Vapor-deposited foamed body

a foamed body and vapor-deposited technology, which is applied in the field of vapor-deposited foamed bodies, can solve the problems of reducing the gas-barrier property, the quality of the contents in the container is effectively prevented from being deteriorated, and the gas-barrier property is effectively reduced. , the effect of preventing the quality of the contents in the container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

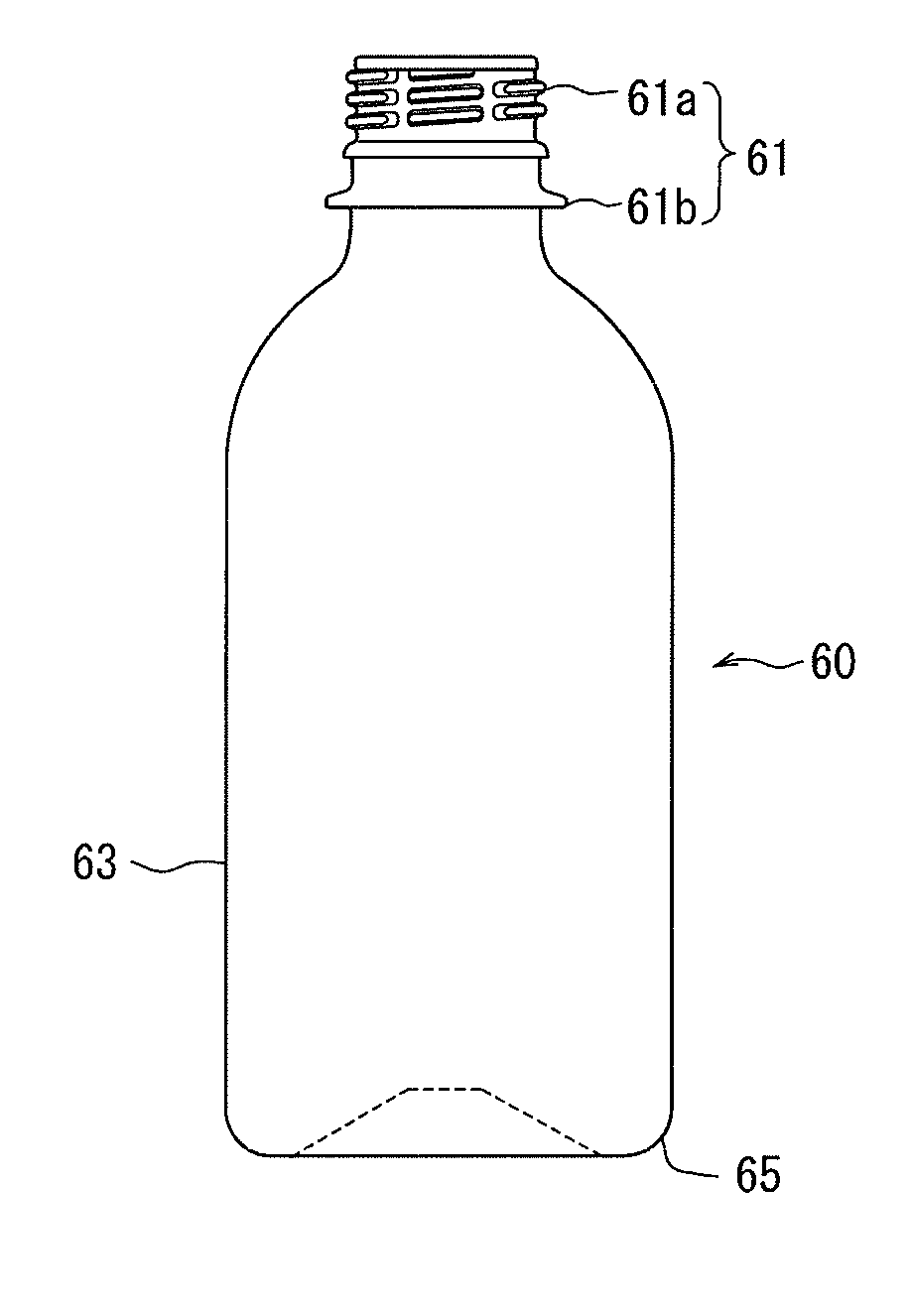

[0111]A PET resin for bottle containing 0.15% of a nitrogen gas and having an intrinsic viscosity (IV) of 0.84 dL / g was injected into a mold cavity maintaining a pressure therein of 5 MPa by blowing high-pressure air and a temperature of 30° C. and, thereafter, the pressure therein was maintained at 50 MPa for 18 seconds. After another 12 seconds have passed, the mold was opened. There was obtained a preform for container of the shape of a test tube in a substantially unfoamed state in which the gas has been dissolved and having a smooth surface and an overall length of about 110 mm.

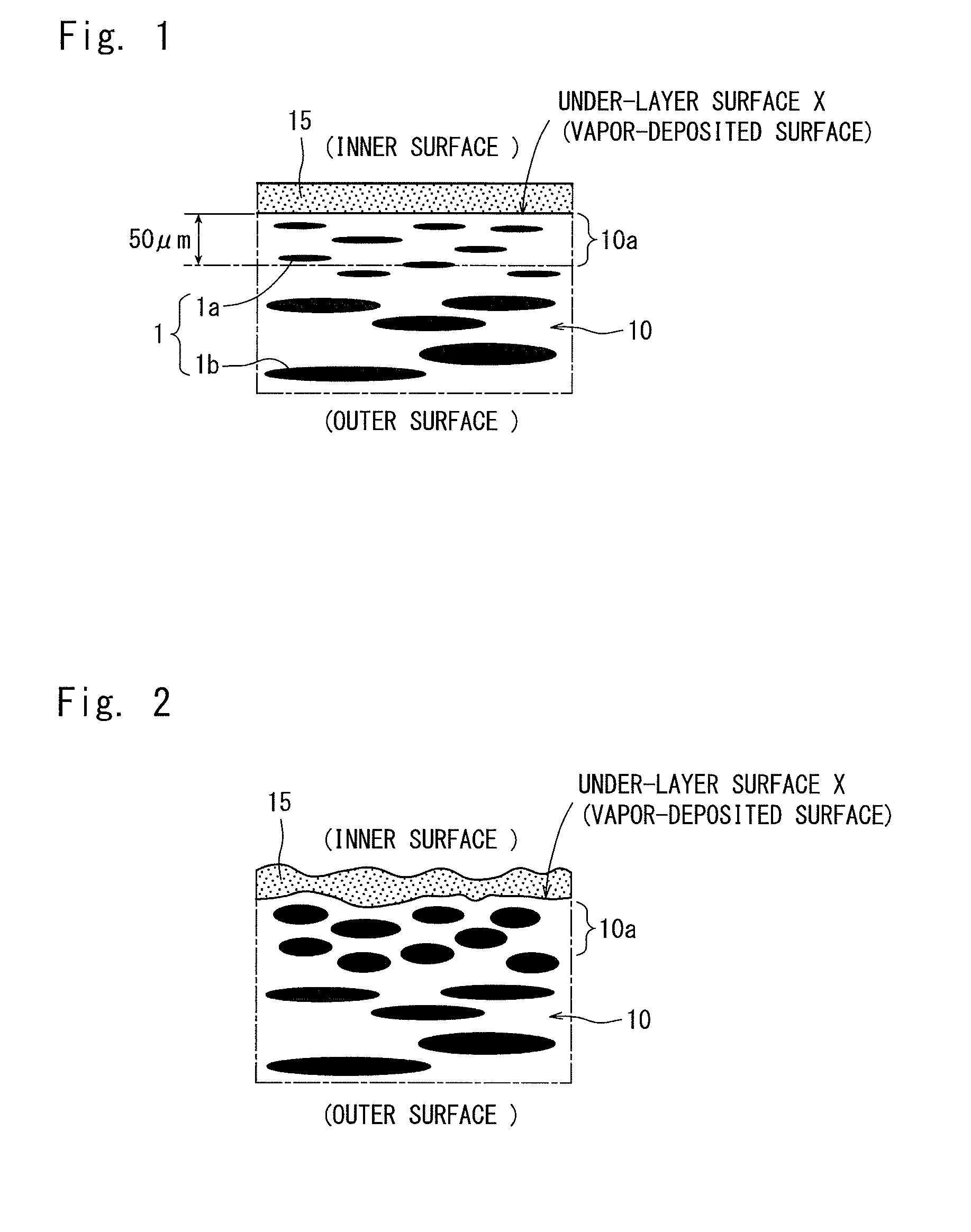

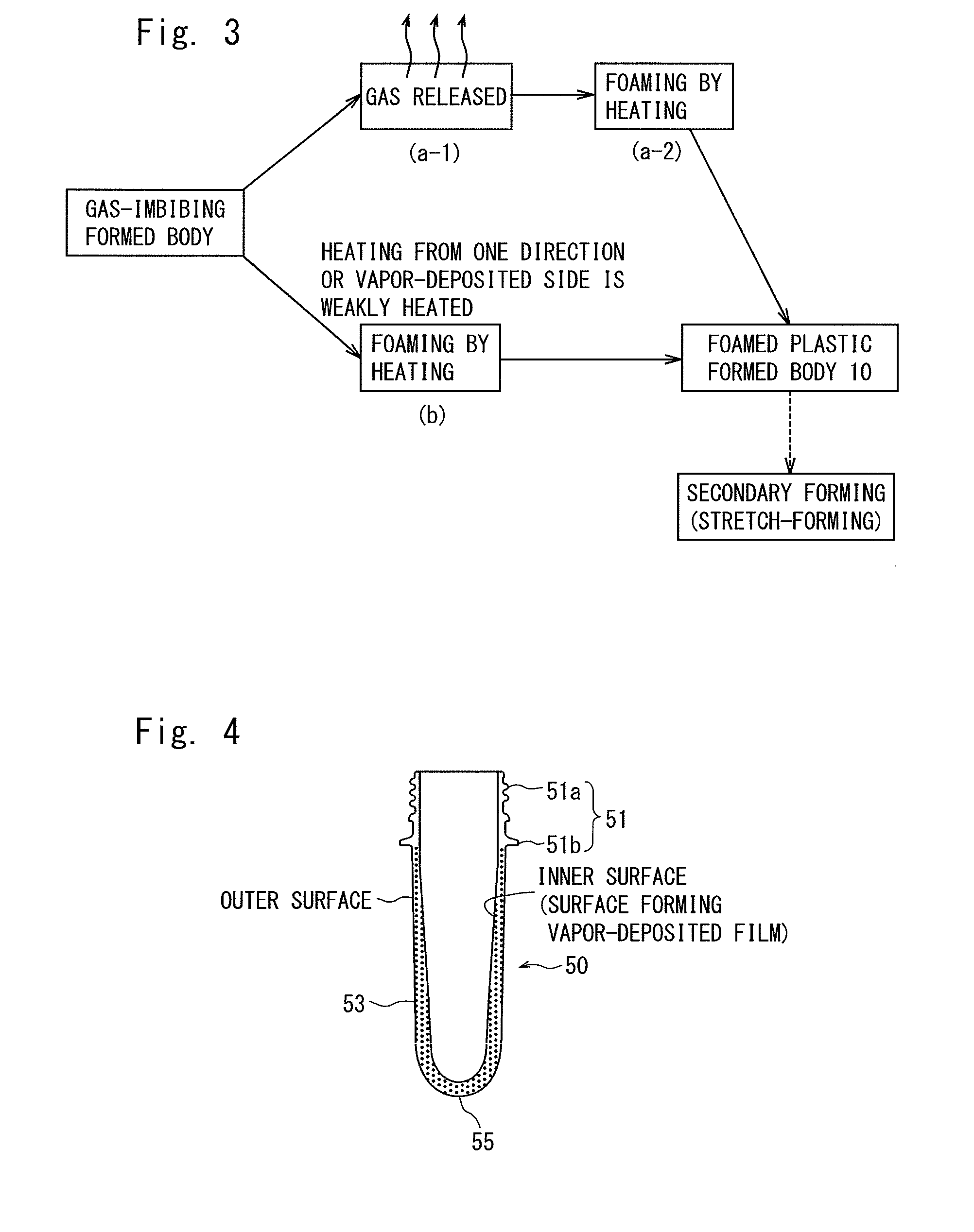

[0112]The preform was, further, heated and foamed, and was directly blow-formed to obtain a foamed blow-formed bottle having a thickness in the body portion of about 600 μm and a capacity of about 500 ml. The heating was conducted from both the outer surface side and the inner surface side, and the heating condition was so adjusted that the temperature was 99° C. on the inner surface side of the preform ...

example 2

[0116]A preform was formed, a bottle was formed, and a film was vapor-deposited thereon in the same manner as in Example 1 but so adjusting the heating conditions that the temperature was 102° C. on the inner surface side of the preform of when it was being heated.

[0117]The amount of oxygen that has permeated through the obtained bottle having its inner surface vapor-deposited was as good as 0.004 cc / bottle / day (before the vapor deposition, the amount was 0.06 cc / bottle / day).

[0118]The average porosity was 19% in the inner surface layer portion of the bottle body portion, and was 24% in the outer surface layer portion thereof.

example 3

[0119]A preform was formed, a bottle was formed, and a film was vapor-deposited thereon in the same manner as in Example 1 but so adjusting the heating conditions that the temperature was 104° C. on the inner surface side of the preform of when it was being heated.

[0120]The amount of oxygen that has permeated through the obtained bottle having its inner surface vapor-deposited was as good as 0.007 cc / bottle / day (before the vapor deposition, the amount was 0.07 cc / bottle / day).

[0121]The average porosity was 25% in the inner surface layer portion of the bottle body portion, and was 32% in the outer surface layer portion thereof.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com