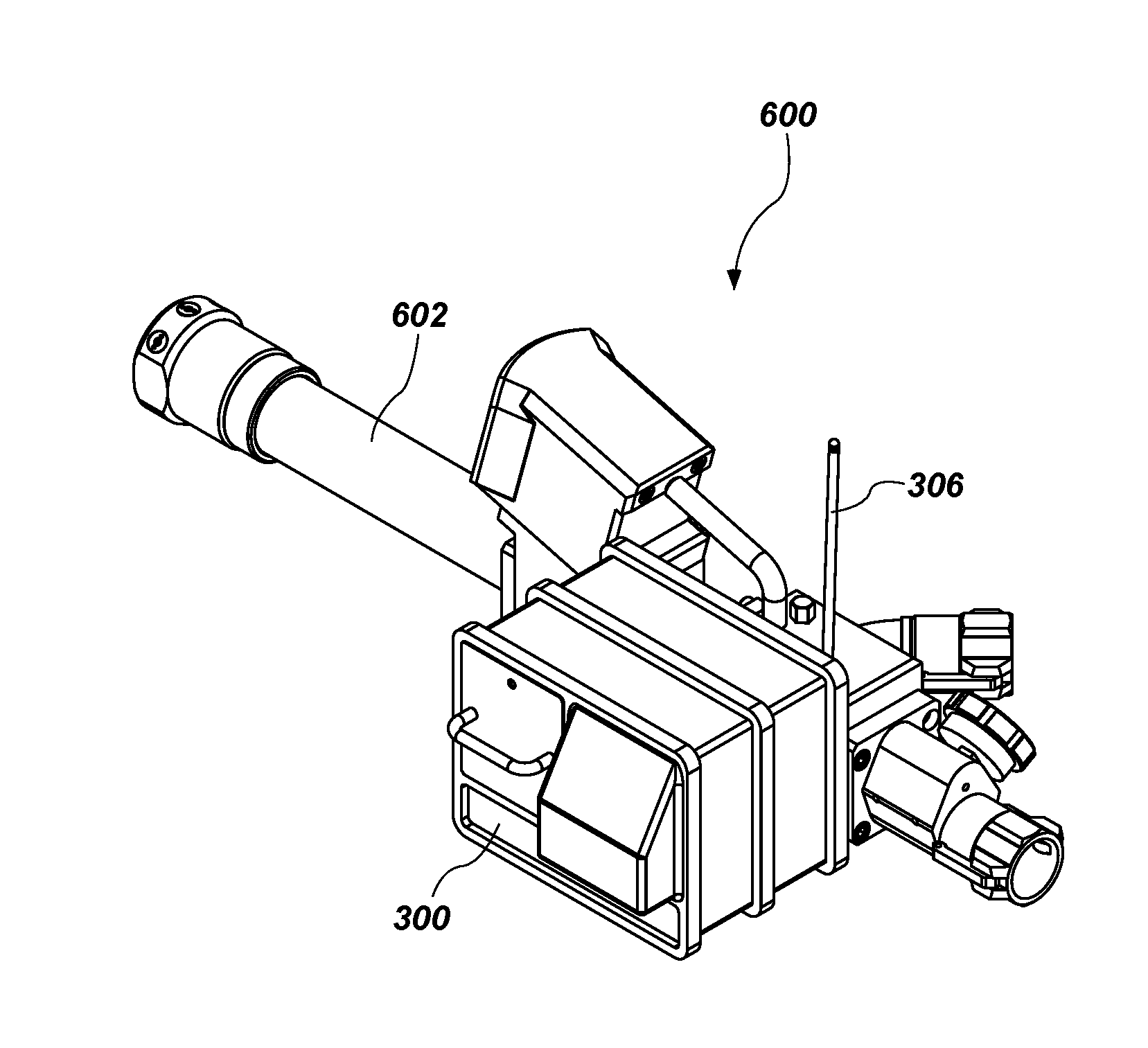

Image

Examples

Embodiment Construction

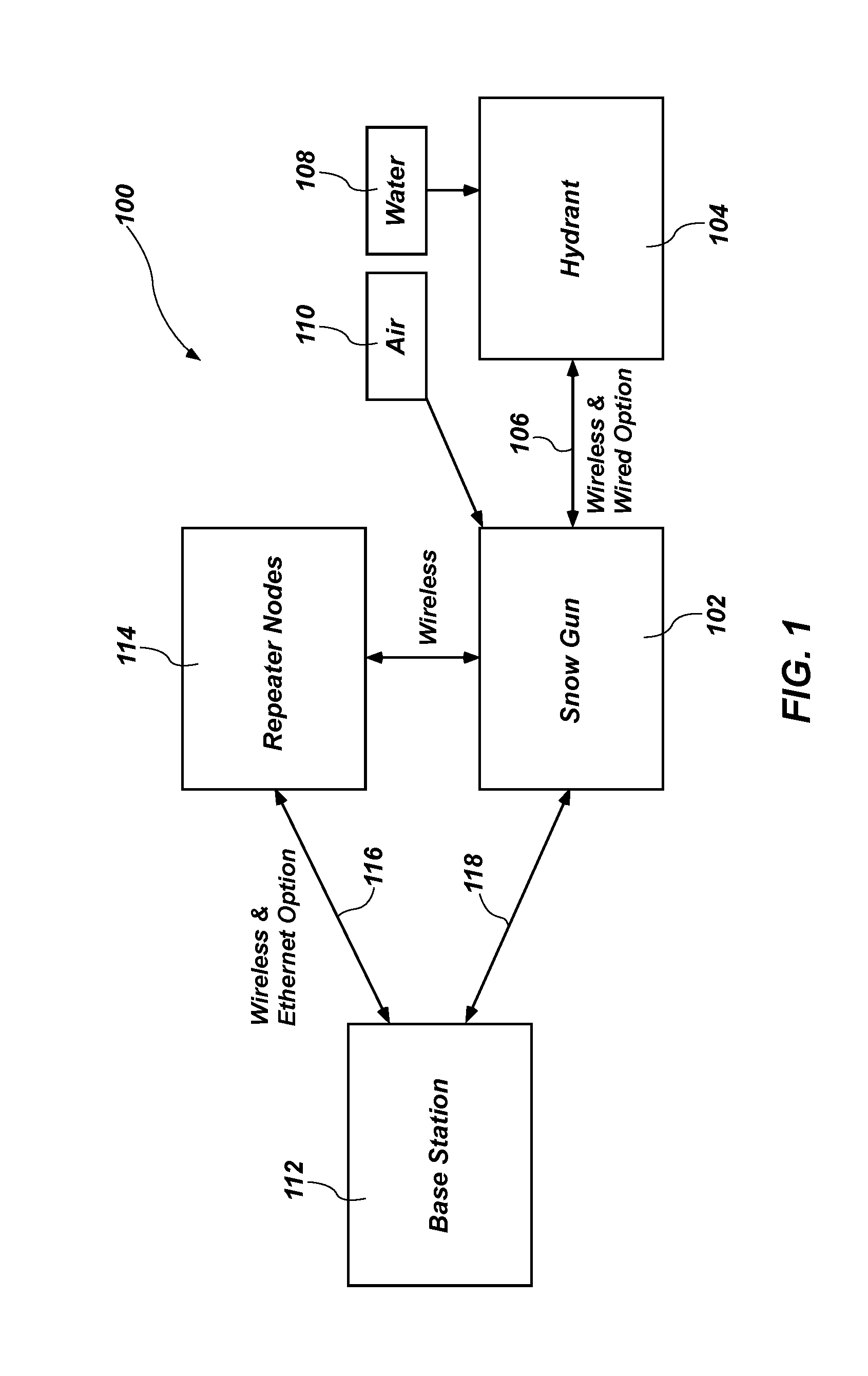

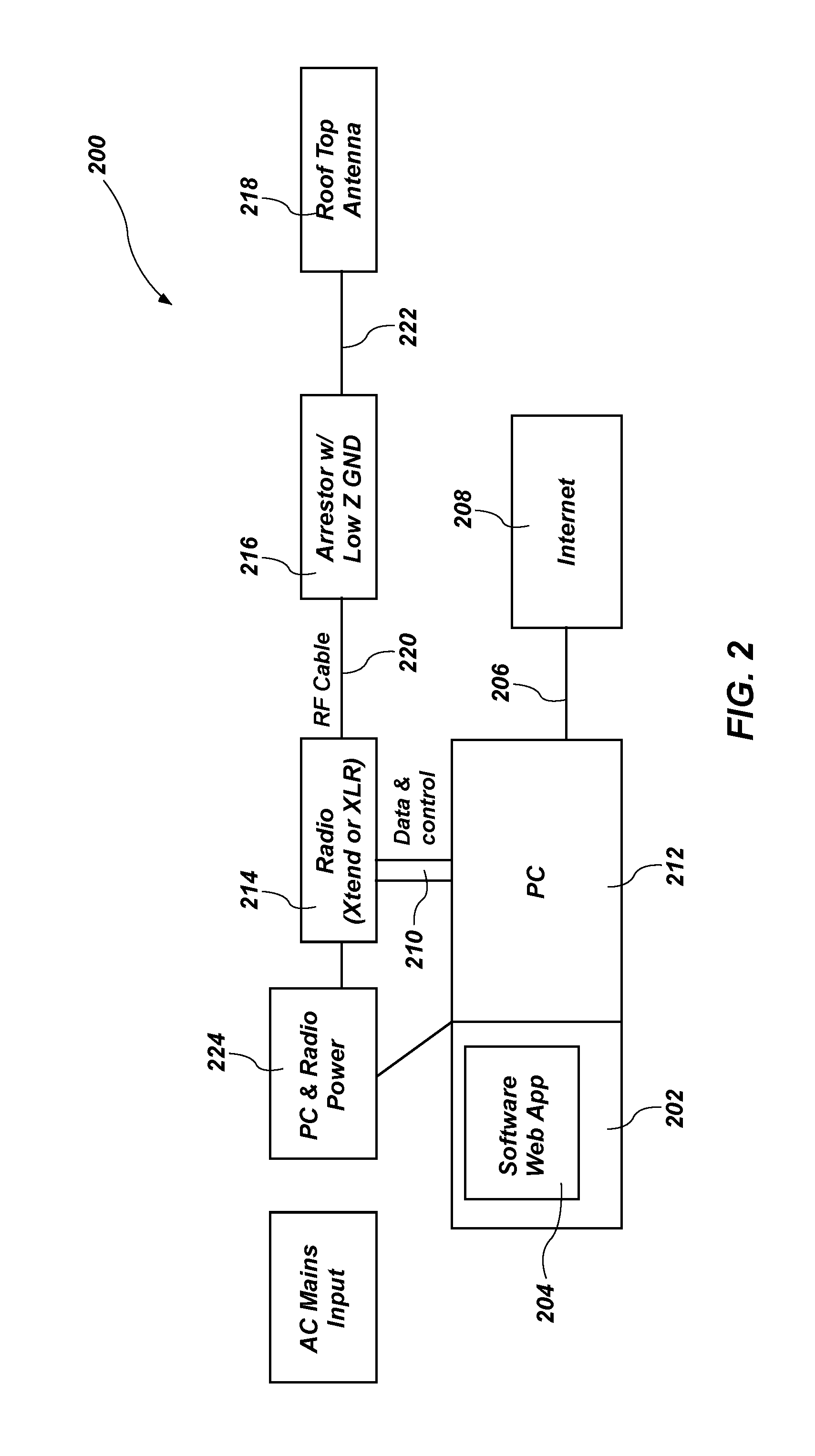

[0035]Embodiments of the invention include a snowmaking automation system for use with snowmaking guns and hydrants. Embodiments of the snowmaking automation system described herein may be battery powered, and thus do not require fixed electrical infrastructure, but are designed to use such infrastructure if present on the mountain. The battery life is designed to operate the actuator for 150-200 hours before recharging according to embodiments of a snowmaking automation system of the present invention disclosed herein. This range of time is typically required to complete a batch of snowmaking on a given run at a resort. Some embodiments of the snowmaking automation system are also wireless, and thus, do not require hard-wired communications between base stations and remotely controlled snowmaking guns and hydrants. Another advantageous feature is the anticipated lower cost of operation of the various embodiments of a snowmaking automation systems of the present invention.

[0036]Anot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com