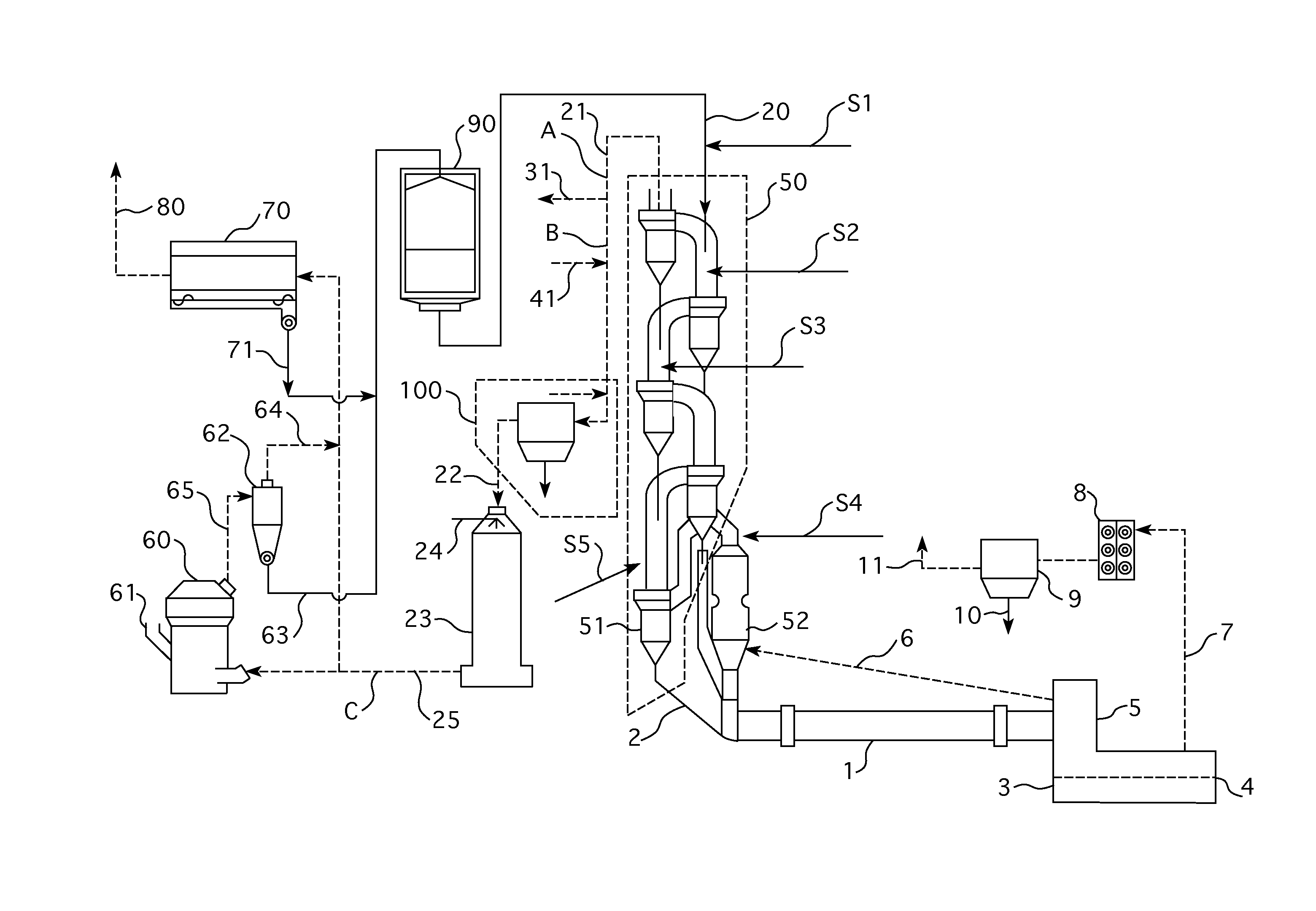

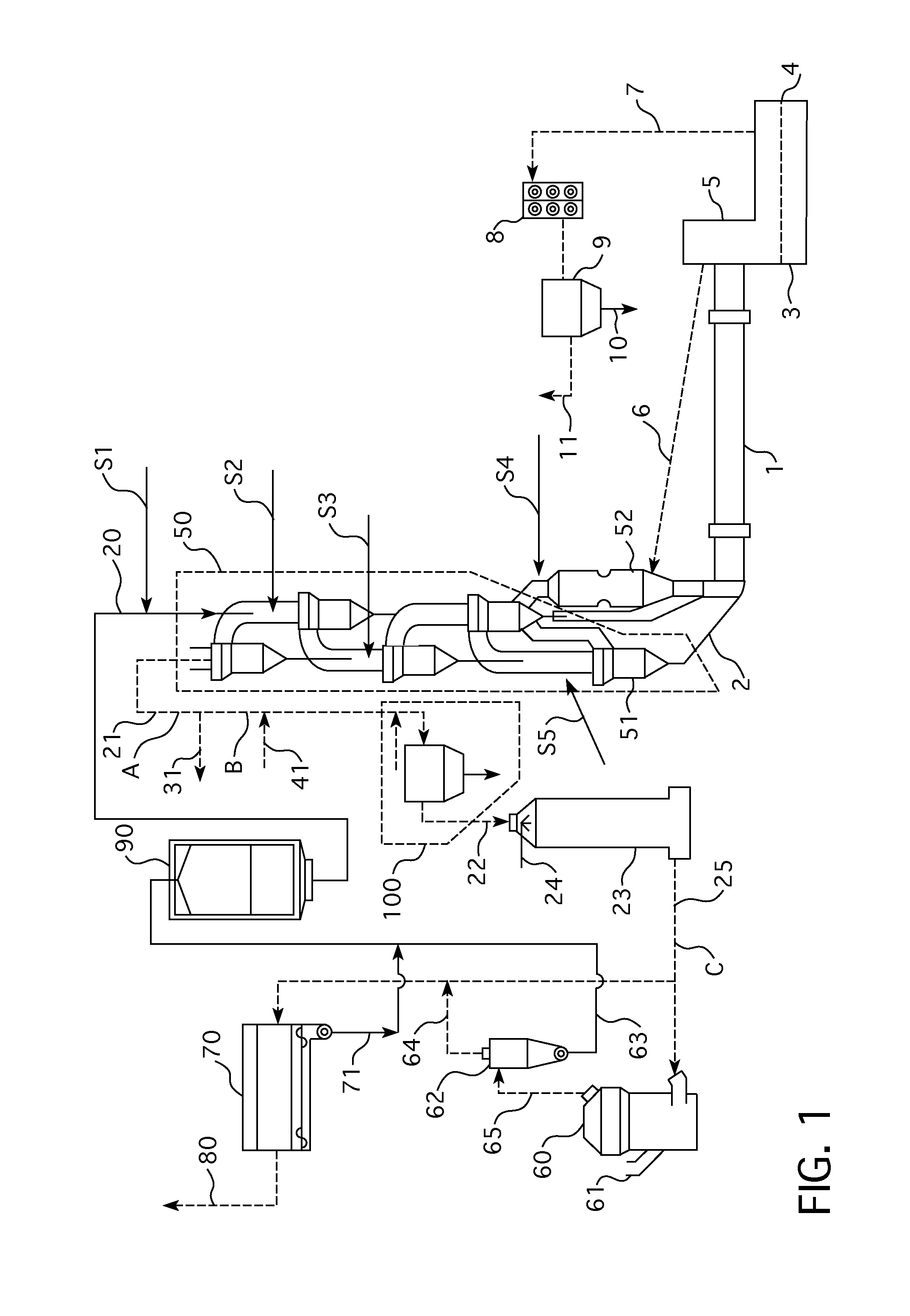

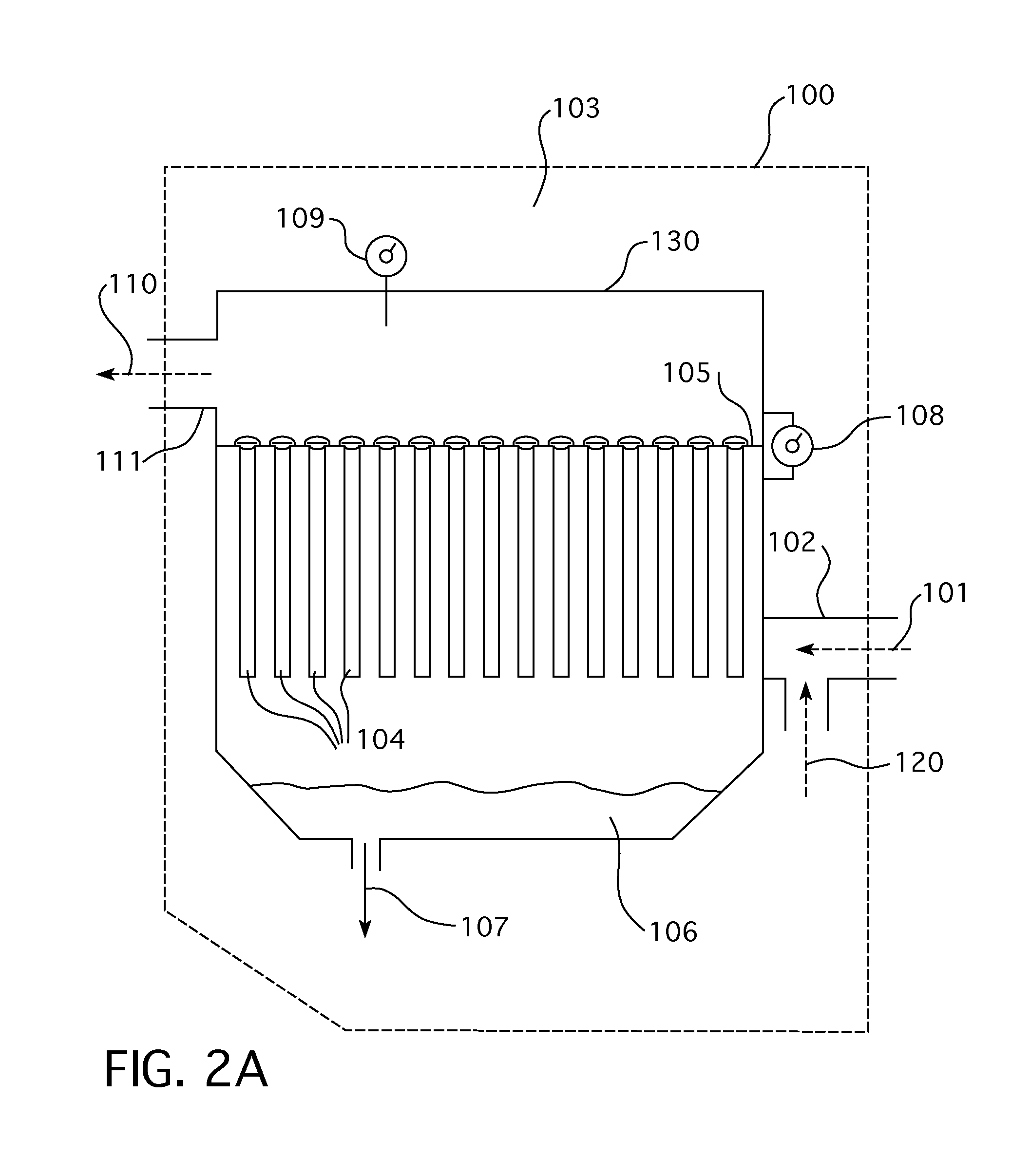

Pollution control system for kiln exhaust

a technology of pollution control system and kiln exhaust, which is applied in the direction of lighting and heating apparatus, separation processes, furnaces, etc., can solve the problems of reducing the thermal efficiency of the unit, reducing the level of emissions currently experienced, and prohibitively expensive existing emissions control technologies in other applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]Although the invention is particularly directed to the reduction in emissions of organic compound emissions, the present invention also applies to the removal of other products of incomplete or partial combustion such as carbon monoxide, condensable VOC's, nitrogen oxides, and dioxin / furans that contaminate manufacturing processes. Many of the organic compounds that this invention is directed towards fall under numerous overlapping categories of compounds, such as Total Organic Carbon (TOC), Total Hydrocarbons (THC), and Volatile Organic Compounds (VOC), and this invention is broadly aimed to the various compounds which are classified under these general categories. Also, while emphasis is placed on a cement manufacturing process, the present invention is applicable to other minerals and kiln manufacturing processes, such as lime manufacturing processes and other industrial processes where very high starting emission levels of these contaminate compounds can not be sufficientl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com