Device for Preheating a Fluid, In Particular Coolant for a Combustion Engine

a technology for preheating fluids and combustion engines, which is applied in the direction of fluid heaters, electric heating, electrical apparatus, etc., can solve the problems of difficult placement on the circuit, low yield of heaters, and unreliable heaters in time, so as to reduce the loss in the atmosphere, increase heat exchange efficiency, and optimize thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

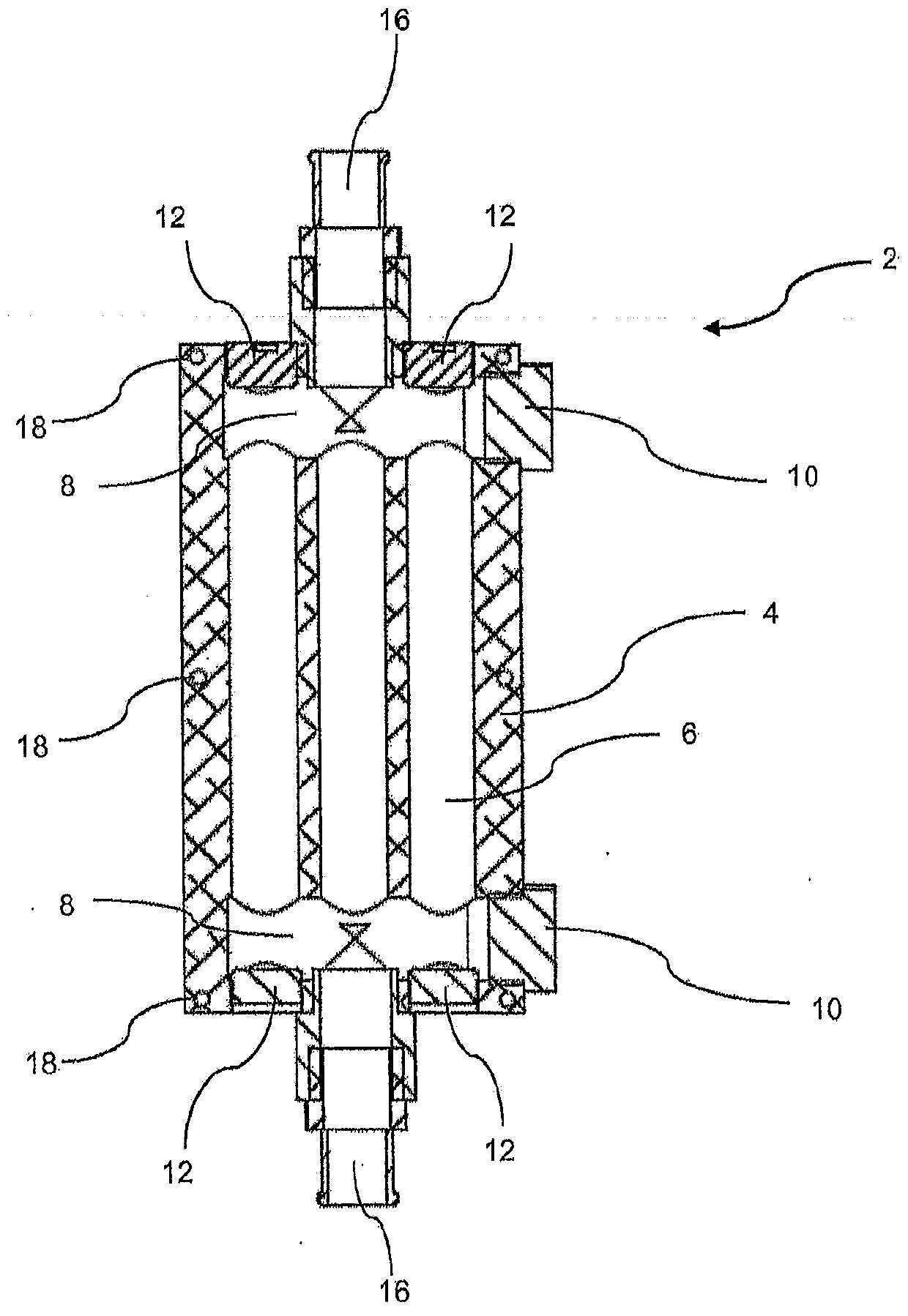

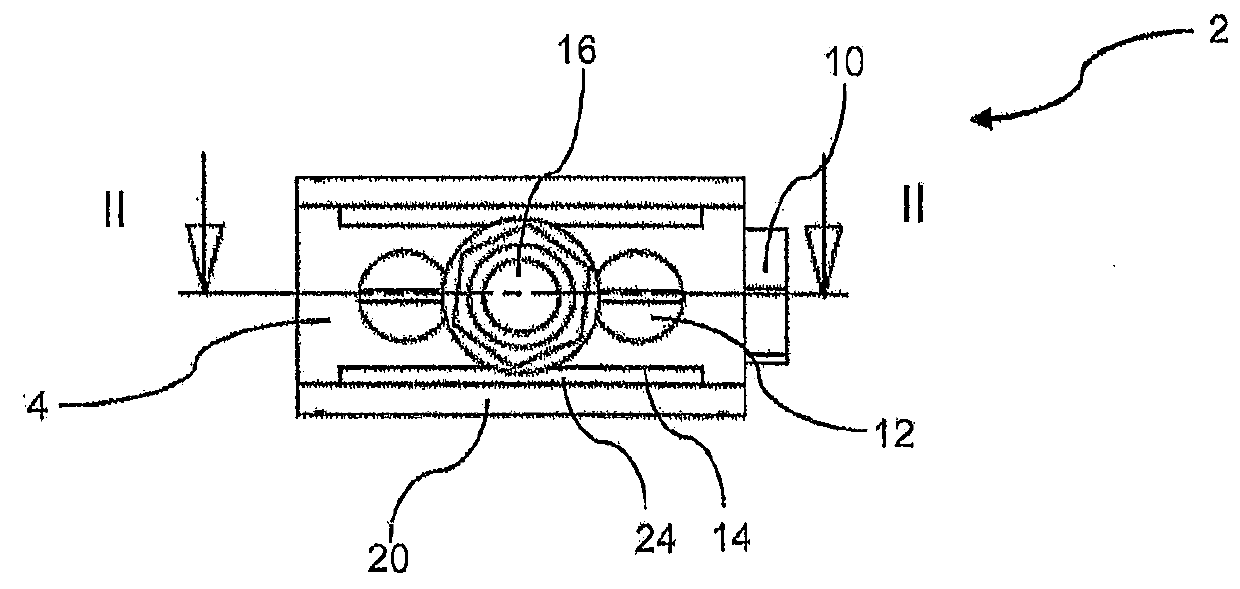

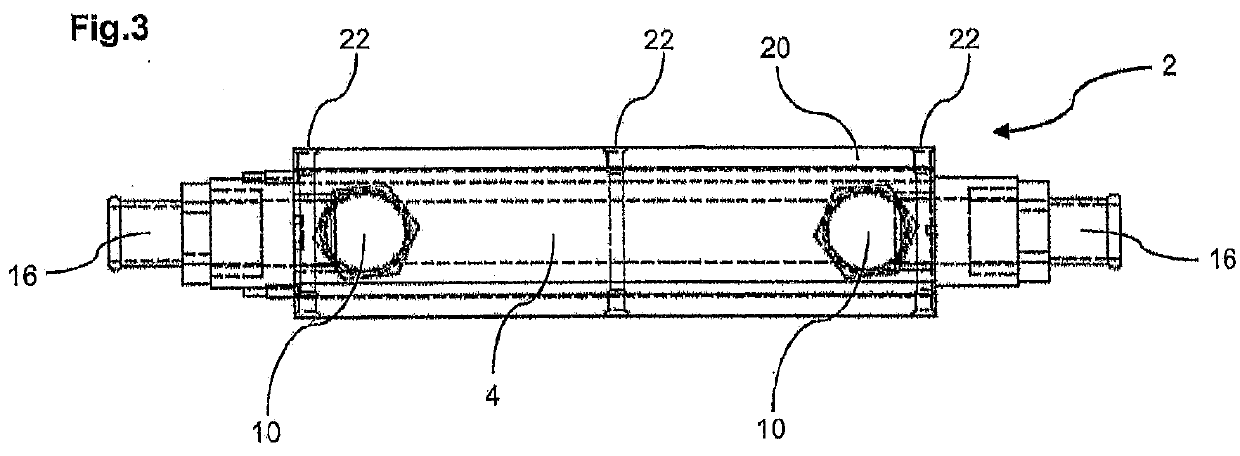

[0045]The fluid heating or preheating device shown in FIGS. 1 to 3 essentially comprises a solid member 4 of generally rectangular section having a through passageway for the fluid. The passageway comprises three straight and parallel channels 6 passing through the block from side to side. These channels are preferably produced by drilling.

[0046]The passageway also comprises two transverse channels 8, each being near one of the two ends of the longitudinal channels 6. These channels have the function to ensure a placing in communication of the longitudinal channels. These transverse channels are preferably made by drilling.

[0047]The heating body 4 can be made by extrusion with the longitudinal channels. The transverse channels can then be made by machining.

[0048]The longitudinal channels 6 open out on the front and back of the body 4. The areas of these faces where the lateral channels open are fitted with plugs 12, while the areas of said faces where the central channel opens are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com