Method for preparing a liquid oat base and products prepared by the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0066]β-Glucan content of oat bran base of the invention in relation to amount of xylanase used for its production. The state-of-the-art oat bran based drink described above was incubated at 40° C. for 15 min with different amounts of xylanase. The product was analyzed for β-glucan concentration. The results are shown in Table 1.

TABLE 1β-Glucan content of oat bran base samples treated with differentamounts of xylanase at 40° C. for 15 minXylanase FXU / 100 g OBFβ-glucan(Oat Bran)(% by weight)01.31001.410001.520001.4

example 2

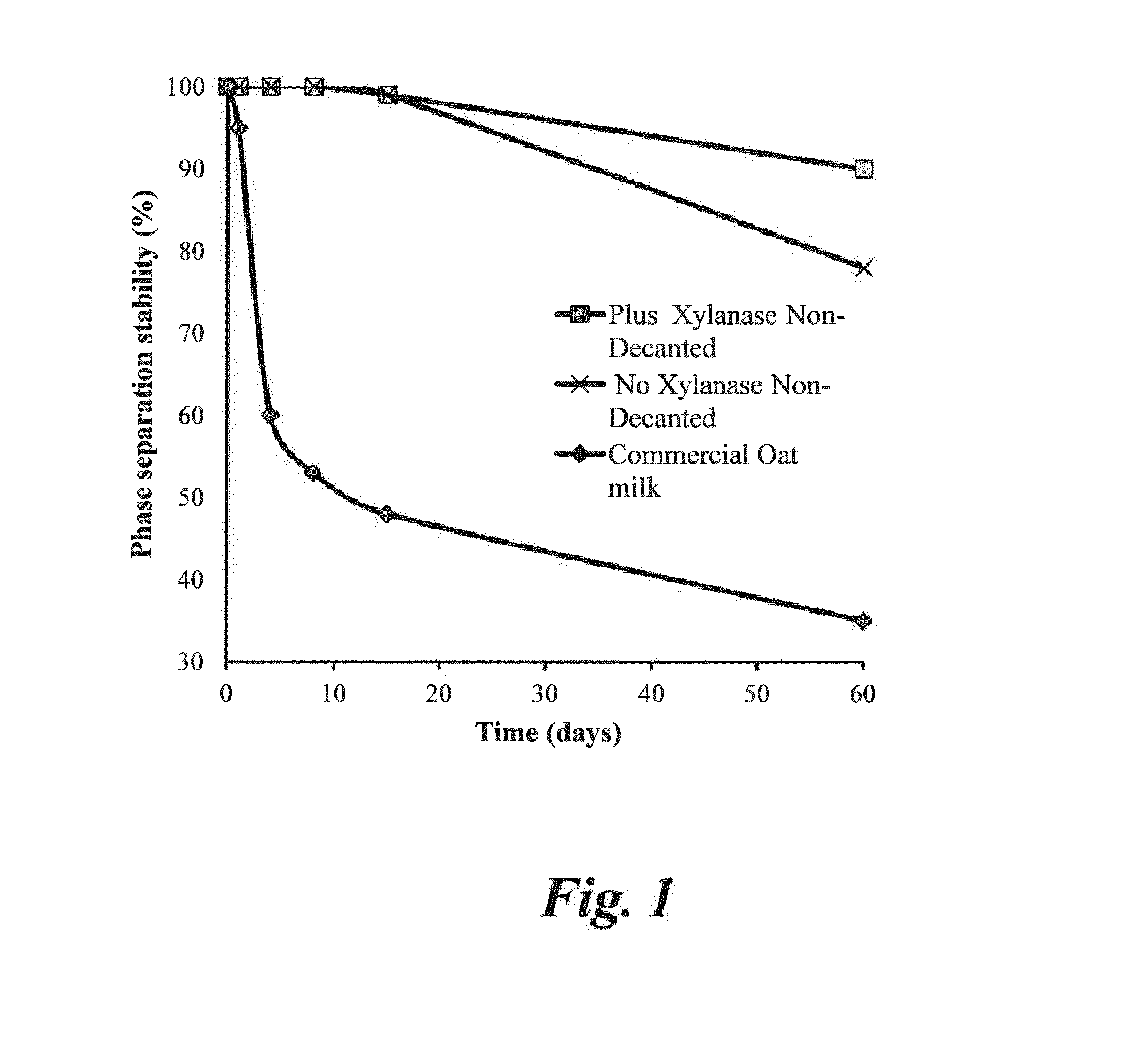

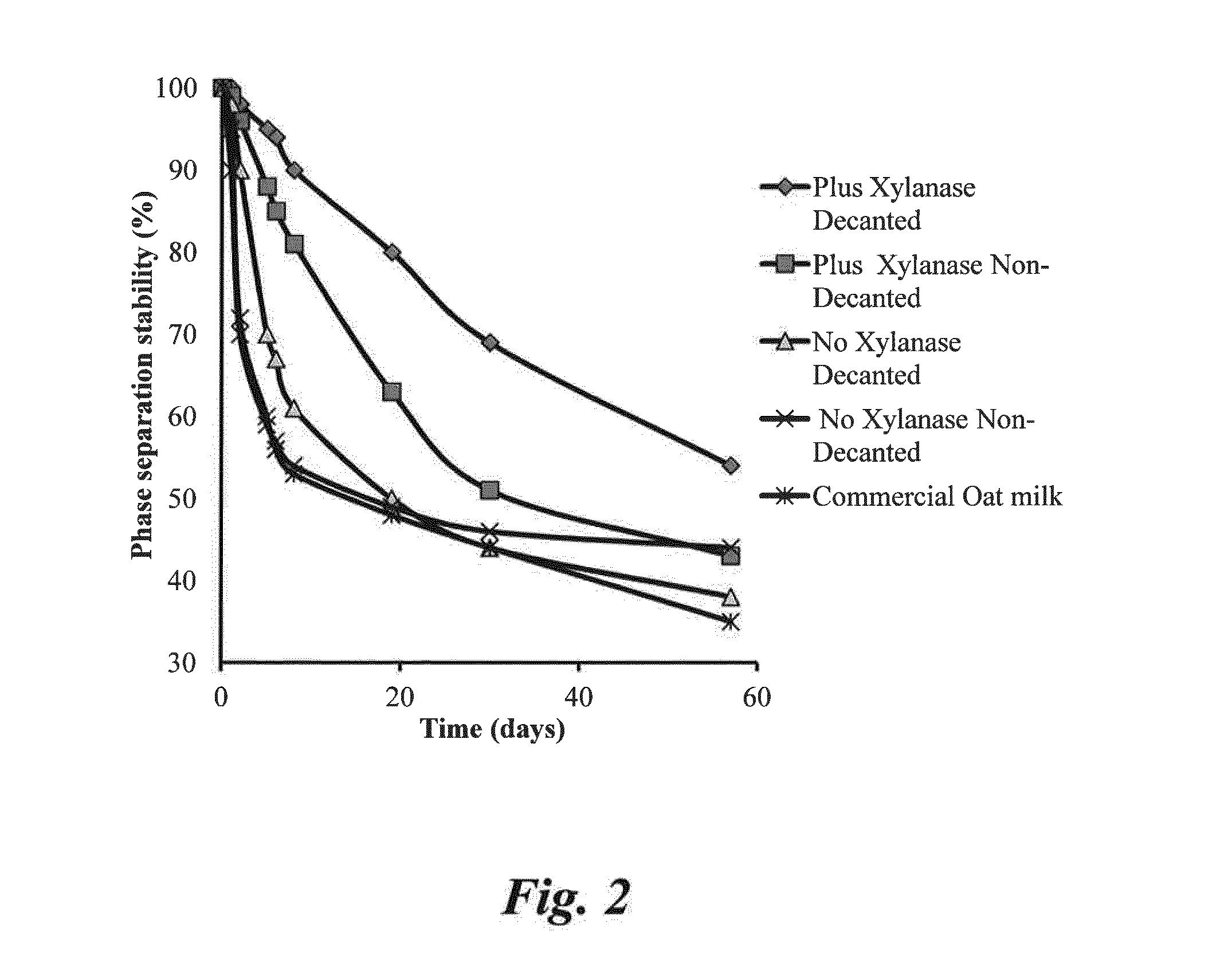

[0067]Physical stability of the improved liquid oat base of the invention. Physical stability was determined by measuring phase separation upon storing in a glass vial a sample of the improved liquid oat base for a given period of time at a selected temperature. During storage an upper clear liquid phase appeared. It increased in height until a stable end point state was reached at which the height of the lower particulate phase remained stable. Physical stability index Iphs at time tts is conveniently expressed as 100× the ratio of upper phase height at ts to upper phase height at end point (storage for indefinite period) at which sedimentation equilibrium has been reached.

[0068]A decreased separation rate is indicative of improved physical stability. Homogenized samples of the aqueous oat base of the invention and the prior art aqueous oat base not treated with xylanase were stored in test tubes at 4° C. Phase separation (upper aqueous phase; lower particulate phase) was measured ...

example 3

[0070]Effect of xylanase concentration on the content of soluble arabinoxylan. Soluble arabinoxylan content was measured after incubation at 40° C. of samples at different xylanase concentrations. The results are shown in Table 4 expressed as xylose equivalents.

TABLE 4Xylose equivalents (XE) in samples treated with differentconcentrations of xylanase (w / v) for 60 minXylanaseXE(FXU / 100 g OBF)(mM)00.381007.4100015.0200014.0

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com