Inverted cylindrical magnetron (ICM) system and methods of use

a technology of inverted cylindrical magnetron and magnetron, applied in the direction of electrolysis components, vacuum evaporation coatings, coatings, etc., can solve the problems of reducing the efficiency of the magnetic field, increasing the fabrication cost, and affecting the effect of the magnetic field line virtual anode formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The foregoing and other features and advantages of the invention are apparent from the following detailed description of exemplary embodiments, read in conjunction with the accompanying drawings. The detailed description and drawings are merely illustrative of the invention rather than limiting, the scope of the invention being defined by the appended claims and equivalents thereof.

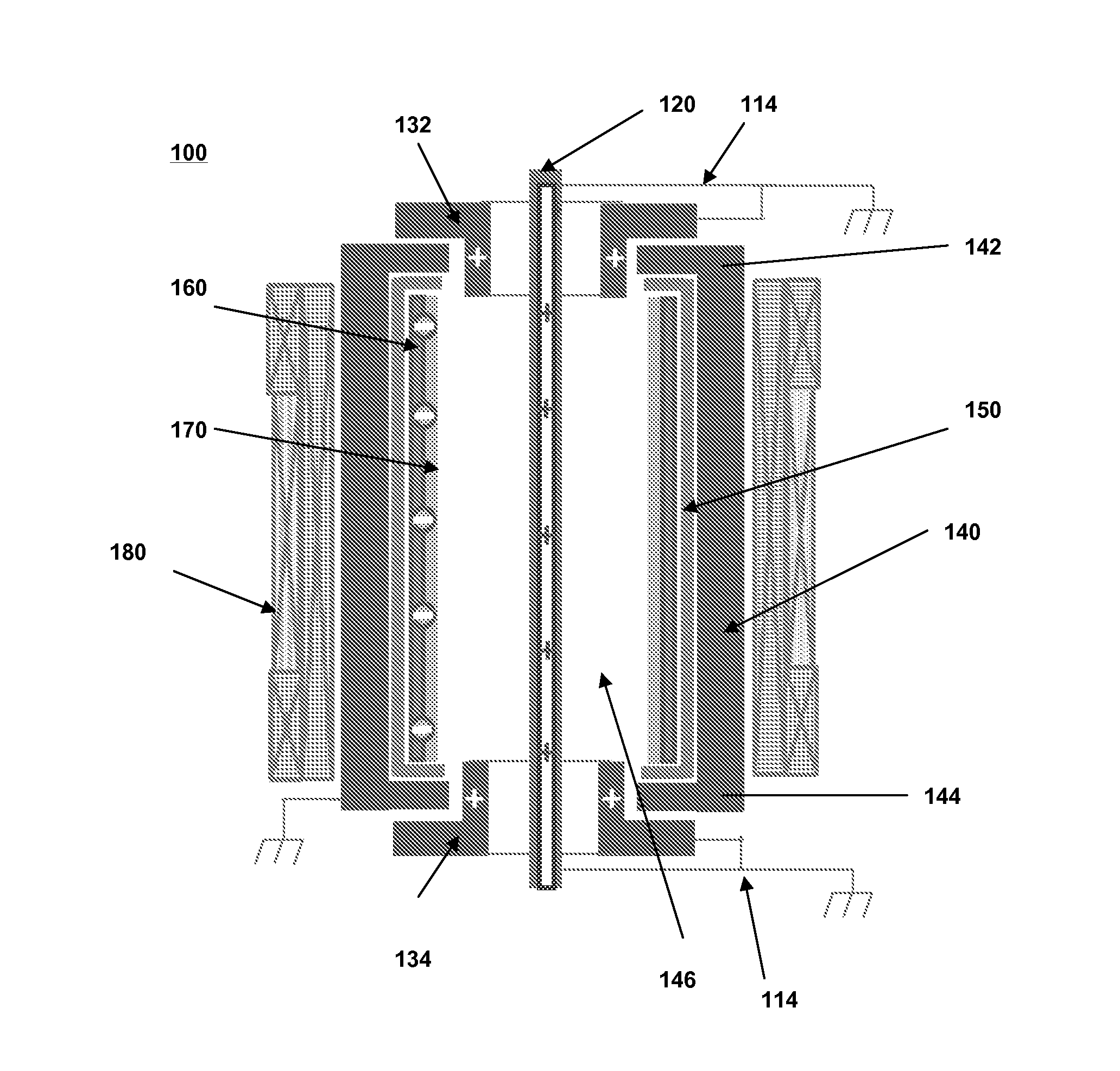

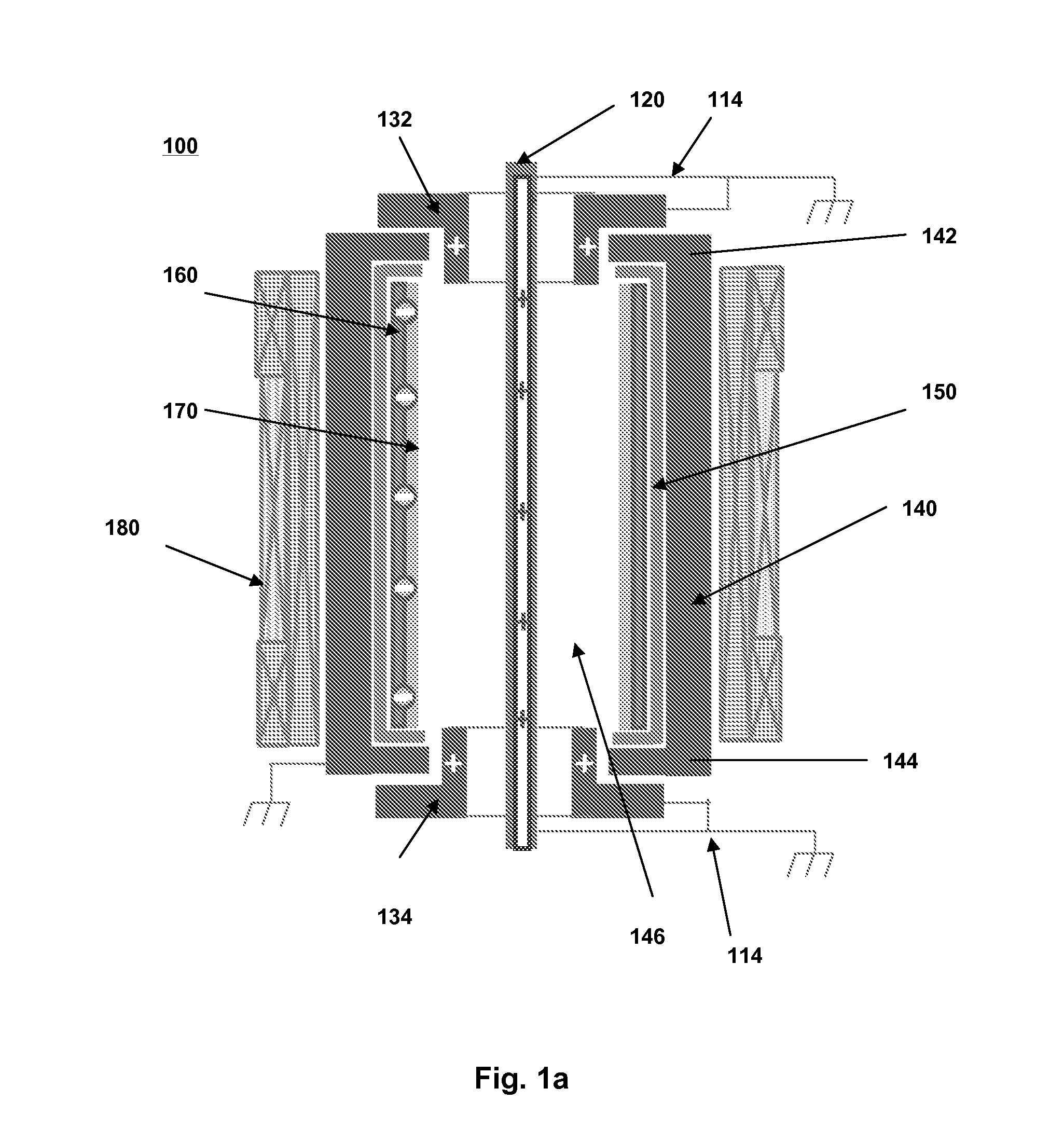

[0024]Generally speaking, the inverted cylindrical magnetron source (ICM), also known as hollow cathode magnetron source, and associated sputter deposition system are deployed for high throughput and precisely controlled uniform deposition of high purity cylindrical metallic thin films.

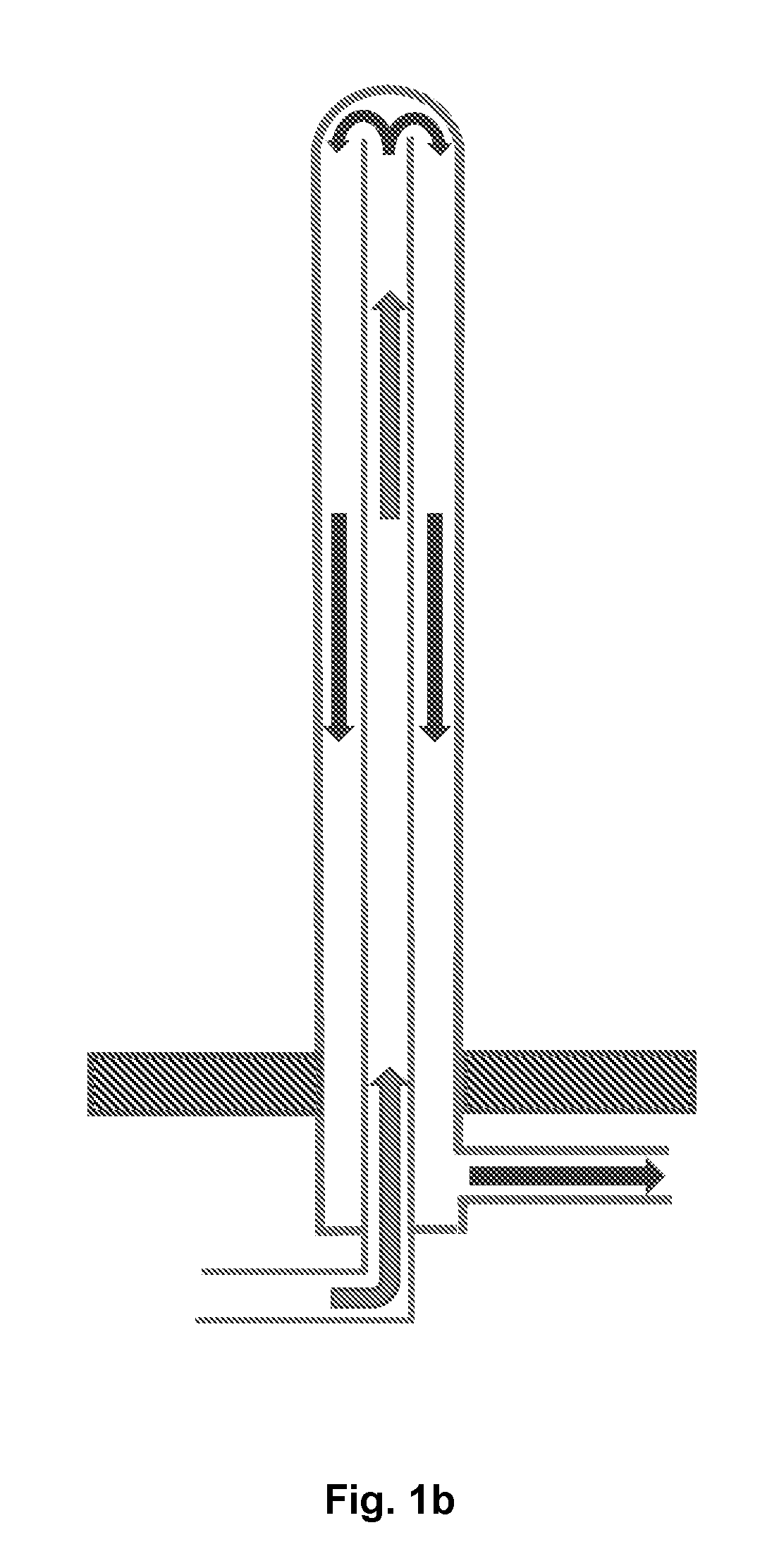

[0025]As shown in FIG. 1a, an inverted cylindrical magnetron (ICM) source 100 generally comprises a co-axial central anode 120 concentrically located within a first annular end anode 132 and a second annular end anode 134, which is the core of a cylindrical process chamber 320 including a top end 142 and a bottom end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com