Kicking shoe attachment for propelling kick scooters and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

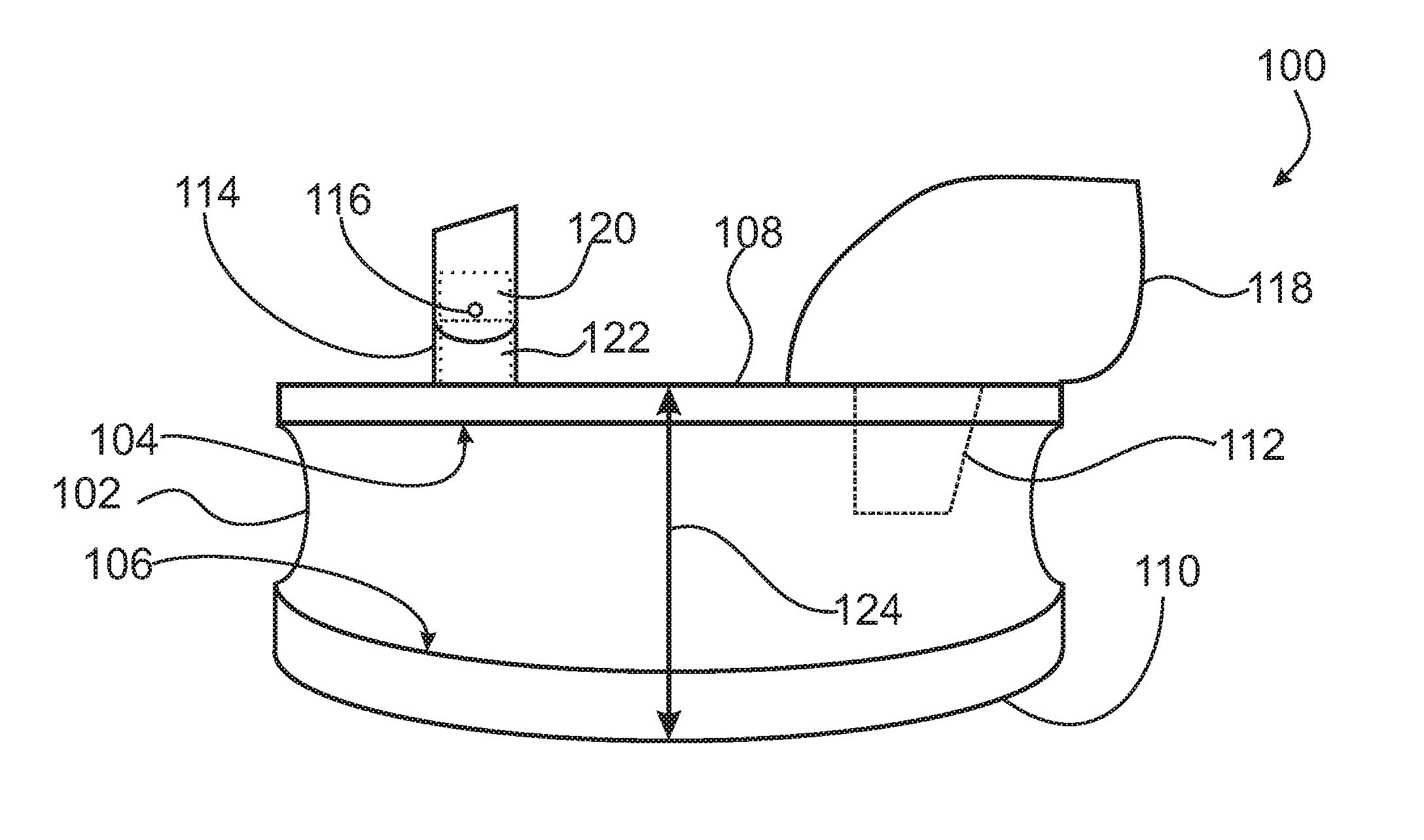

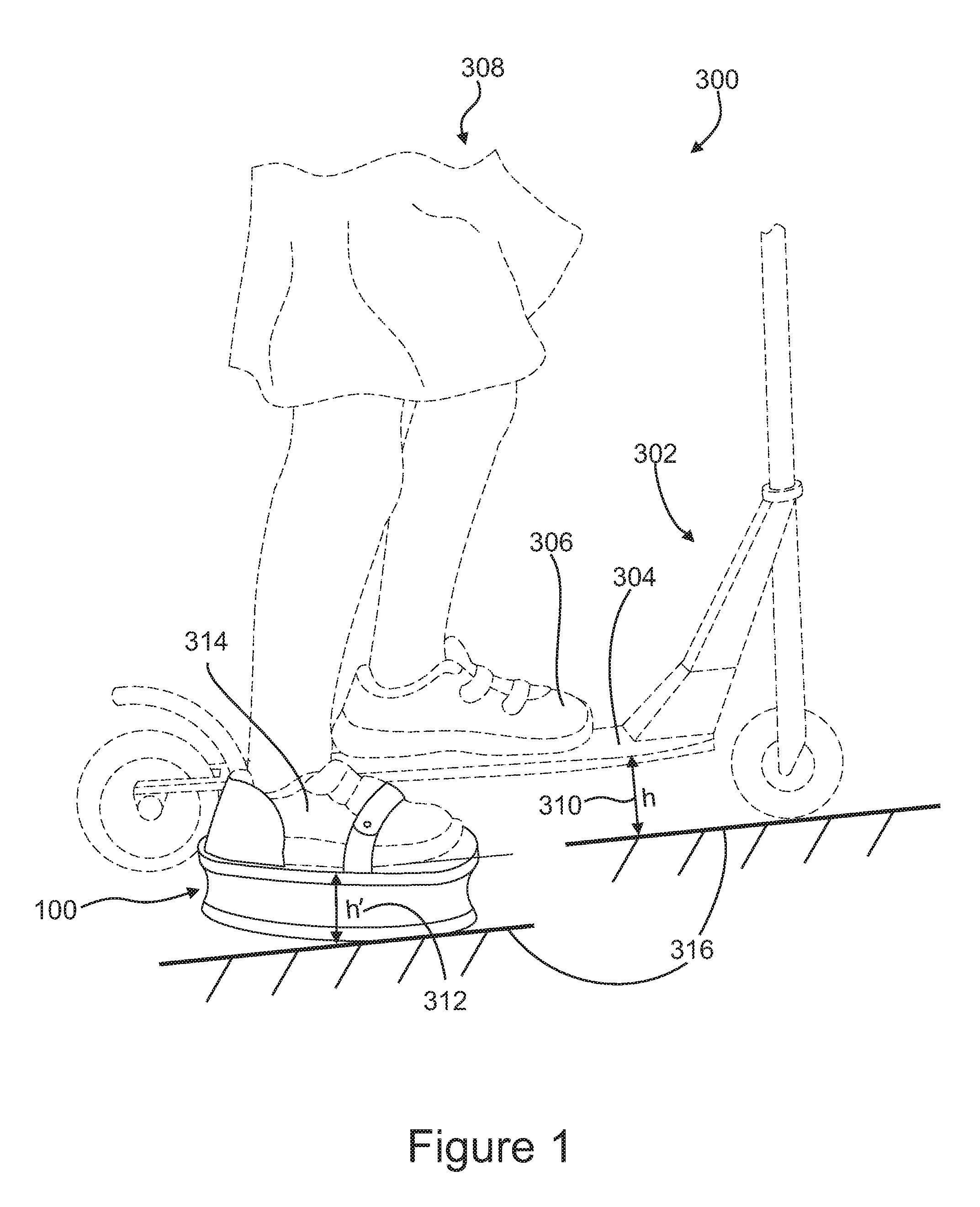

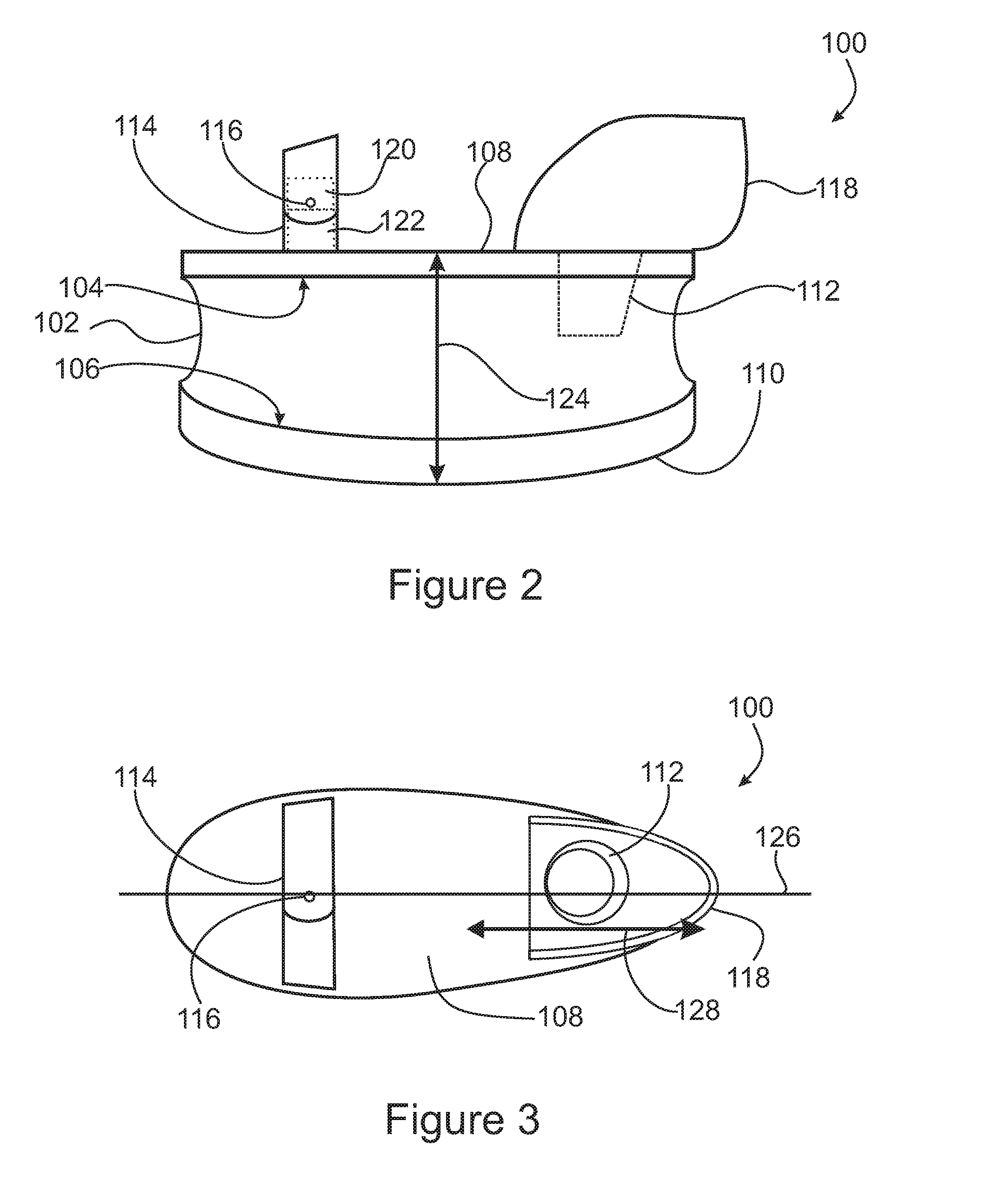

[0042]Referring now also to FIG. 2, there is shown a side elevational, schematic view of first embodiment of a kicking shoe attachment in accordance with the invention, generally at reference number 100.

[0043]A solid main body core 102 has a substantially flat upper surface 104, and a convex lower surface 106. In this embodiment, main body core 102 is formed from a solid piece of sturdy, lightweight material. Such lightweight, sturdy materials include lightweight metals such as aluminum and polymers such as ABS. It will be recognized that numerous other lightweight, sturdy materials may be known to those of skill in the art and, consequently, the invention is not limited by the material examples chosen for purposes of disclosure. Rather, the invention is intended to include any suitable main body core 102 material.

[0044]An upper sole 108 is fastened to the upper surface 104 of main body core 102. Upper sole 108 is typically formed from rubber, either natural or artificial, or from a...

second embodiment

[0056]Referring now also toFIG. 5, there is shown a side elevational, schematic view of the kicking shoe attachment with springs within the elongated main body, generally at reference number 150.

[0057]In the kicking shoe attachment 150 elongated main body core 102 of kicking shoe attachment 100 is split into two portions; and upper body portion 152 and a lower body portion 154. Each of upper body portion 152 and lower body portion 154 is thinner than solid main body core 102.

[0058]Coil springs 156 are interposed between a lower surface of upper body portion 152 and an upper surface of lower body portion 154. Springs 156 are typically coil springs having sufficient stiffness to maintain connective integrity between upper body portion 152 and lower body portion 154 while providing a kicking assist to the rider of a kick scooter.

[0059]While coil springs 156 are shown for purposes of disclosure, it will be recognized by those of skill in the art that springs of other types, for example,...

third embodiment

[0060]Referring now also to FIG. 6, there is shown a side elevational, schematic view of the kicking shoe attachment with resilient material within the body generally at reference number 200.

[0061]In kicking shoe attachment 200, springs 156 (FIG. 5) are replaced by a block of a resilient material 202. Materials such as polyurethanes, latex, or polyether urethanes (EU) elastomeric foam have been found suitable for the application. It will be recognized by those of skill in that art that suitable other material may be available. Consequently, the invention is not considered limited to the materials chosen for purposes of disclosure. It is anticipated that kicking shoe attachment 200 is less expensive to manufacture while still providing the kicking assist benefits of kicking shoe attachment 150. Resilient material 202 may readily be adhesively attached to a lower surface of upper body portion 152 and an upper surface of lower body portion 154.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Wear resistance | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com