Coke slurry fuel composition and method of making the same

a technology of coke slurry and fuel composition, which is applied in the direction of solid fuels, liquid carbonaceous fuels, fuel additives, etc., can solve the problems of taiwan's landfills being exhausted soon, sewage sludge production has serious impact on humans and the environment in which we live, and the world is facing serious energy shortages, so as to increase the shortage of global energy resources and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

The First Embodiment

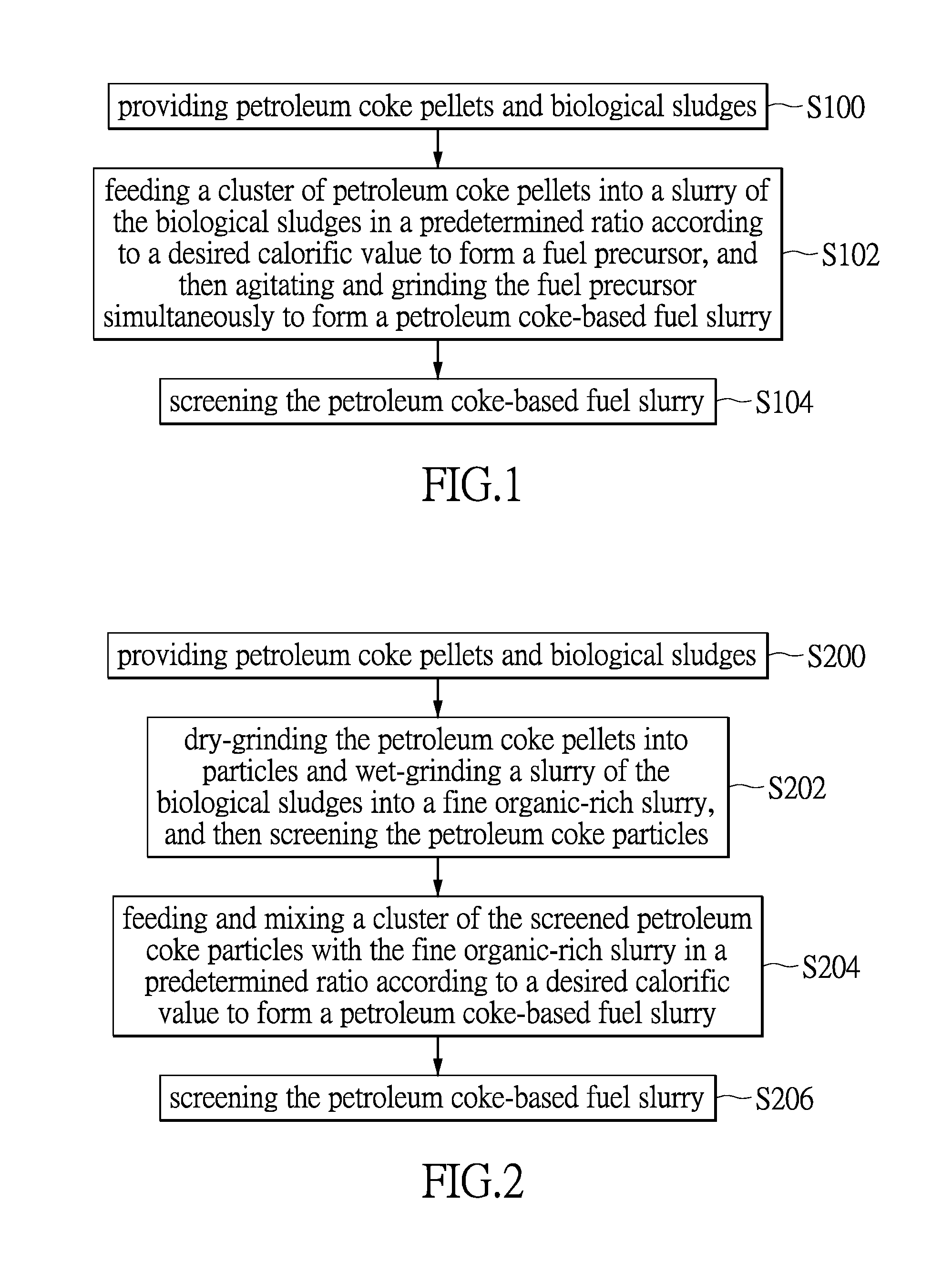

[0025]Please refer to FIG. 1, a method of making coke slurry fuel composition in accordance with a first preferred embodiment is provided. The method comprises the steps of: providing petroleum coke pellets and biological sludges (S100); feeding a cluster of petroleum coke pellets into a slurry of biological sludge in a predetermined ratio according to a desired calorific value to form a fuel precursor, and then agitating and grinding the fuel precursor simultaneously to form a petroleum coke-based fuel slurry (S102); and screening the petroleum coke-based fuel slurry (S104).

[0026]Step S100 is to provide petroleum coke pellets and biological sludges. The petroleum coke pellets can comprise a combination of more than one type of solid coke product, i.e., needle coke, sponge coke, spherical coke and shot coke. The biological sludges can be derived from domestic sewage, industrial sewage, animal sewage, municipal sewage, or the combination thereof. The biological sl...

second embodiment

The Second Embodiment

[0032]Please refer to FIG. 2, a method of making coke slurry fuel composition in accordance with a second preferred embodiment is provided. The method comprises the steps of: providing petroleum coke pellets and biological sludges (S200); dry-grinding the petroleum coke pellets into particles and wet-grinding a slurry of the biological sludges into a fine organic-rich slurry, and then screening the petroleum coke particles (S202); feeding and mixing a cluster of the screened petroleum coke particles with the fine organic-rich slurry in a predetermined ratio according to a desired calorific value to form a petroleum coke-based fuel slurry (S204); and screening the petroleum coke-based fuel slurry (S206).

[0033]Step S200 is to provide petroleum coke pellets and biological sludges. Similarly, the petroleum coke pellets can comprise a combination of more than one type of solid coke product, i.e., needle coke, sponge coke, spherical coke and shot coke, where the shape...

third embodiment

The Third Embodiment

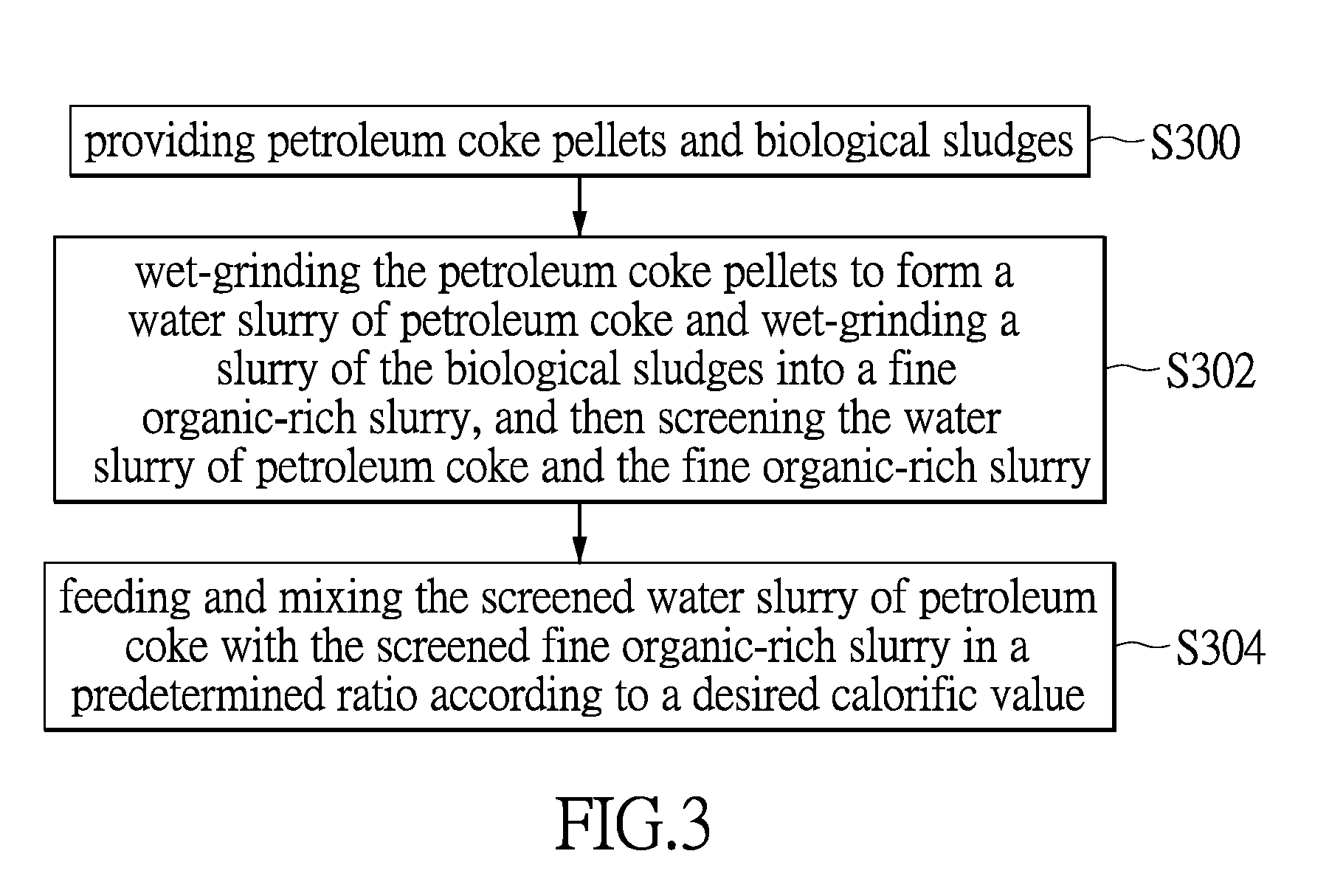

[0039]Please refer to FIG. 3, a method of making coke slurry fuel composition in accordance with a third preferred embodiment is provided. The method comprises the steps of: providing petroleum coke pellets and biological sludges (S300); wet-grinding the petroleum coke pellets to form a water slurry of petroleum coke and wet-grinding a slurry of the biological sludges into a fine organic-rich slurry, and then screening the water slurry of petroleum coke and the fine organic-rich slurry (S302); and feeding and mixing the screened water slurry of petroleum coke with the screened fine organic-rich slurry in a predetermined ratio according to a desired calorific value to form a petroleum coke-based fuel slurry (S304).

[0040]Step S300 is to provide petroleum coke pellets and biological sludges. Similarly, the petroleum coke pellets can comprise a combination of more than one type of solid coke product, i.e., needle coke, sponge coke, spherical coke and shot coke, where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com