Autonomous transports for storage and retrieval systems

a technology of automatic storage and retrieval system, applied in the field of material handling system, can solve the problems of inability to efficiently generate mixed goods pallets, conventional warehousing system, including conventional automated warehousing system, etc., and the inability of storing case units in carriers or on pallets to allow the retrieval of individual case units within those carriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

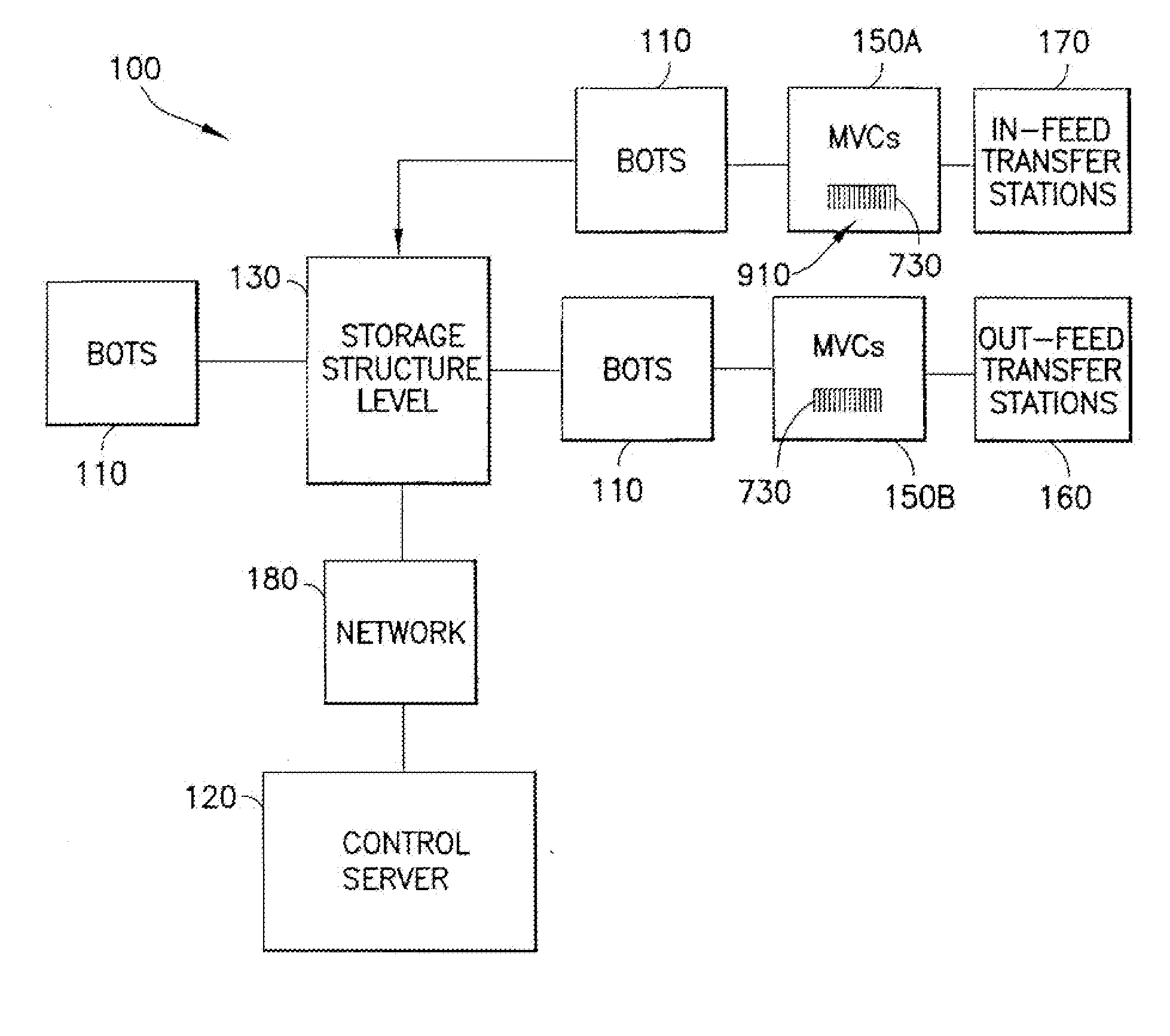

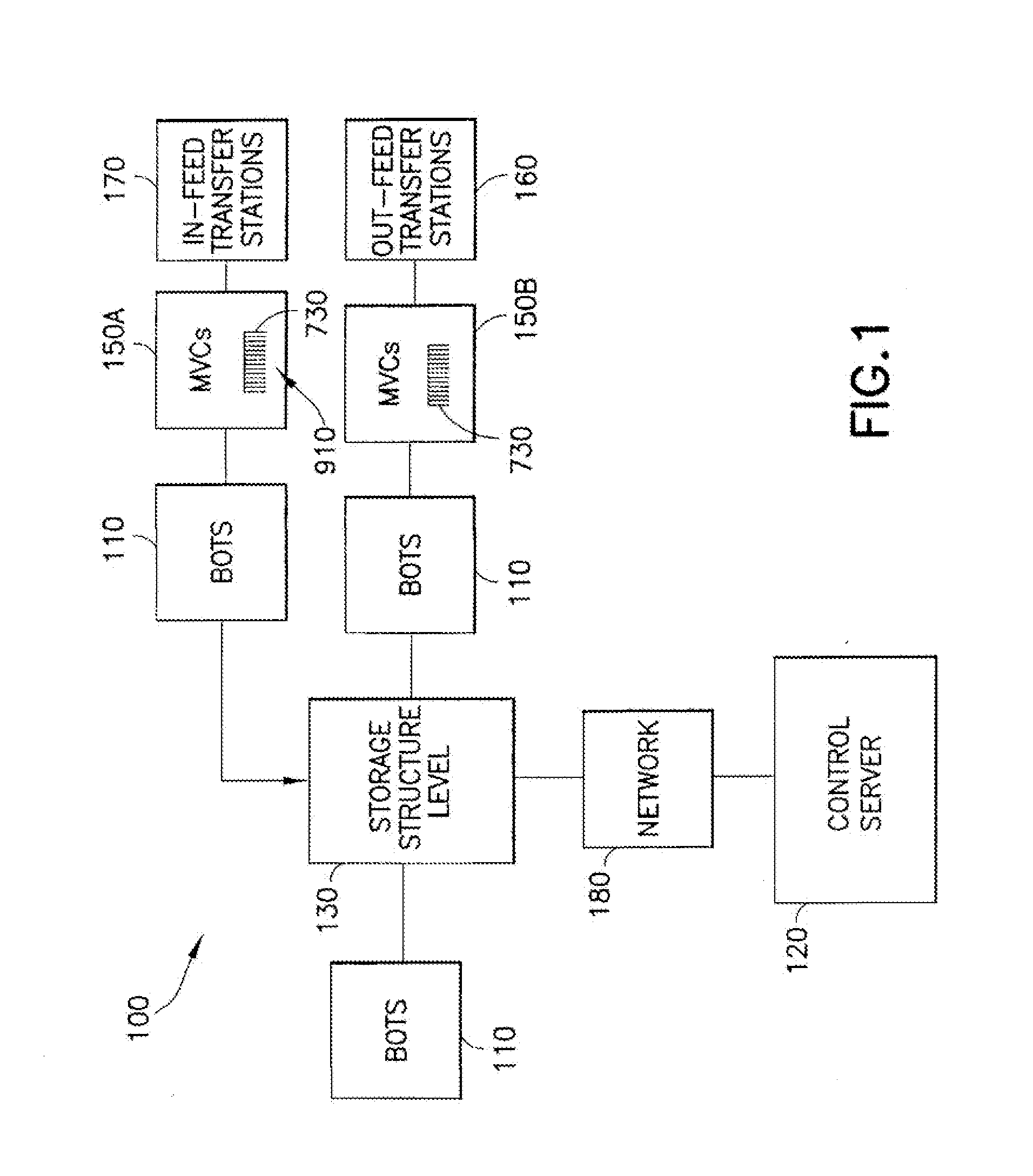

[0021]FIG. 1 generally schematically illustrates a storage and retrieval system 100 in accordance with an exemplary embodiment. Although the embodiments disclosed will be described with reference to the embodiments shown in the drawings, it should be understood that the embodiments disclosed can be embodied in many alternate forms. In addition, any suitable size, shape or type of elements or materials could be used.

[0022]In accordance with one exemplary embodiment the storage and retrieval system 100 may operate in a retail distribution center or warehouse to, for example, fulfill orders received from retail stores for case units (where case units as used herein means items not stored in trays, on totes or on pallets, e.g. uncontained). It is noted that the case units may include cases of items (e.g. case of soup cans, boxes of cereal, etc.) or individual items that are adapted to be taken off of or placed on a pallet. In accordance with the exemplary embodiments, shipping cases or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com