Tower and wind turbine generator having the same

a technology of wind turbine generator and turbine, which is applied in the direction of buildings, buildings, buildings, etc., can solve the problems of increasing the outer diameter of the tower, reducing the service life of the tower, so as to reduce the manufacturing and construction costs, reduce the displacement, and improve the yield strength of the flange junction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

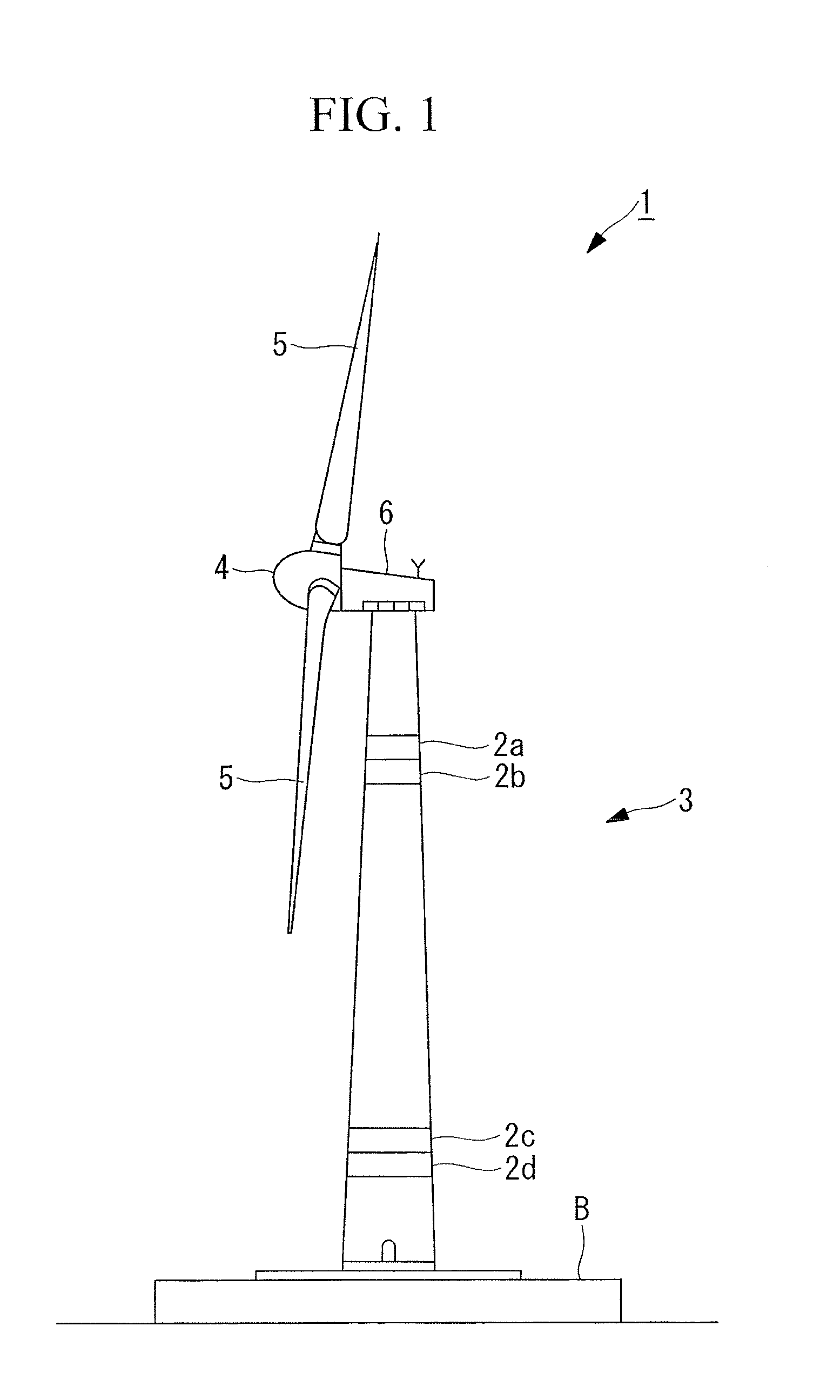

[0056]As shown in FIG. 1, a wind turbine generator 1 includes a tower 3 vertically installed on a base B, a nacelle 6 installed at an upper end of the tower 3, and a rotor head 4 provided at the nacelle 6 so as to be rotatable about a substantially horizontal axis. A plurality of (for example, three) wind turbine rotary blades 5 are radially attached to the rotor head 4 around the rotation axis of the rotor head 4. Thereby the force of the wind on the wind turbine rotary blades 5 from the direction of the rotation axis of the rotor head 4 is converted into power for rotating the rotor head 4 about the rotation axis.

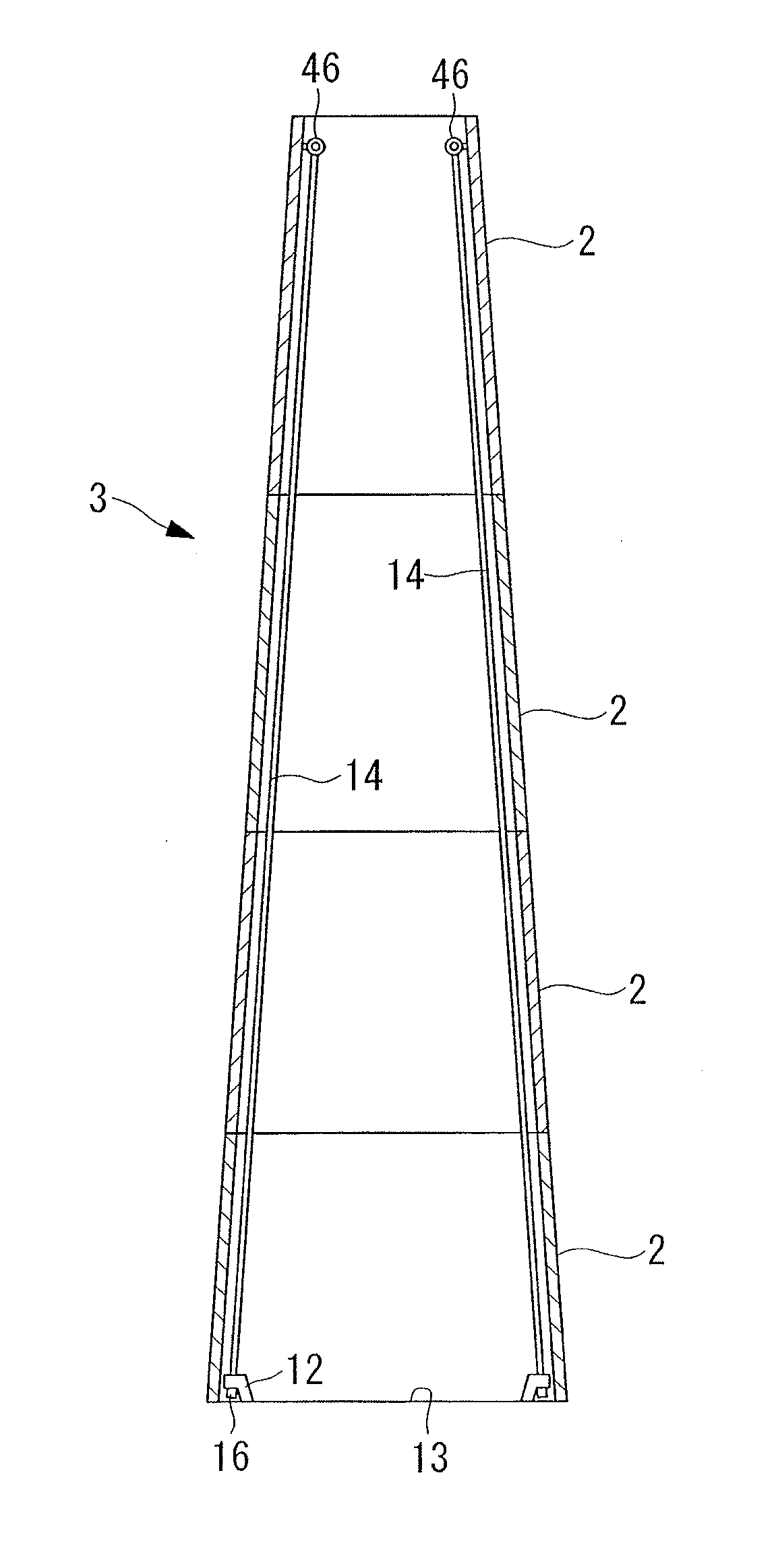

[0057]In the first embodiment of the present invention, the tower 3 is configured by stacking and joining a plurality of tower sections 2 to each other in the vertical direction, and is provided in the wind turbine generator 1.

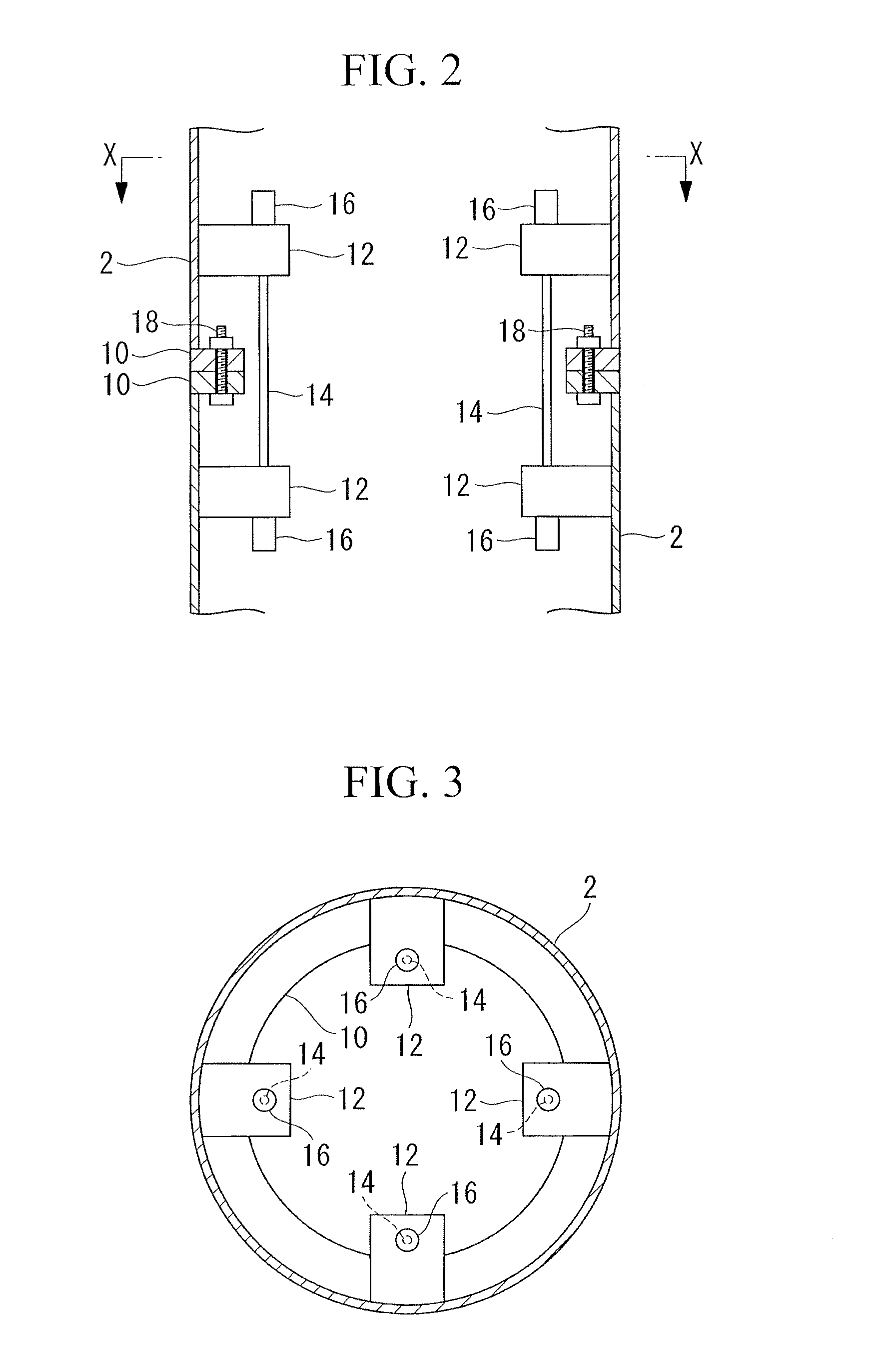

[0058]As shown in FIG. 2, a flange 10 is provided at an end of the tower section 2, and at a junction where the ends of the tower sections 2 are bu...

second embodiment

[0080]FIG. 7 shows a fixing bracket used in a tower in accordance with a second embodiment of the present invention. The same members as those in the above-mentioned embodiment are denoted by the same reference symbols and redundant description thereof is not repetitively provided.

[0081]In the present embodiment, the fixing bracket 12d has a groove 20 for inserting the wire rope 14 thereinto. The groove 20 extends substantially linearly outward in the radial direction (toward the left in FIG. 7) from a free end of the fixing bracket 12d (inner circumferential end in cross section of the tower; right end in FIG. 7), and terminates substantially at the center of the fixing bracket 12d. A width of the groove 20 is substantially constant in the extending direction and is larger than a diameter of the wire rope 14. However, the width of the groove 20 is smaller than a width of a socket base 16a serving as a base of the socket 16, and by provision of the groove 20, the socket 16 is locked...

third embodiment

[0085]FIG. 9 shows a fixing bracket used in a tower in accordance with a third embodiment of the present invention. The same members as those in the above-mentioned embodiments are denoted by the same reference symbols and redundant description thereof is not repetitively provided.

[0086]In the present embodiment, the socket 16 is rectangular in a plan view, specifically, oblong. A through hole 22 for inserting the wire rope 14 thereinto is formed in the fixing bracket 12e. The through hole 22 is oblong like the socket 16 and has a dimension that enables insertion of the socket 16.

[0087]A concave part 22a dented in the plate thickness direction is provided in an upper surface of the fixing bracket 12e. The concave part 22a is in an oblong shape that is slightly larger than the socket 16 in a plan view, and the socket 16 is partially or entirely fitted into the concave part 22a. A long side of the oblong concave part 22a is shifted from a long side of the oblong through hole 22 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com