Black smoke burning and purifying apparatus for vehicle exhaust

a technology of black smoke and purification apparatus, which is applied in the direction of mechanical equipment, exhaust treatment, machines/engines, etc., can solve the problems of improper operation of diesel engines, affecting the emission of diesel engine exhaust, etc., and achieves the reduction of flow rate, speed, and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

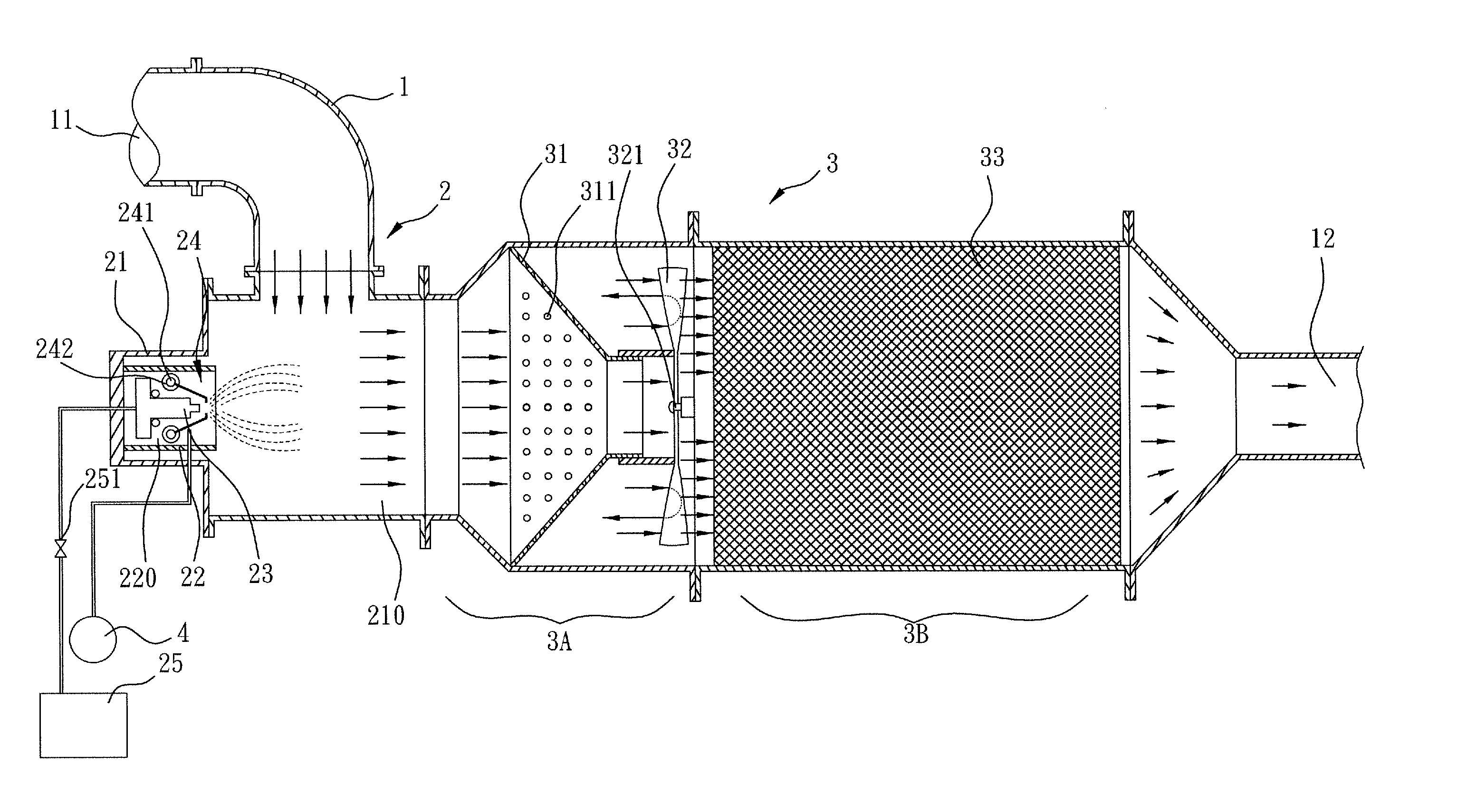

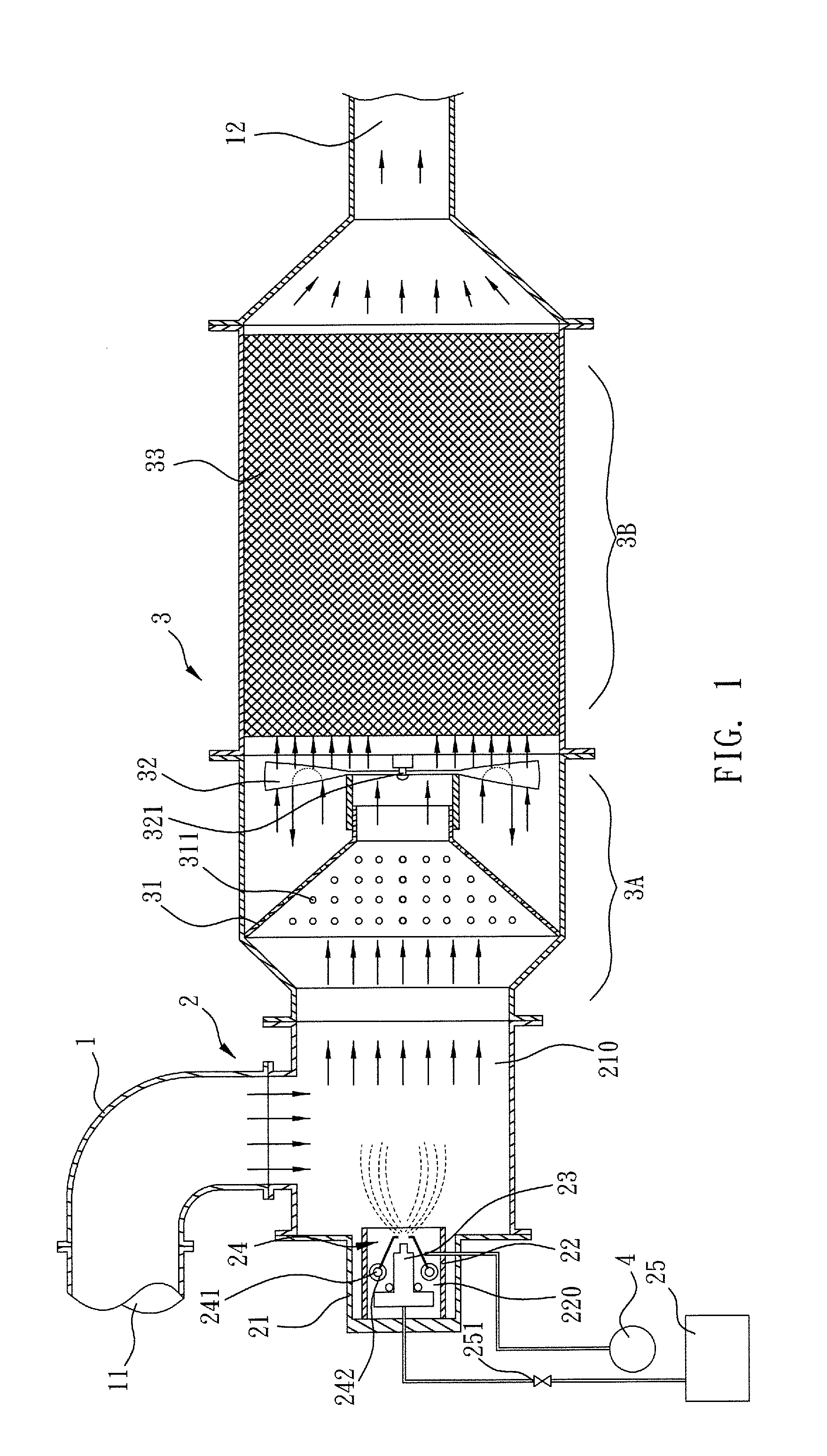

[0011]As shown in FIG. 1, an improved black smoke burning and purifying apparatus for a vehicle exhaust of the present invention comprises a burning system 2 and an emission smoke buffered filtering system 3 fluidly connected in sequence. In which, the burning system 2 comprises an external pipe 21 with a burning chamber 210 in an internal thereof and a side wall of the external pipe 21 is fluidly connected to an intake end 11 of the vehicle exhaust 1. The internal of the external pipe 21 comprises a cavity 22 having a compartment of 220 formed therein. The cavity 220 comprises an oil atomized nozzle 23 and at least one igniter 24. The oil atomized nozzle 23 is fluidly connected to a fuel pump tank 25 arranged at the outer of the external pipe 21 via a conduit and the conduit is further provided with a solenoid valve 251. The compartment 220 of the cavity 22 is fluidly connected to a pneumatic pump 4 via another conduit and the pneumatic pump 4 is able to deliver air from the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com