Cathodic protection current distribution method and apparatus for corrosion control of reinforcing steel in concrete structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]This invention relates to protection and corrosion prevention of reinforced concrete structures using mixed-metal-oxide (MMO) coated precious-metal tape anodes. In the preferred embodiments, the anodes are attached to a concrete surface using a non-conductive adhesive and covered with a semi-conductive layer to provide cathodic protection or chloride removal. As such, the bare metal surface of the tape is fixed on the concrete surface using a non-conductive adhesive, such that the MMO-coated metal surface of the tape is exposed.

[0019]The substrate metal tape anode may be composed of titanium, tantalum, zirconium, or niobium. However, the most preferred metals are titanium or titanium alloys because of the corrosion resistance and availability. The tape anode width is preferably over 5 mm, and the thickness is in the range of 0.001 mm to 1 mm, preferably between 0.1 mm to 0.3 mm.

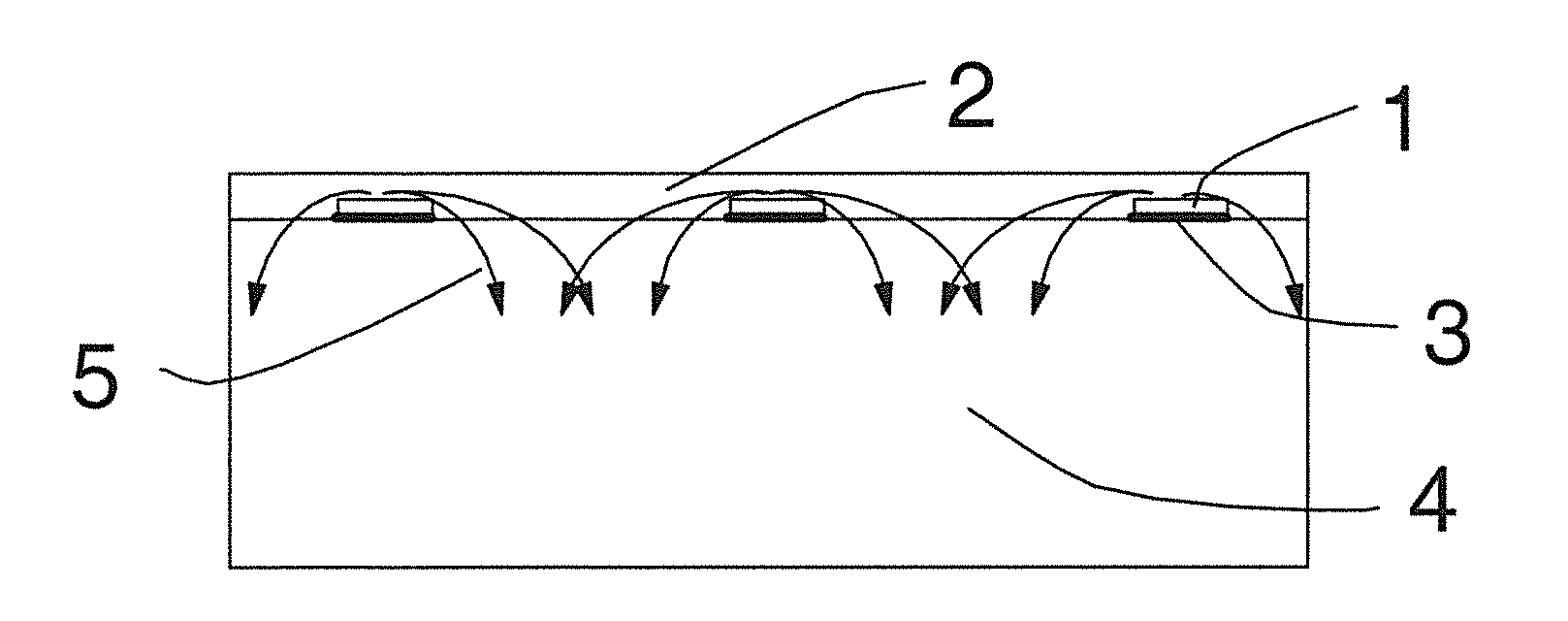

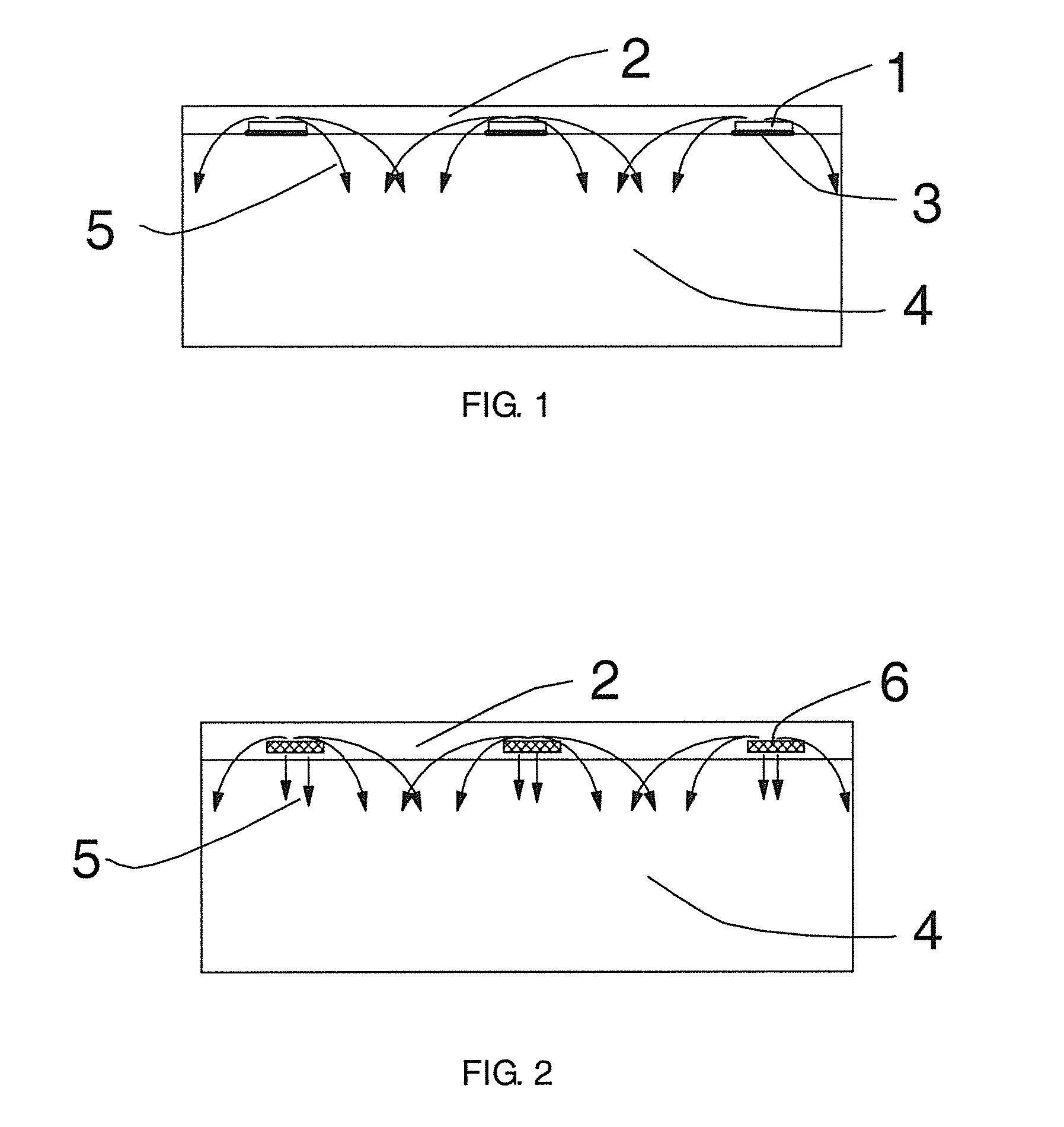

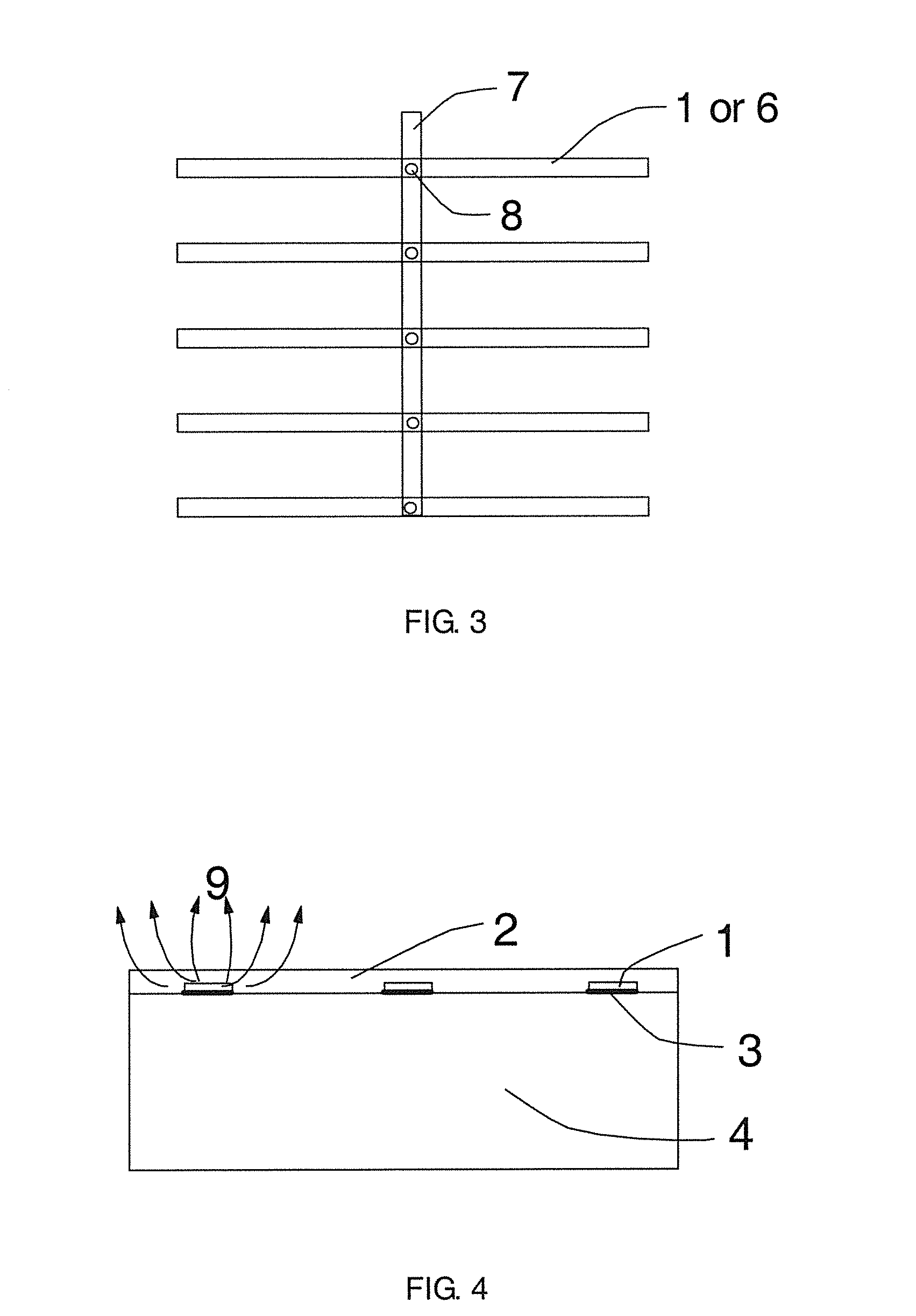

[0020]FIG. 1 is a simplified cross-sectional diagram showing a metal tape anode 1 attached to concre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com