Air separation method and apparatus

a separation method and air technology, applied in lighting and heating apparatus, solidification, refrigeration and liquid storage, etc., can solve the problems of reduced oxygen recovery, increased energy added to the plant by the cold compressor, and increased refrigeration demand, so as to reduce energy consumption, increase oxygen recovery, and increase oxygen recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

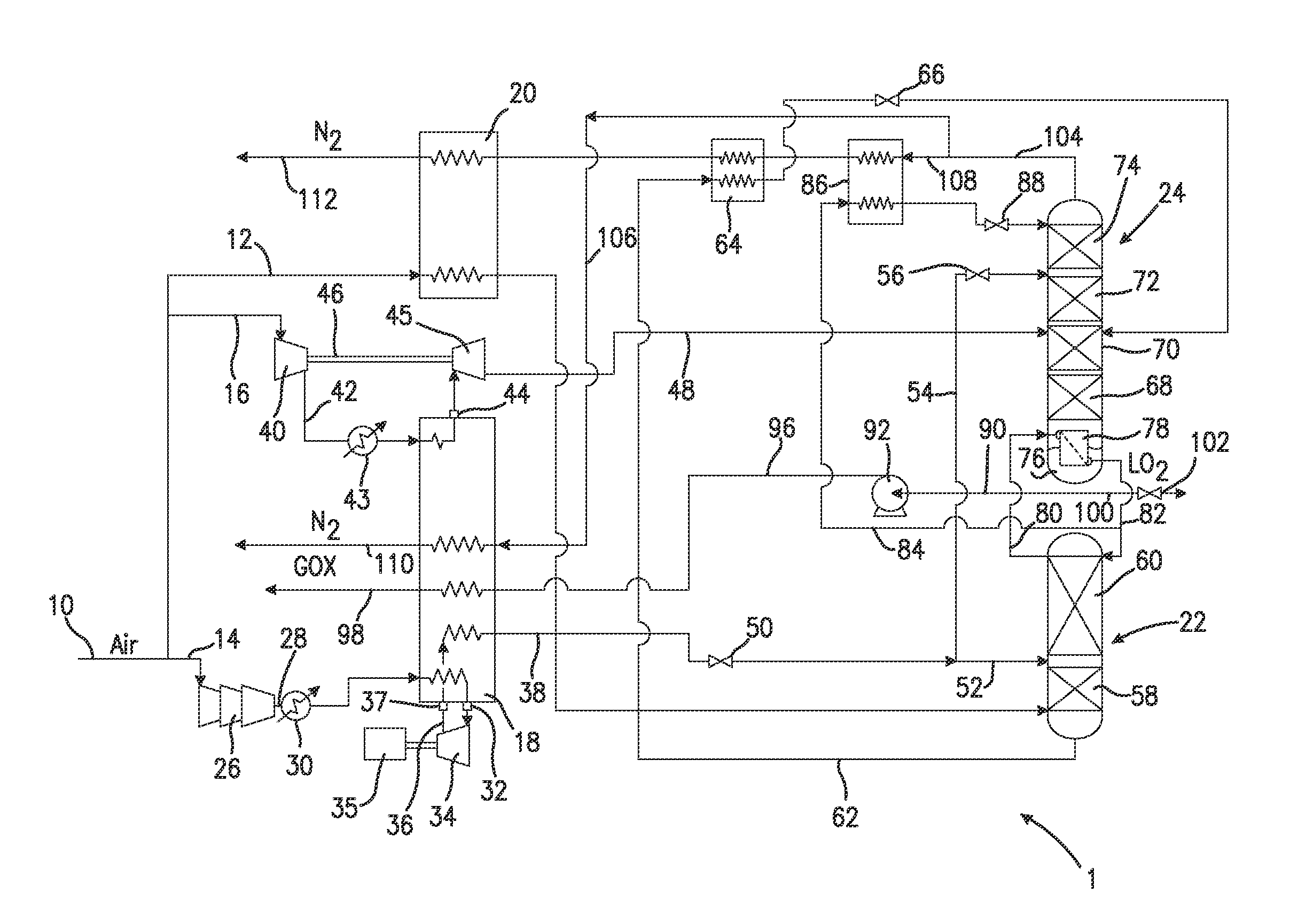

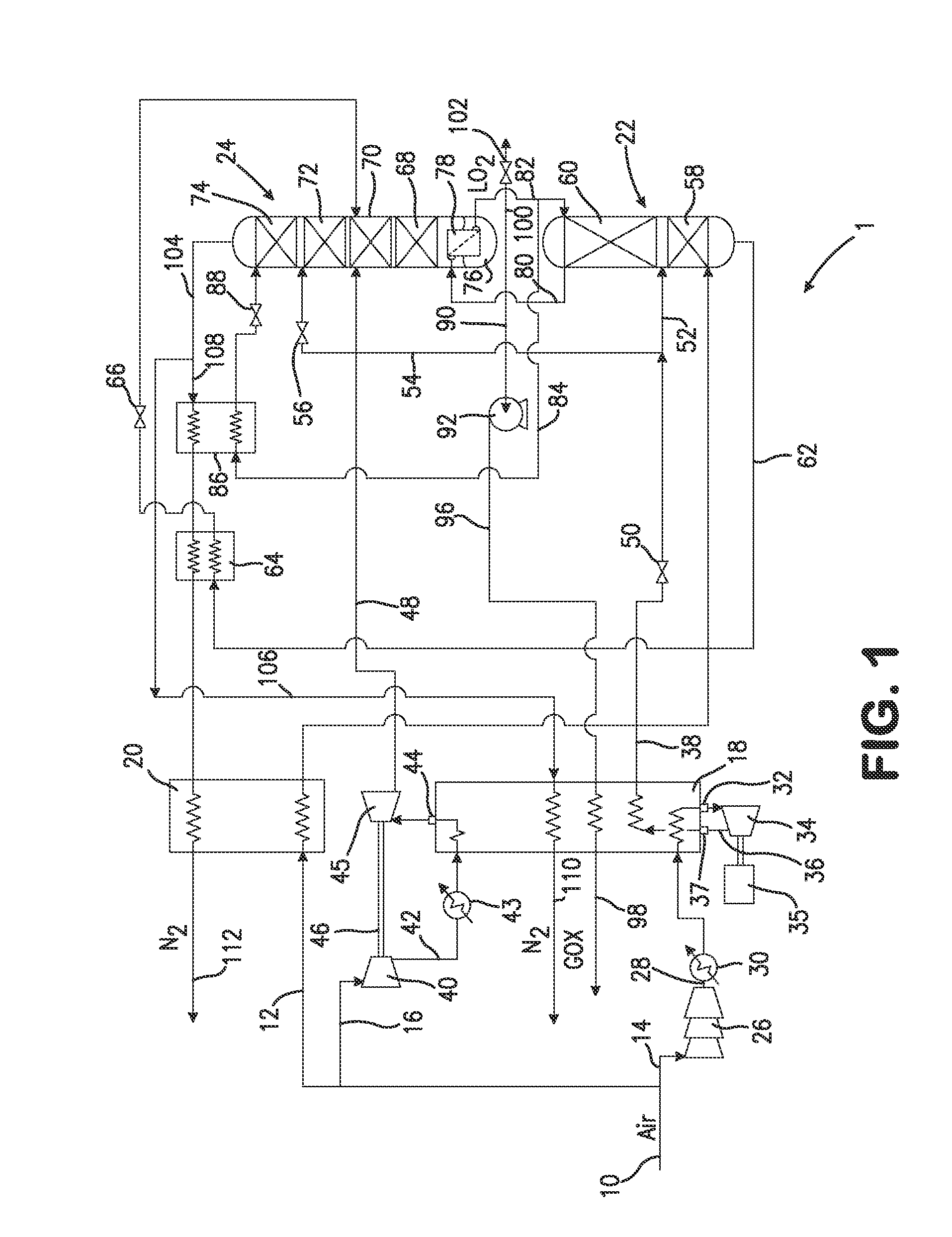

[0034]With reference to the FIG. 1, an air separation plant 1 is illustrated that is designed to produce an oxygen product stream 98 at pressure. In air separation plant 1, a compressed and purified air stream 10 is divided into a first compressed stream 12, a second compressed stream 14 and a third compressed stream 16. Although not illustrated, compressed and purified air stream 10 can originate from a main air compressor that compresses the air to a pressure of between 4.5 and 7.0 bar(a) and then purified of higher boiling contaminants by means of an adsorption bed system having known adsorbent beds operating in an out-of-phase cycle, typically, a temperature swing cycle. Such higher boiling contaminants are those that would solidify or concentrate at cryogenic temperatures; for instance, carbon dioxide, water vapor and hydrocarbons. The air separation plant 1 could be part of an enclave of such plants or similar plants; and therefore, the compressed and purified air stream 10 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com