Driver current control apparatus and methods

a current control and drive motor technology, applied in the field of electronic circuits, can solve problems such as airbag deployment and squib firing, and achieve the effect of reducing the drive to the pass element and preventing excessive steady-state current flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

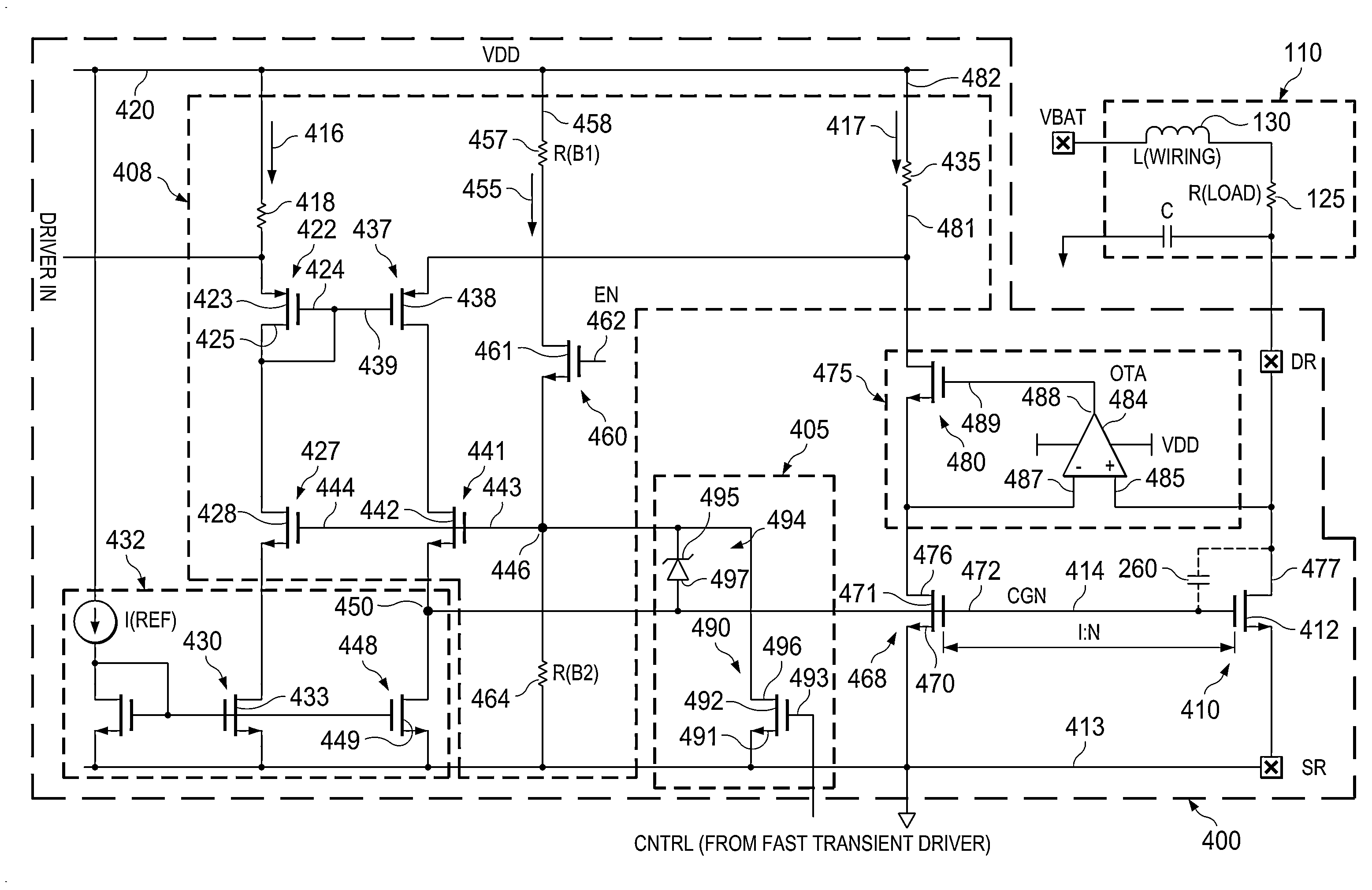

[0017]FIG. 4 is a schematic diagram of a general purpose driver and electronic current-limiting apparatus 400 according to various example embodiments of the invention. The driver and current-limiting apparatus 400 includes a steady-state over-current protection circuit and a fast transient switch 405 associated with a transient over-current protection circuit. A transient over-current control circuit portion of the transient over-current protection circuit is described below in conjunction with a detailed description of FIG. 5. FIG. 4 additionally illustrates an example driver load circuit 110 as previously described.

[0018]The driver and electronic current-limiting apparatus 400 includes a current regulating preamplifier 408. The current regulating preamplifier 408 establishes a desired level of current through current-bearing components of the load circuit 110, including load resistance 125 and inductance 130. The current-bearing components 125 and 130 of the load 110 will be refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com