Methods for converting plastic to wax

a technology of plastic and wax, applied in the field of plastic processing to convert plastic to wax, can solve the problem that the quality of polyethylene waxes derived from the thermal decomposition of polyethylene resin is typically inferior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

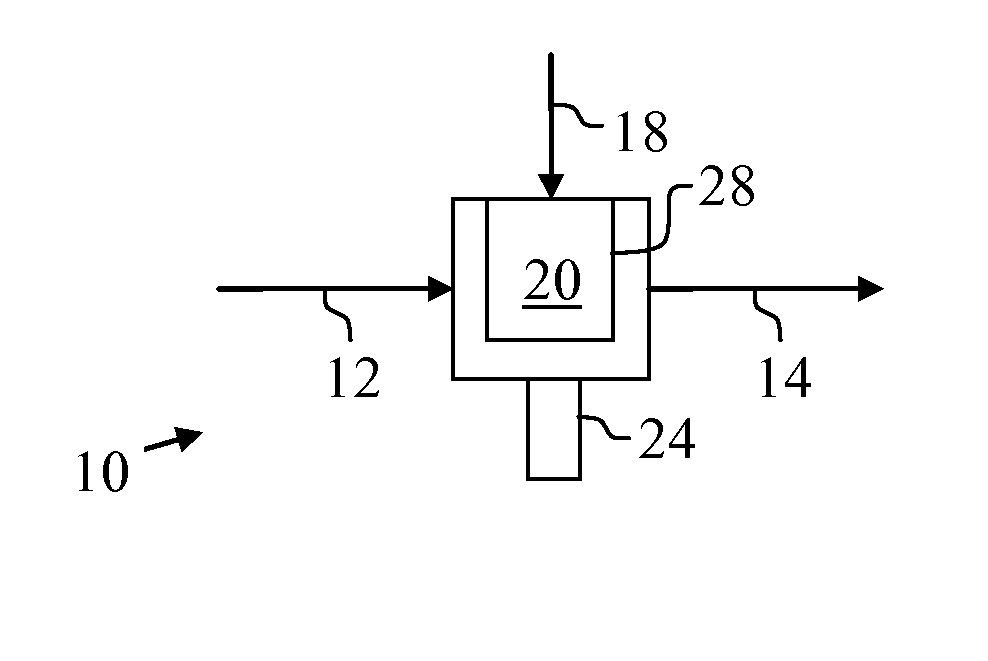

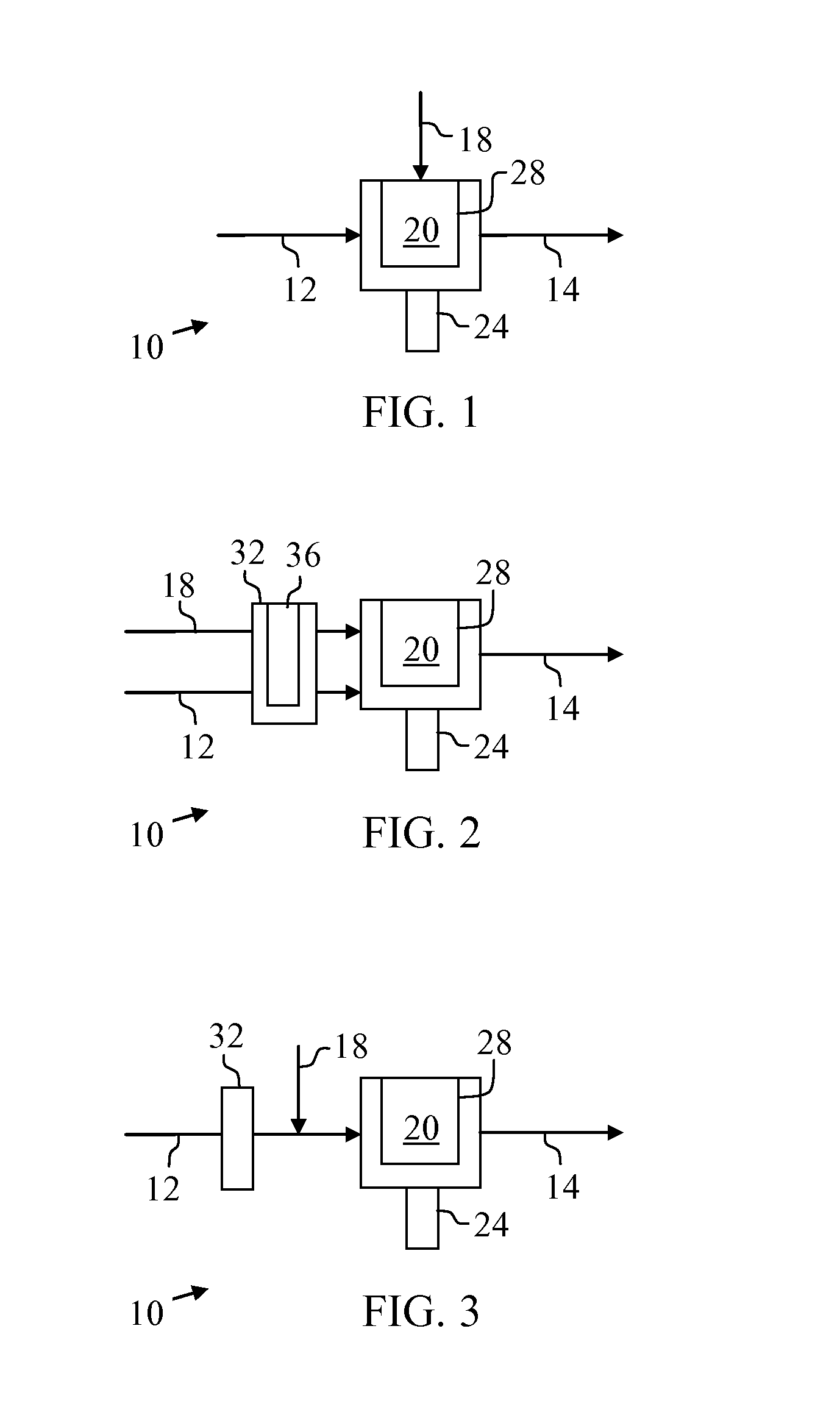

Image

Examples

Embodiment Construction

[0042]In a first example of an embodiment of a process for converting plastic to wax, 50 grams (g) of low density polyethylene (LDPE) was introduced to a stainless steel autoclave. The autoclave environment was purged with hydrogen at 40 standard cubic centimeters per minute (sccm) and the autoclave was heated to 135° C. for 60 minutes to melt the LDPE. Thereafter, the melted LDPE was heated to 405° C. for 30 minutes causing depolymerization of the LDPE under the continued hydrogen purge. The autoclave was then cooled to ambient temperature and the product wax was recovered. The composition of the product wax formed with hydrogen is set forth below in the TABLE.

[0043]In a second example of an embodiment of a process for converting plastic to wax, 50 or 20 grams (g) of low density polyethylene (LDPE) was introduced to a stainless steel autoclave. The autoclave environment was purged with nitrogen at 40 standard cubic centimeters per minute (sccm) and the autoclave was heated to 135° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com