Gas turbine combined cycle system

a combined cycle and gas turbine technology, applied in steam engine plants, machines/engines, mechanical equipment, etc., can solve the problems of limiting the effect of higher firing temperature, air affecting gas turbine performance, and air used to cool the stage 1 rotor not producing useful shaft work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

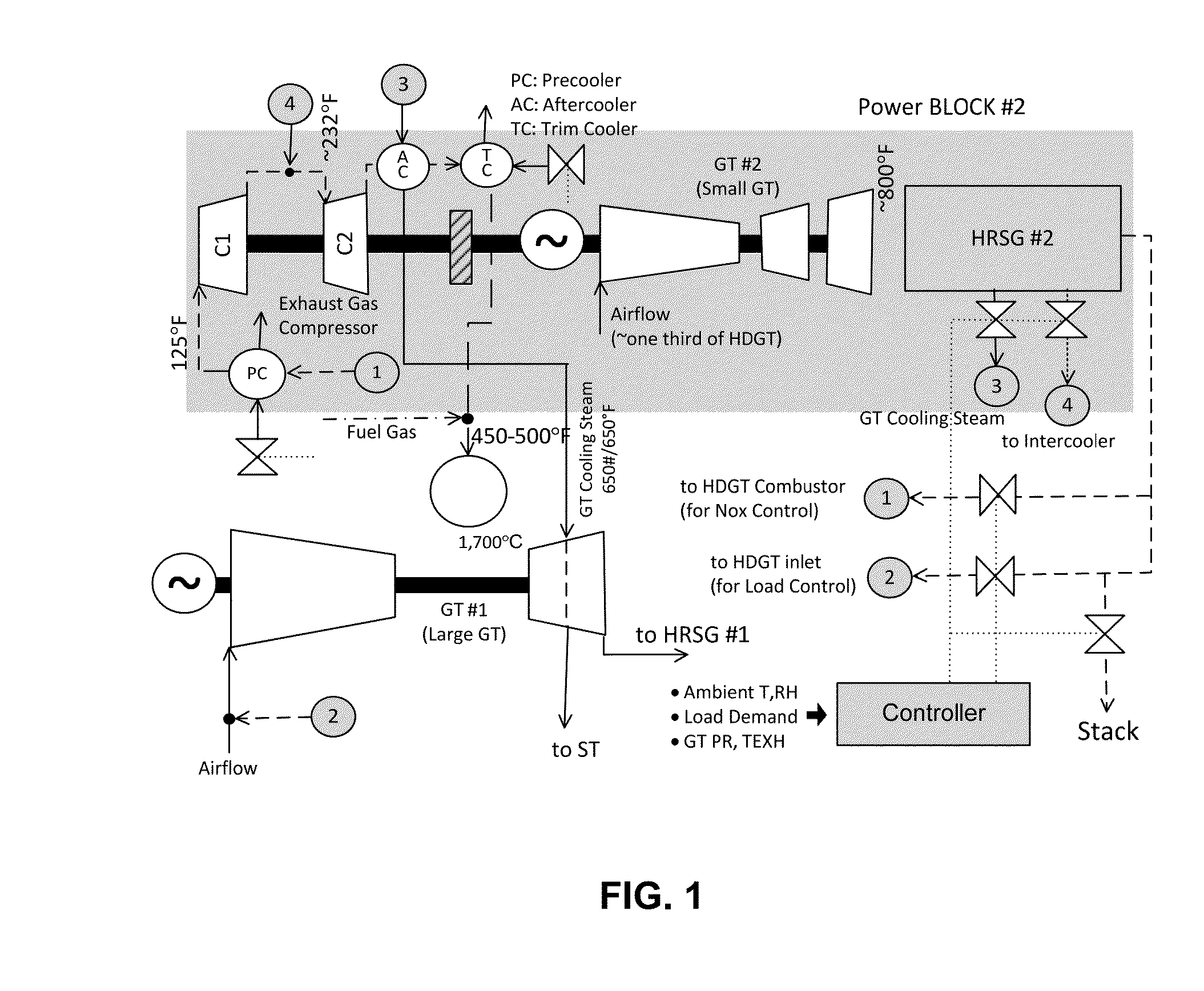

[0043]An exemplary embodiment as shown in FIG. 1 has two power blocks. Power Block 1 comprises a first gas turbine (GT #1) and a steam turbine (ST), labeled but not shown as a separate block, on a single shaft driving a single generator or each driving its own generator in a multi-shaft configuration. Power Block 2 comprises a second gas turbine (GT #2) and an intercooled, two-stage flue gas compressor (FGC) on a single shaft with a single electric generator.

[0044]The gas turbine prime mover of each power block burns fuel and is thermally coupled to a heat recovery steam generator HRSG via the exhaust of the respective prime mover, i.e., GT #1 supplies hot exhaust gas to HRSG #1 (labeled but not shown as a separate block) and GT #2 supplies hot exhaust gas to HRSG #2.

[0045]The shaft configuration of Power Block 2 is not critical to the invention. That is, Power Block 2 can be a single-shaft or multi-shaft configuration. In a multi-shaft configuration, the FGC can be driven by an ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com