Subsea fluid processing system with intermediate re-circulation

a technology of fluid processing system and fluid flow, which is applied in the direction of machines/engines, mechanical equipment, and well accessories, etc., can solve the problems of gas slugs, high gvf of pumps receiving production fluids with high gvf, and damage to pumps. , to achieve the effect of reducing a gas volume fraction (gvf), efficient handling of production fluids, and high gas volume fraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

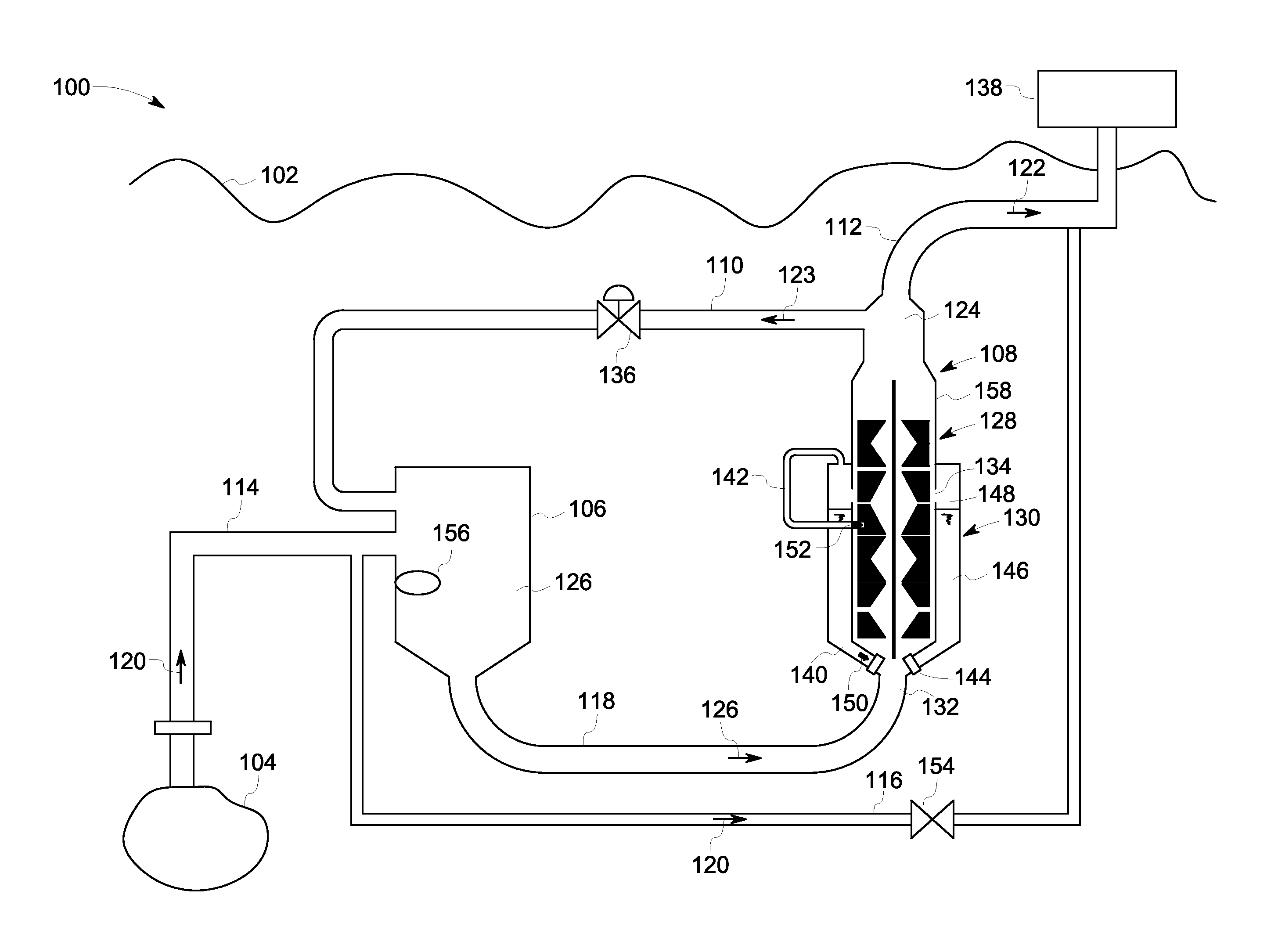

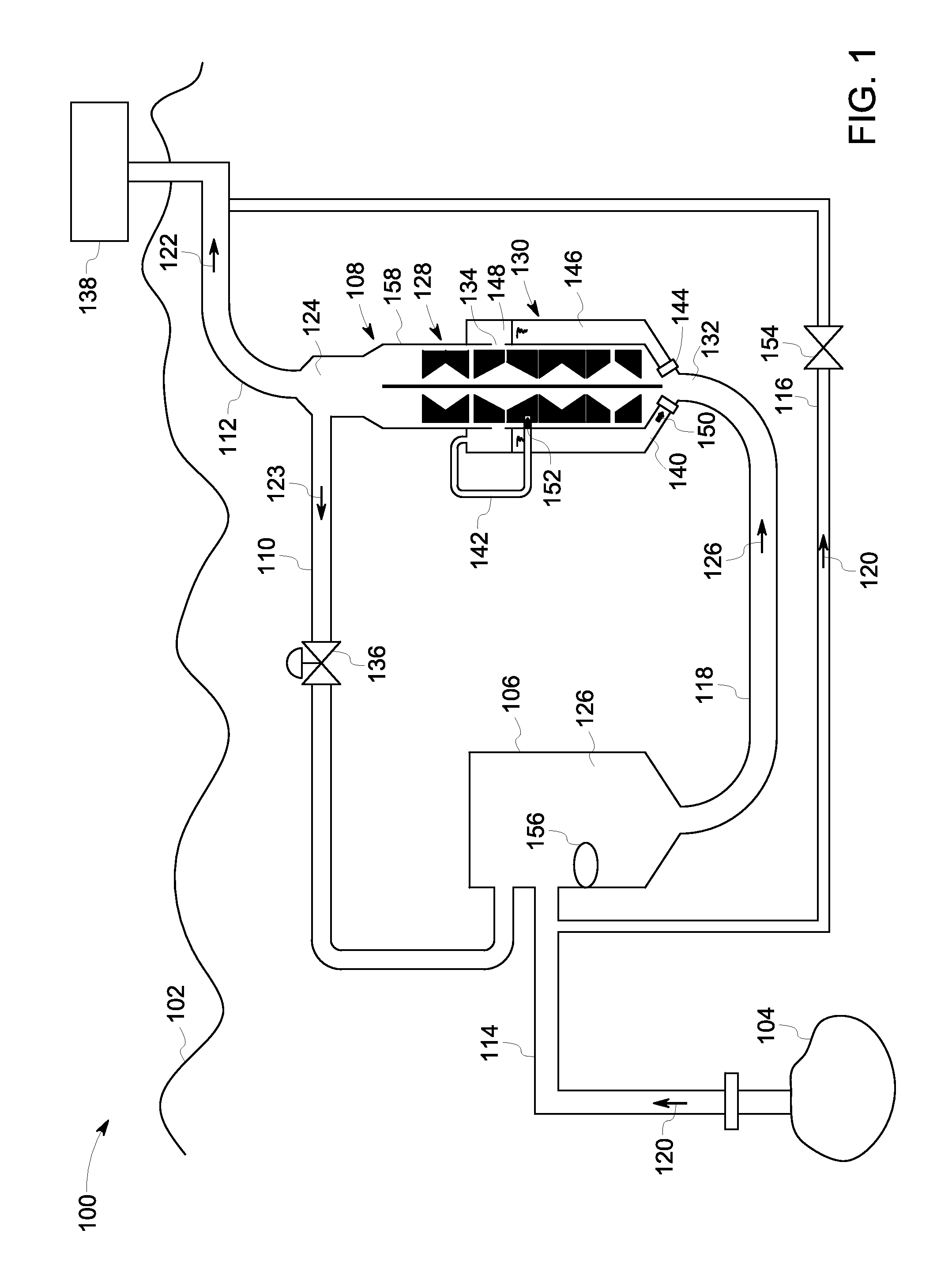

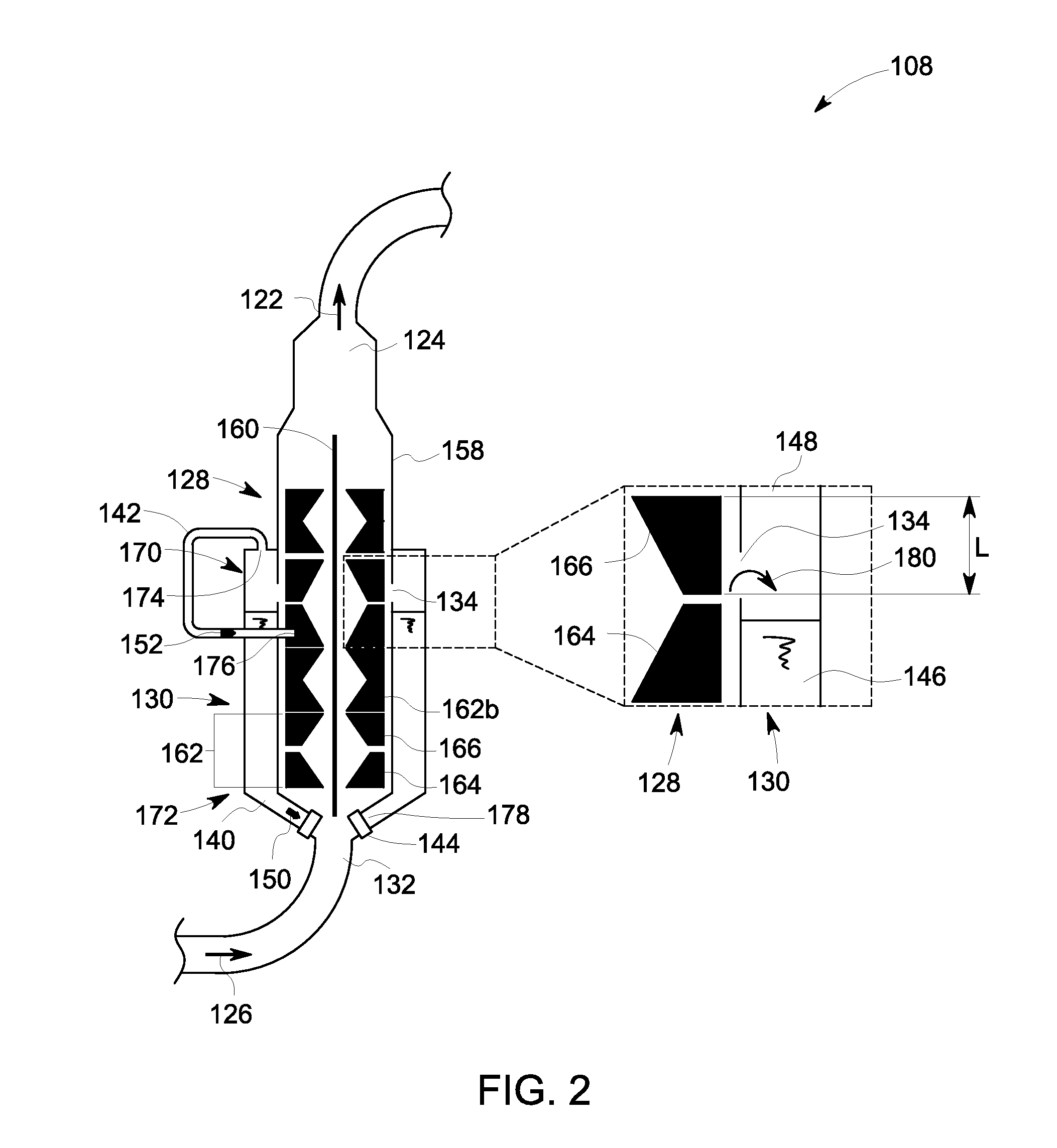

[0027]Embodiments discussed herein disclose new subsea systems for efficiently moving production fluids characterized by high gas volume fraction (GVF) from a hydrocarbon reservoir to a distant fluid storage facility. Specifically, the embodiments disclose an improved fluid processing system for effectively managing the GVF of the production fluids. The fluid processing system of the present invention comprises a pump and a fluid reservoir encompassing a portion of the pump. One or more slots defined in a casing of the pump, are configured to extract a portion of a multiphase fluid flowing in the pump at an intermediate pressure. The one or more slots may be defined in one or more regions of the casing and may have optimal shapes to facilitate extraction of a stagnant portion (flow) of the multiphase fluid without affecting a main flow of the multiphase fluid. A discharge device is coupled to a re-circulation conduit of the fluid reservoir. The discharge device may include one among...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com