Method for polishing edge of glass substrate of display panel

a technology of display panels and glass substrates, applied in the field of precision machining, can solve the problems of glass chips flying and attaching to a non-polished area, cleaning the glass substrate, and the inability to protect the non-polished area of the glass substrate from surface damage, so as to achieve the effect of improving operation efficiency, facilitating the operation, and effectively protecting the non-polished area from contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]To further expound the technical solution adopted in the present invention and the advantages thereof, a detailed description is given to a preferred embodiment of the present invention and the attached drawings.

[0047]Referring to FIGS. 4-6, the present invention provides a method for polishing edge of glass substrate of display panel, which comprises the following steps:

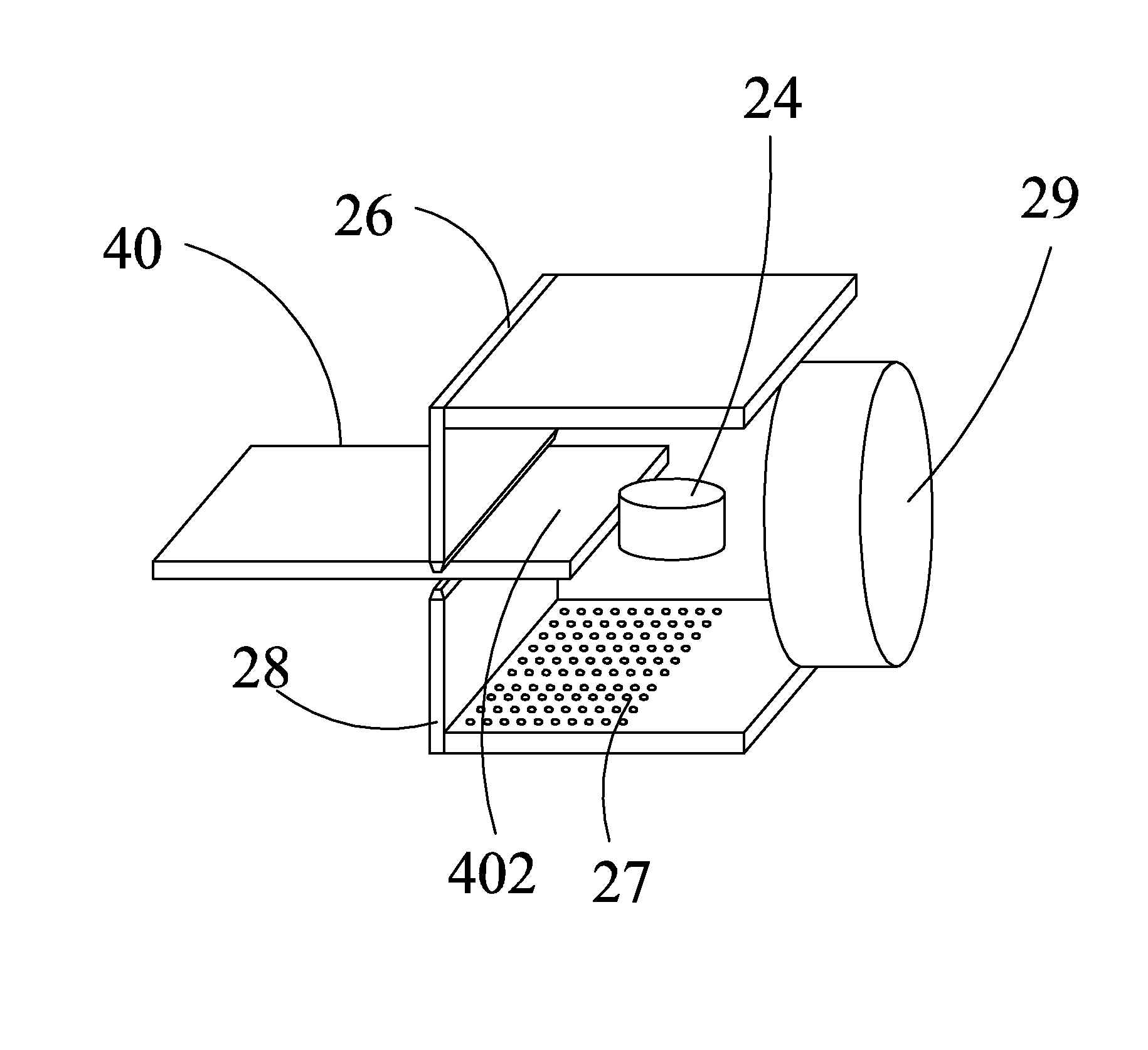

[0048]Step 1: conveying a glass substrate 40 of a display panel to be polished to a polishing device and positioning the glass substrate 40 for being subsequently polished by a grindstone 24 of the polishing device.

[0049]The glass substrate 40 comprises a polished area 402 and a non-polished area 404 located beside the polished area 402. The grindstone 24 of the polishing device is set in contact with the polished area 402. Step 1 can be carried out with any known technique and the polishing device can be a known device. The operation of positioning includes fixing the glass substrate 40 at a polishing positio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| elastic | aaaaa | aaaaa |

| transparent conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com