Heat-Exchange Apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

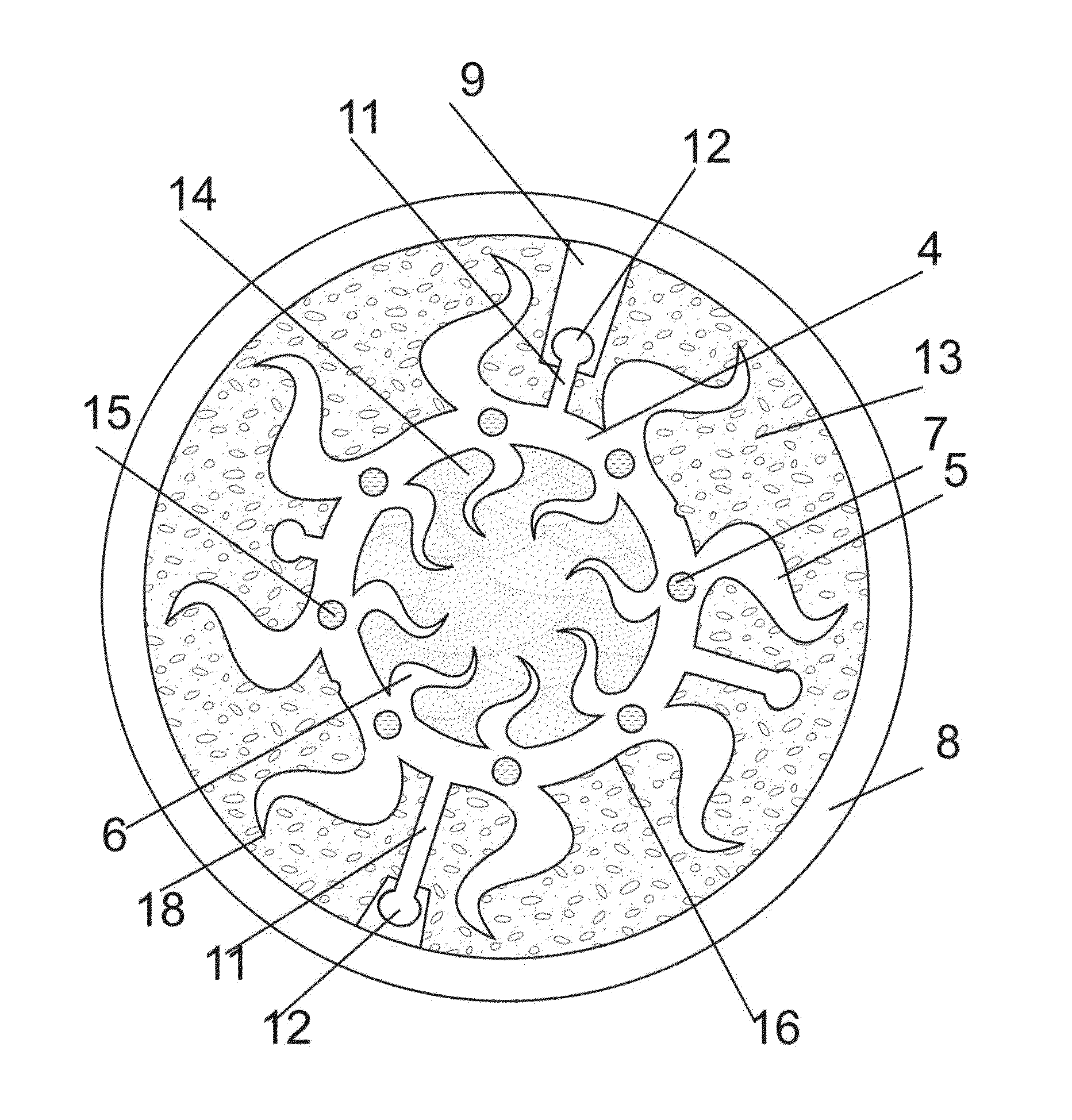

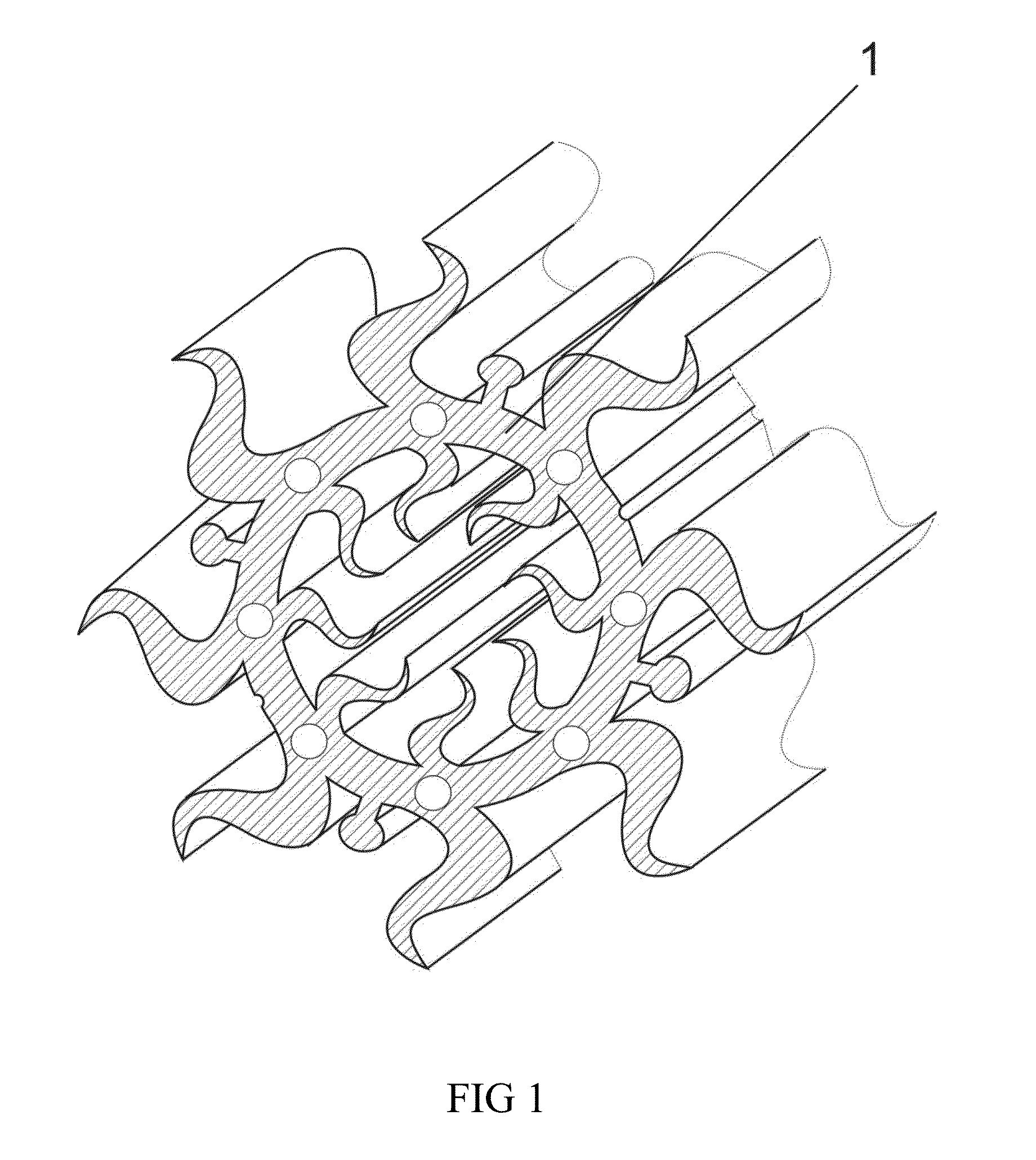

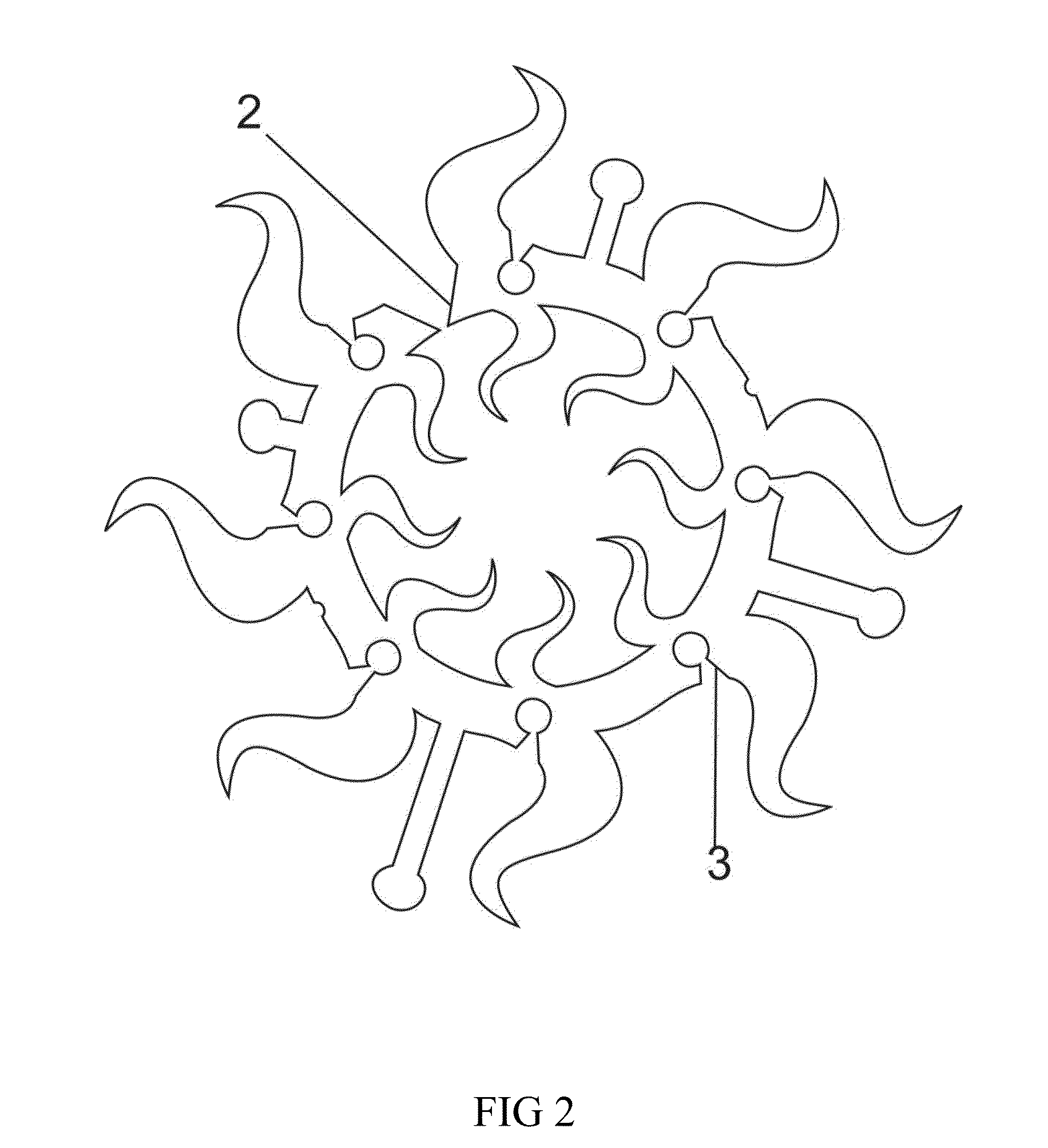

[0024]The heat exchanging device consists of one piece 1 (FIG. 1). It is made by extrusion. The device has technological gaps 2 and 3, which are subsequently welded (FIG. 2). The heat exchanging device is made as a tubular body 4 with the external 5 and internal 6 radial branches. The geometry of the radial external 5 and internal 6 branches is determined by calculation, depending of the thermal balance of the specified device. The tubular body in a circumferential direction has identical longitudinal round holes 7 (FIG. 3). The device is designed to be mounted inside the case 8 and is fixed inside the case 8 in the protruding parts 9 with apertures 10 by means of a fastener located on the external surface of the tubular body. The fastener is made in the form of projections 11 at the edges 12 (FIG. 4). The fastener can be of different length and is made in various places on the external surface of the tubular body (FIG. 11). The number of fasteners is chosen by calculation and depen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com