Aluminum-magnesium alloy and method of producing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Technical Problem

[0006]The present invention provides an aluminum (Al)-magnesium (Mg) alloy capable of minimizing the use of a protective gas, having excellent mechanical properties and a high processability, and having a high the content of Mg, and a method of producing the same. However, the present invention is not limited thereto.

Technical Solution

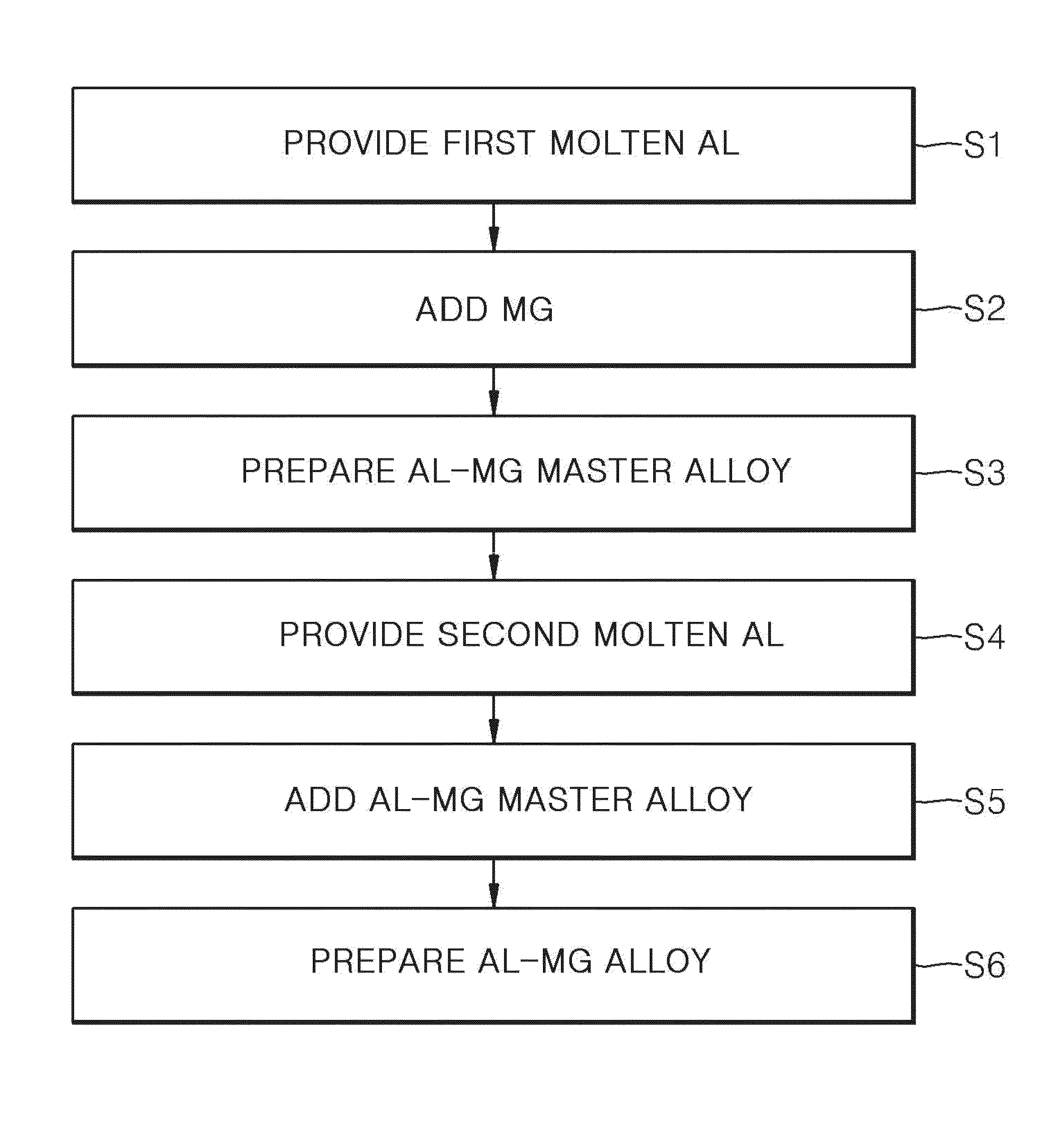

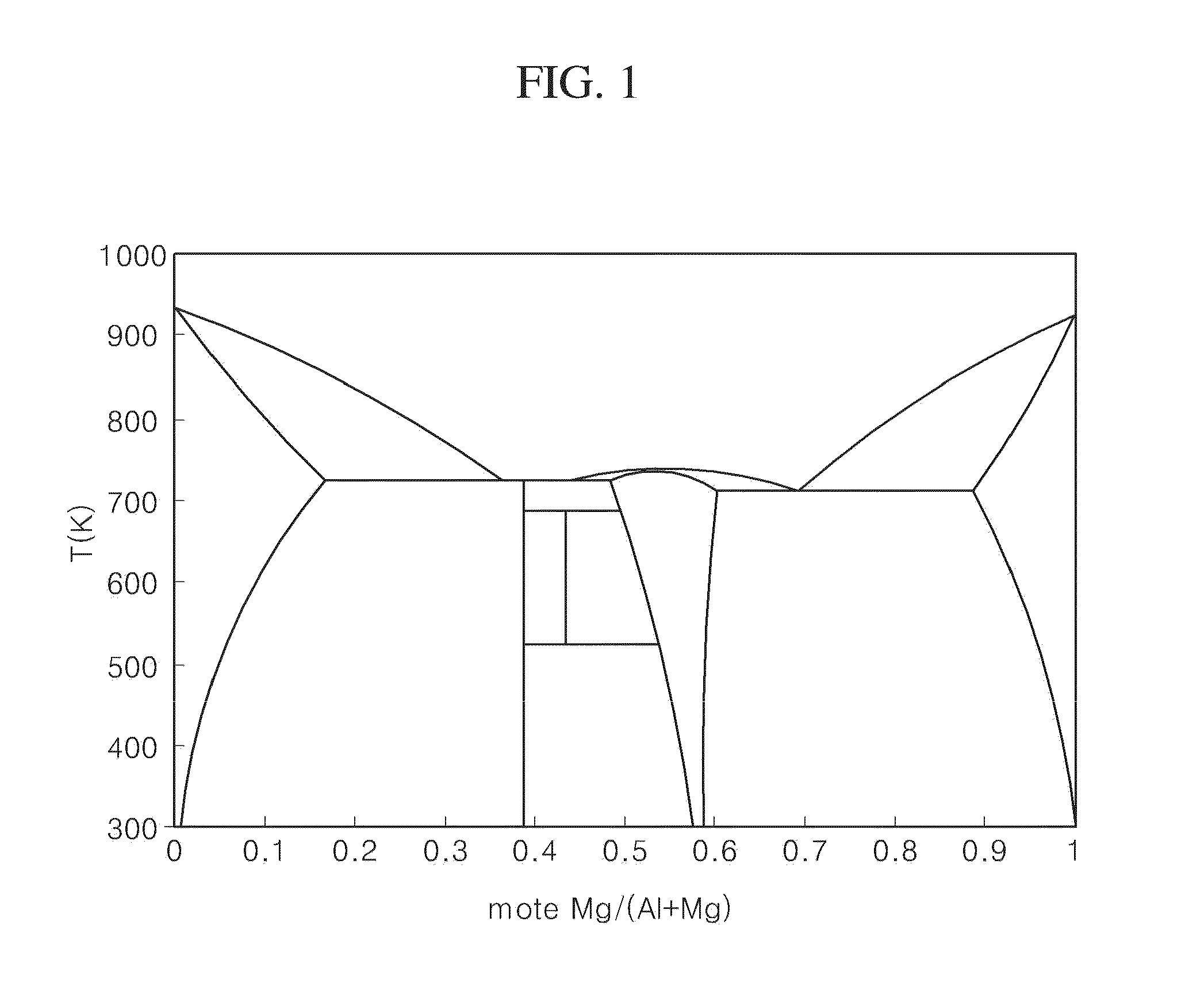

[0007]According to an aspect of the present invention, there is provided a method of producing an aluminum (Al)-magnesium (Mg) alloy. Mg is added into first molten Al. An Al—Mg master alloy having a first Mg content is prepared by casting the first molten Al in which Mg is added. The Al—Mg master alloy is added into second molten Al. An Al—Mg alloy having a second Mg content less than the first Mg content is casted by casting the second molten Al.

[0008]A holding time for melting the Al—Mg master alloy in the adding of the Al—Mg master alloy may be less than the holding time for melting the Mg in the adding of the Mg.

[0009]A melting poi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com