Automated construction machinery and method

a construction machinery and automatic technology, applied in the field of automatic construction machinery, can solve the problems of requiring great precision for accuracy, efficiency and aesthetics, and the above described paving machine would not provide the block-construction system, and achieve the effects of reducing labor costs, reducing or eliminating difficult and labor-intensive aspects, and fast and more accurate installation of construction materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

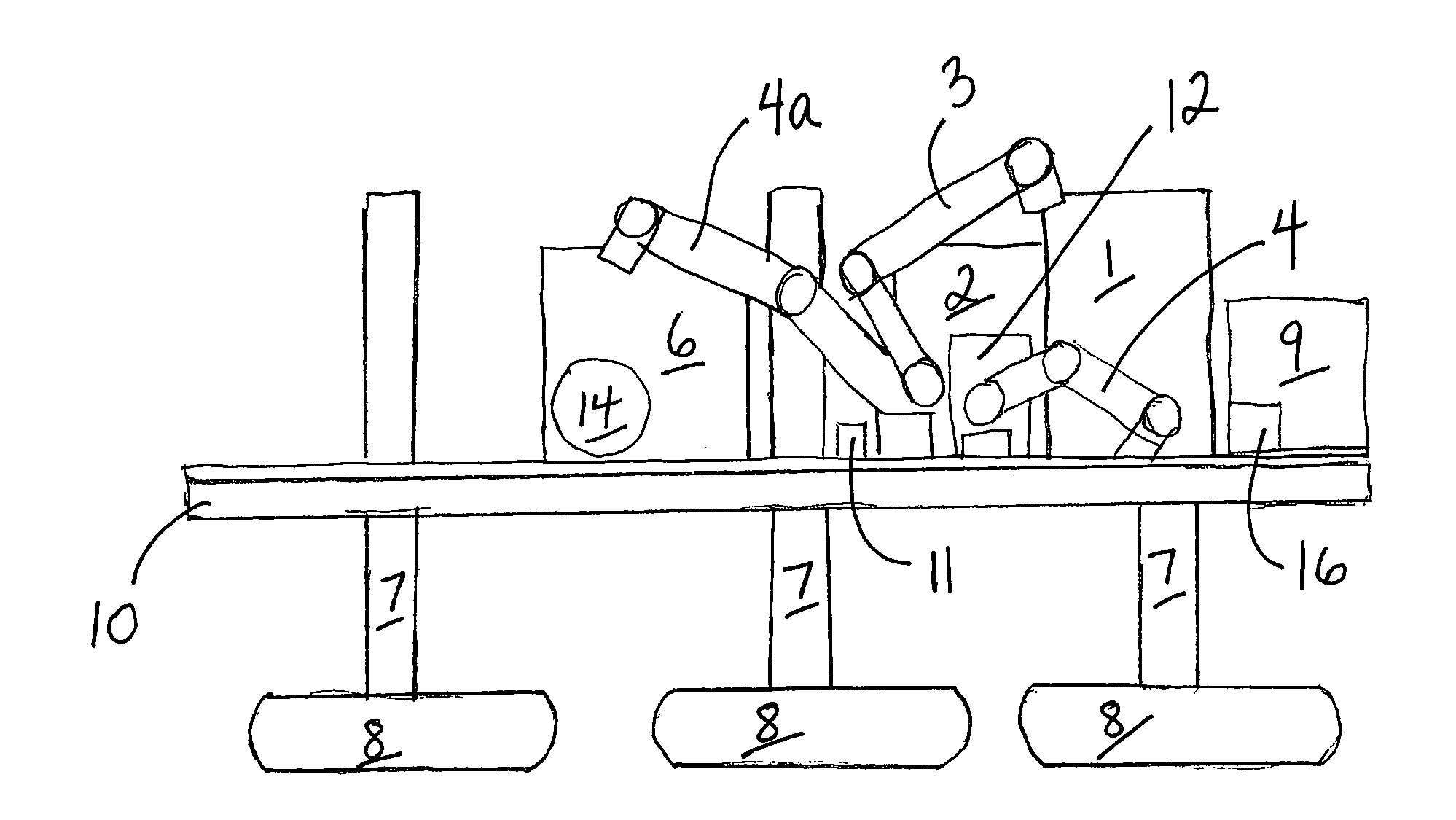

[0067]A 200 feet by 400 feet rectangular building having control joints at 20 foot centers is constructed in the following manner.

[0068]1) Building dimensions are programmed into a computer.

[0069]2) A 3-D stringless guidance system (e.g. Leica system) is set and input offset points and bench marks are recorded.

[0070]3) The subject construction apparatus is positioned and set-up with CMU's and mortar. A typical load for each may be 100 blocks or 500 bricks per cube (8 feet cubed). Typical blocks may be 8 in.×8 in.×16 in.

[0071]4) To load the machine:[0072]Mortar is mixed at a mixer and pumped into a tank that holds the prepared mortar. The tank has an auger and a water inlet to temper the mortar, keeping the mortar workable. A typical load of mortar may be 25 to 100 gallons[0073]CMU's are loaded on machine by forklift at the designated place.

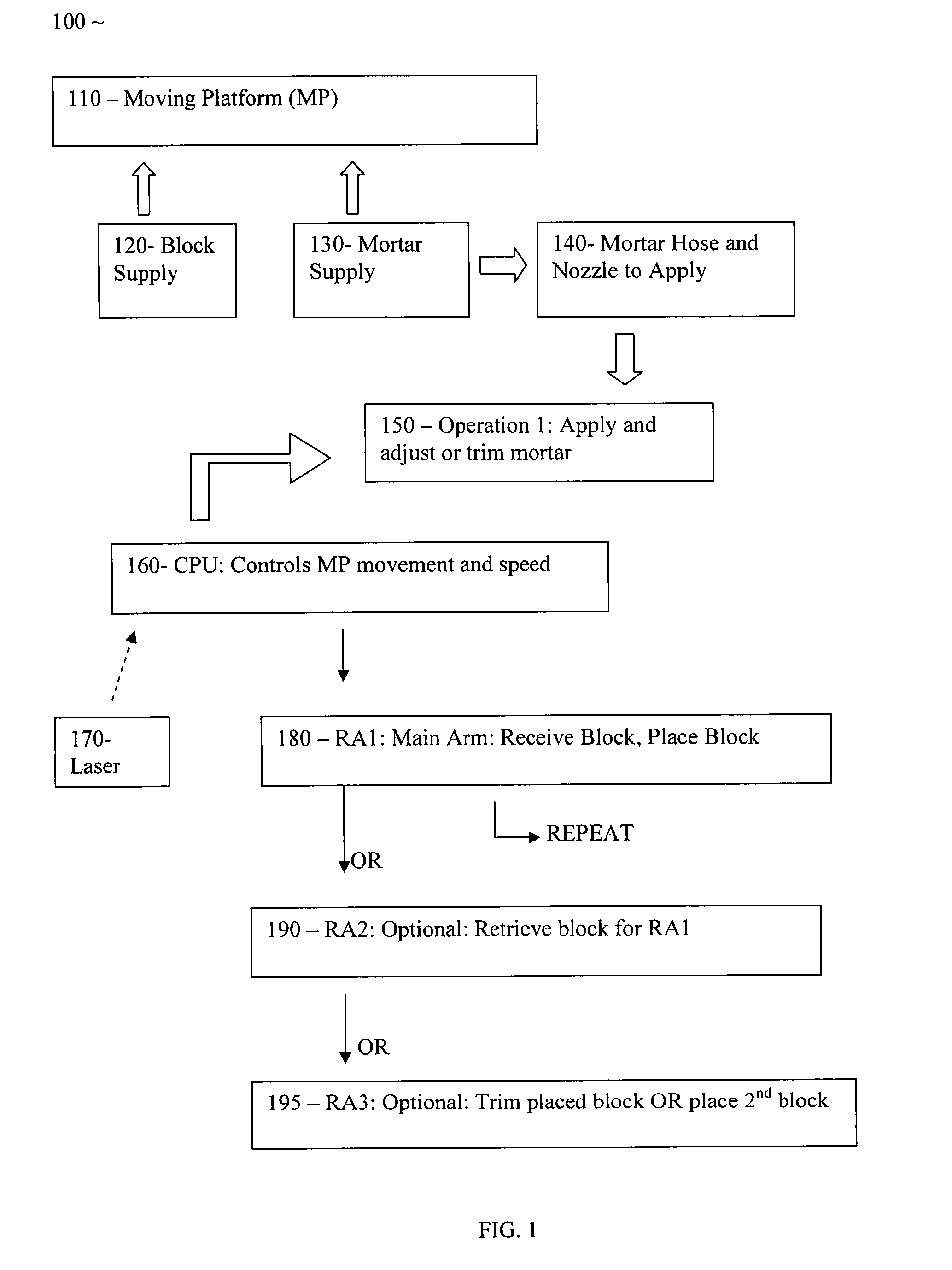

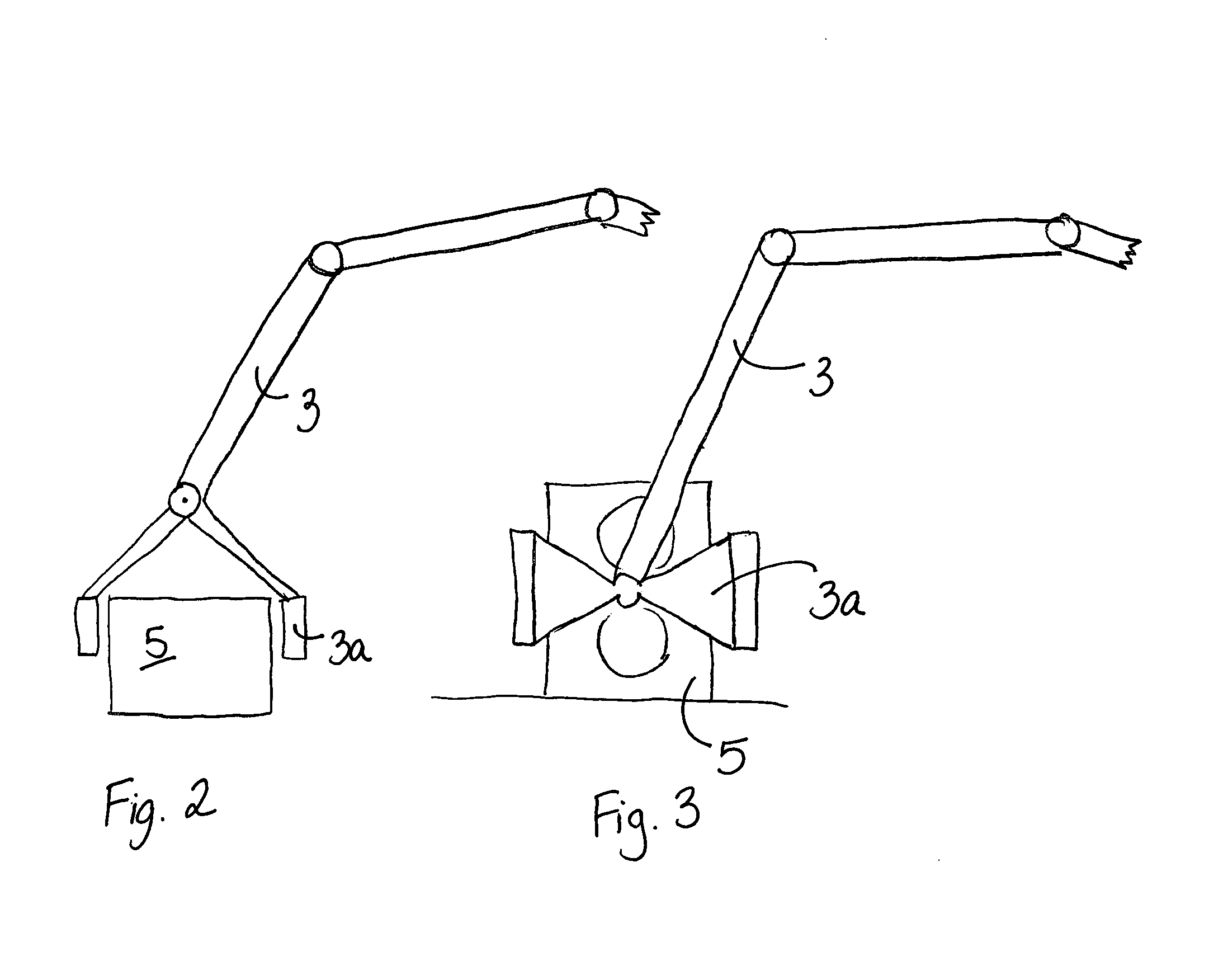

[0074]5) The apparatus starts to lay the block. There will be one or more robotic arms to do this job.[0075]One arm applies mortar to head and be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com