Self-healing material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

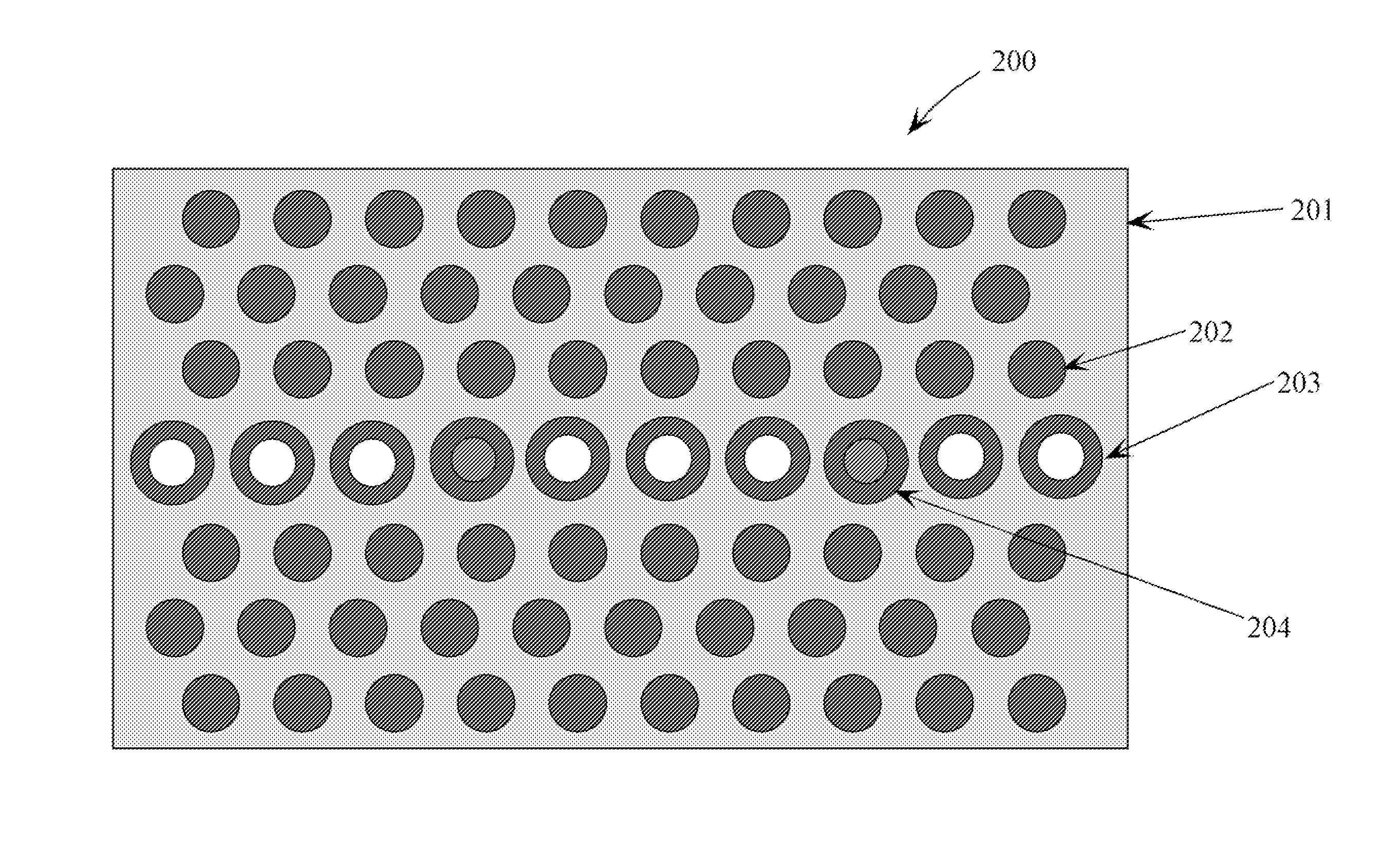

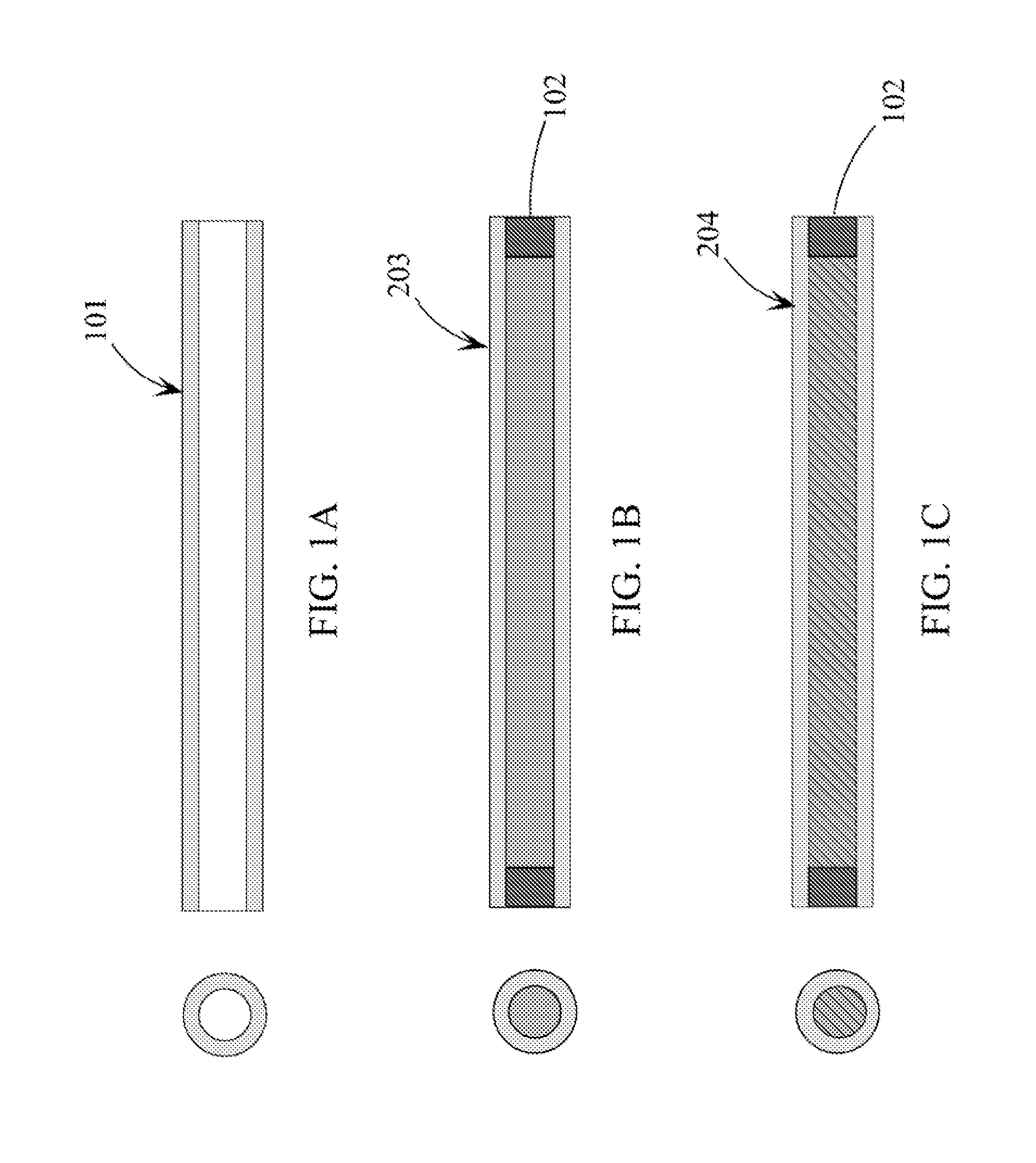

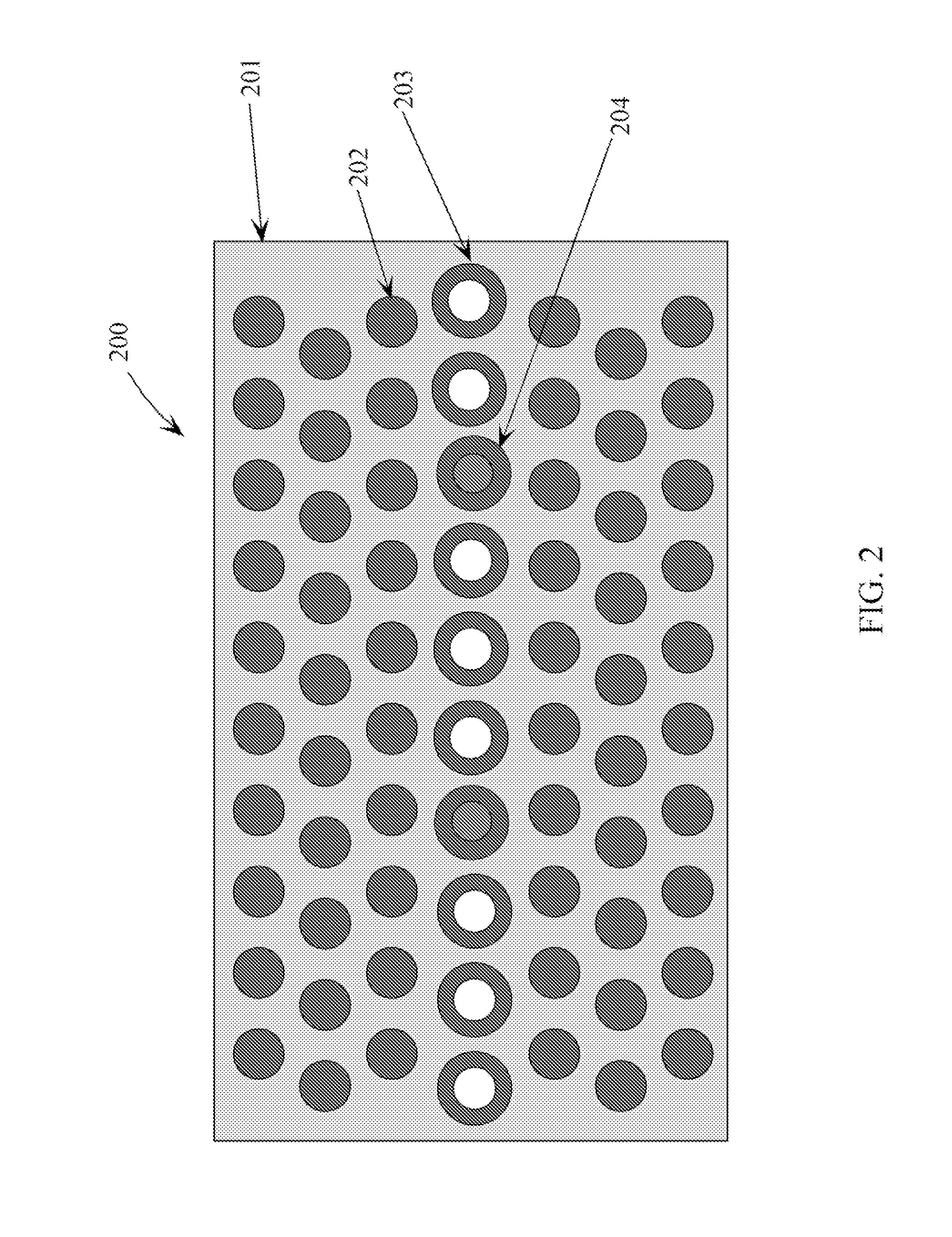

[0012]The inventors discovered that a vinyl ester resin and a methyl ethyl ketone peroxide (“MEKP”) catalyst can serve well as a self-healing material system for FRP composites due, at least in part, to the following advantages:

[0013]1. The vinyl ester can be cured at room temperature when contacted or mixed with a MEKP catalyst.

[0014]2. The viscosity of both the vinyl ester resin and the MEKP catalyst is very low (<2,000 centipoises), which allows hollow glass fibers or microcapsules to be easily filled with each.

[0015]It was found that the vinyl ester resin / MEKP catalyst self-healing system can increase the service life of the panel and recover performance soon after initial damage.

[0016]According to aspects of the present invention, an example is hereinafter described,

[0017]Part I. Base materials

[0018]1. Self-Healing Agent:

[0019]A vinyl ester resin (e.g., product designation Derakane 411-350) was commercially obtained from Ashland, Inc. The MEKP catalyst was commercially obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com