Pumping mechanism, distributing valve thereof and concrete pumping machine

a technology of pumping mechanism and distributing valve, which is applied in the direction of machines/engines, positive displacement liquid engines, transportation and packaging, etc., can solve the problems of increasing the energy consumption lowering the driving etc., to reduce the driving force, increase the pumping pressure and improve the sealing performance of the distributing valv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The present invention will be detailed hereinafter taken in combination with the drawings, and the following description are just demonstrative and explanatory, and shall not be understood as limitations in any way on the scope of protection of the present invention.

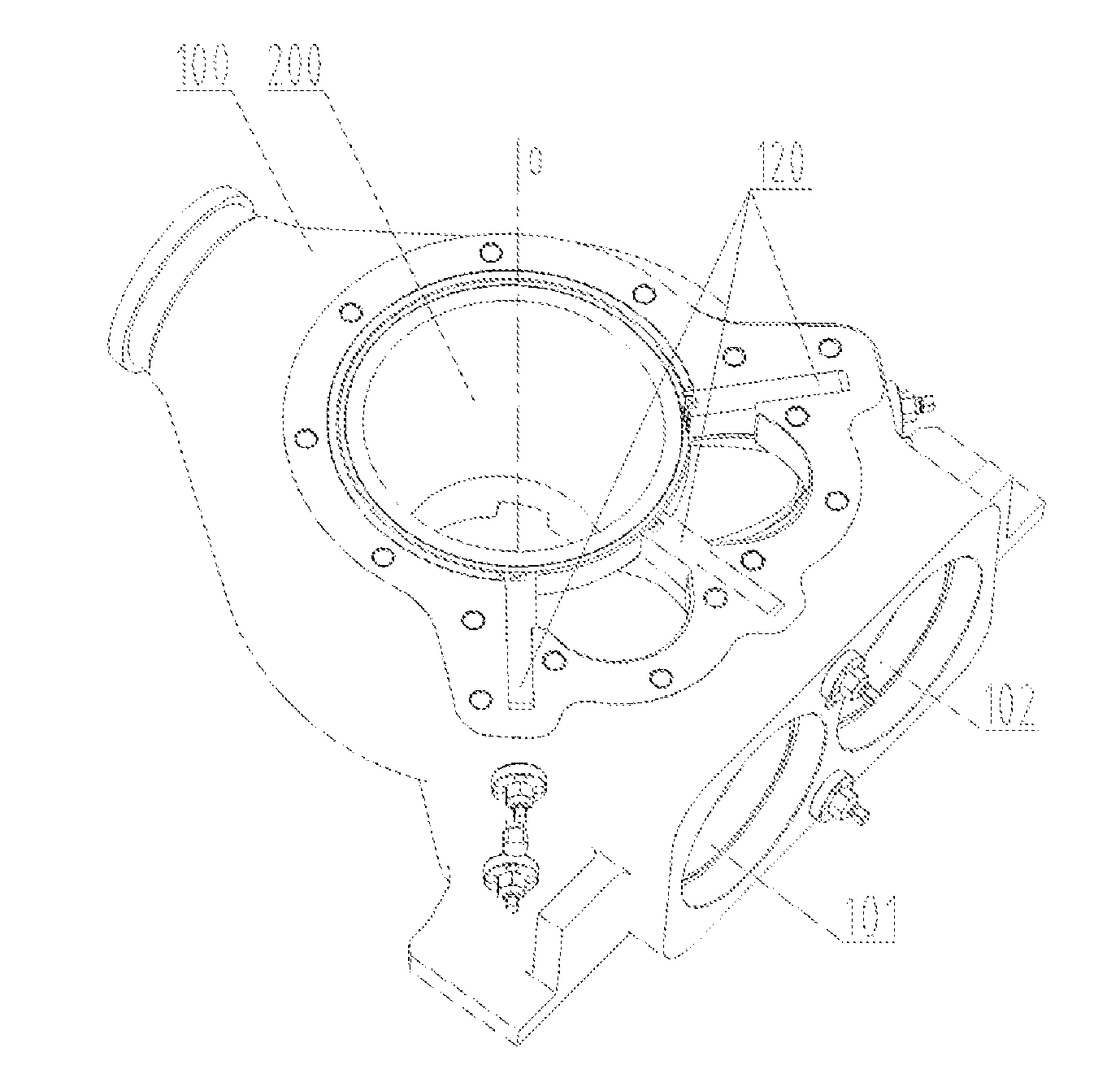

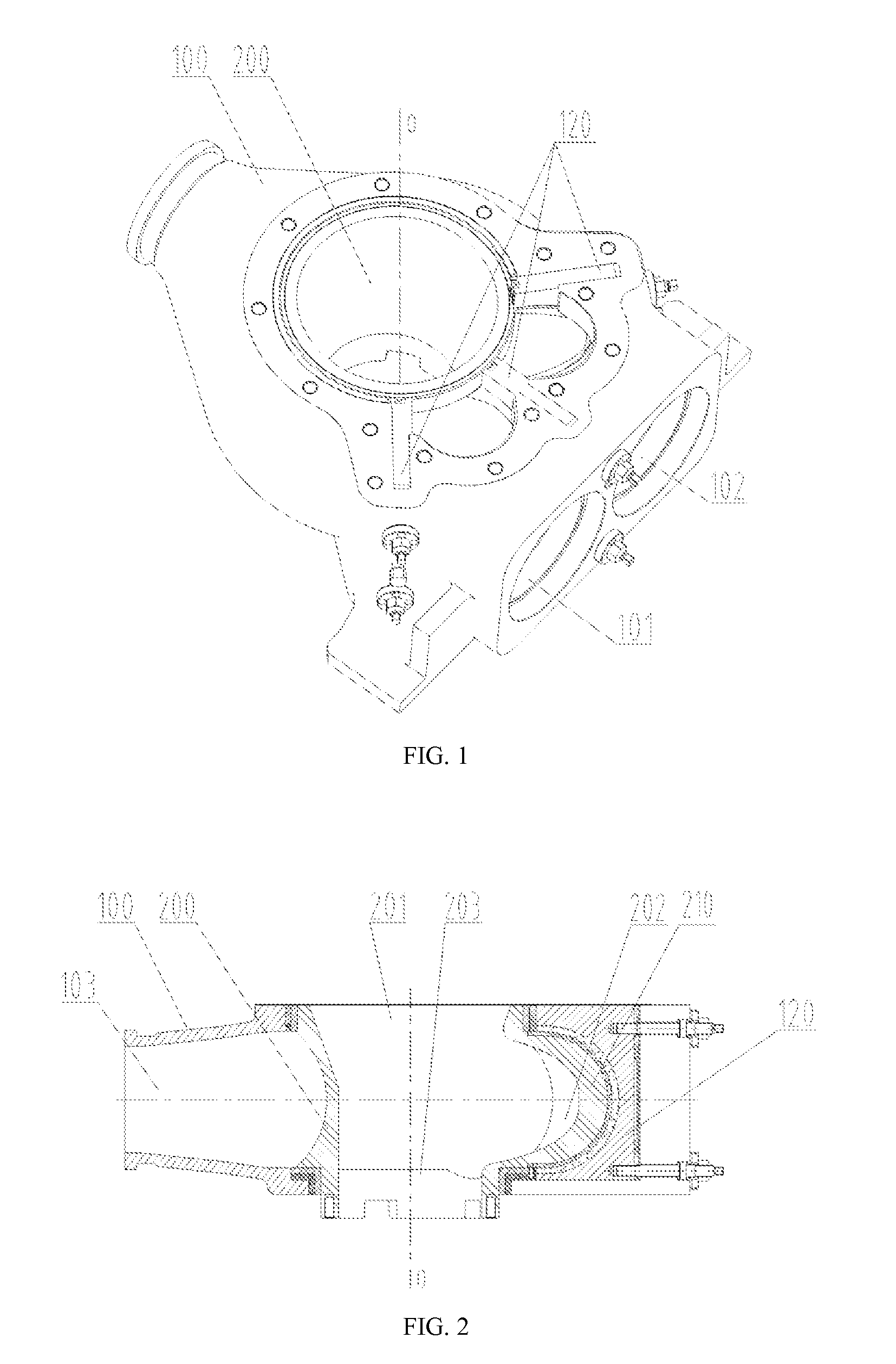

[0036]Referring to FIGS. 1-3, FIG. 1 is a schematic diagram of the three-dimensional structure of the distributing valve provided by the present invention; FIG. 2 is a schematic diagram of the sectional structure of the distributing valve shown in FIG. 1; and FIG. 3 is a schematic diagram of the three-dimensional assembling structure of the distributing valve shown in FIG. 1.

[0037]The distributing valve of the pumping mechanism provided by the present invention comprises a valve casing 100 and a valve core 200. In combination with FIGS. 1 and 3, the valve casing 100 is in a case-shape structure and is formed with a pumping chamber therein. The valve casing 100 comprises a discharge hole 103 throughout the casing wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com