Efficient production line for aerosol cans

a production line and aerosol can technology, applied in the field of production lines, can solve the problems of limited production speed of the production line section that is connected upstream or downstream, and reduce the effect of productivity, and achieve the effect of reducing the production speed of the upstream production line section and the downstream production line section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

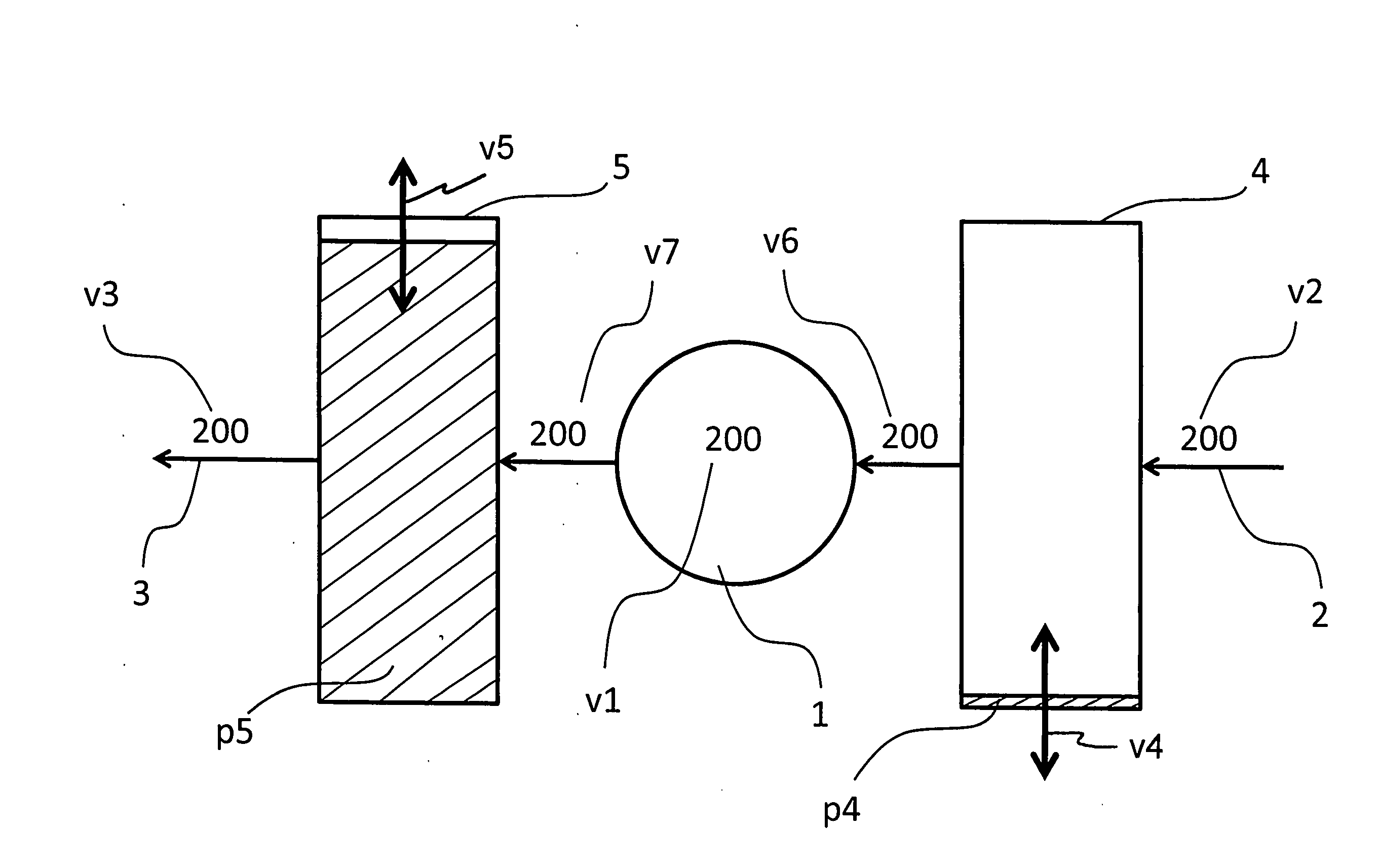

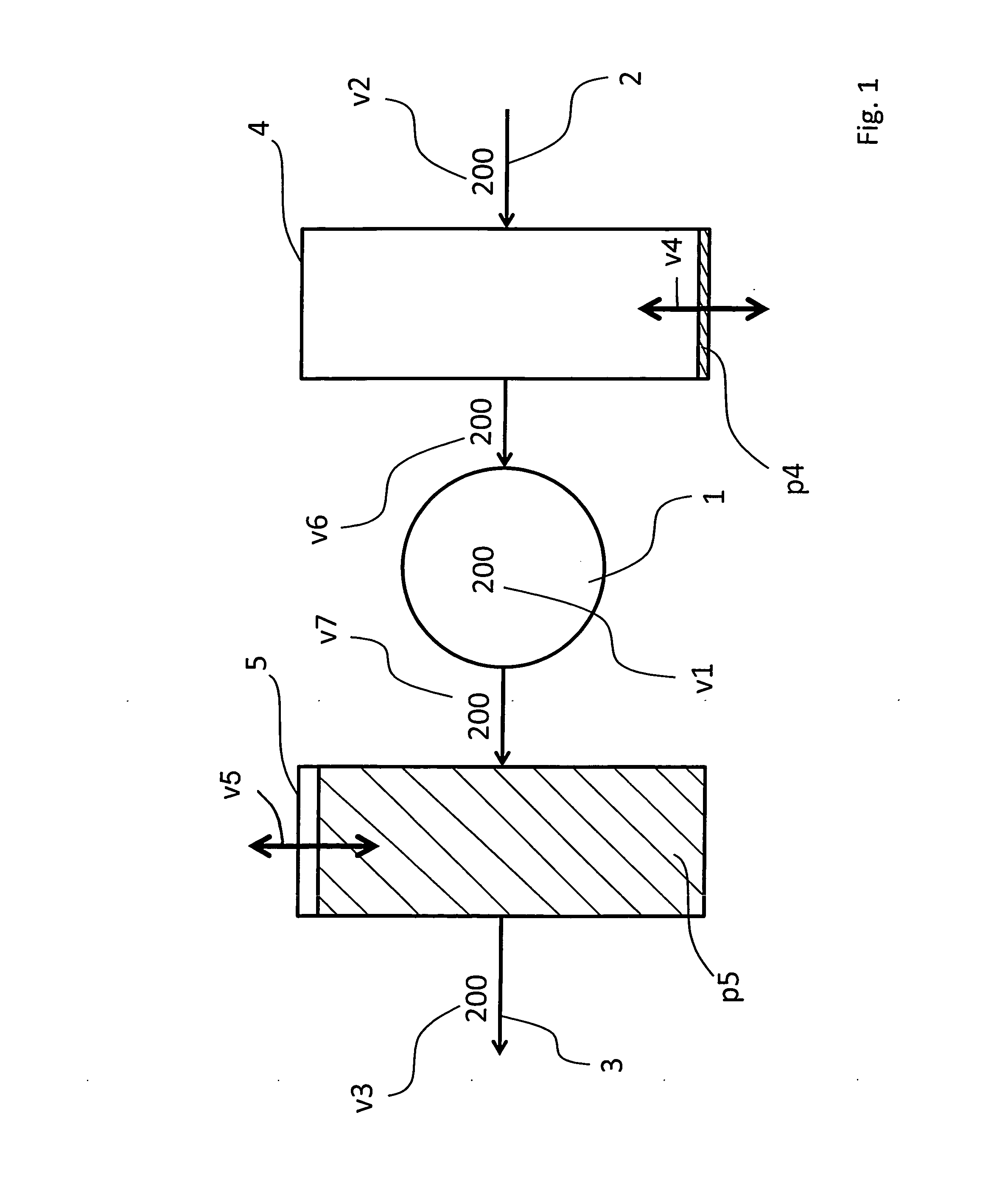

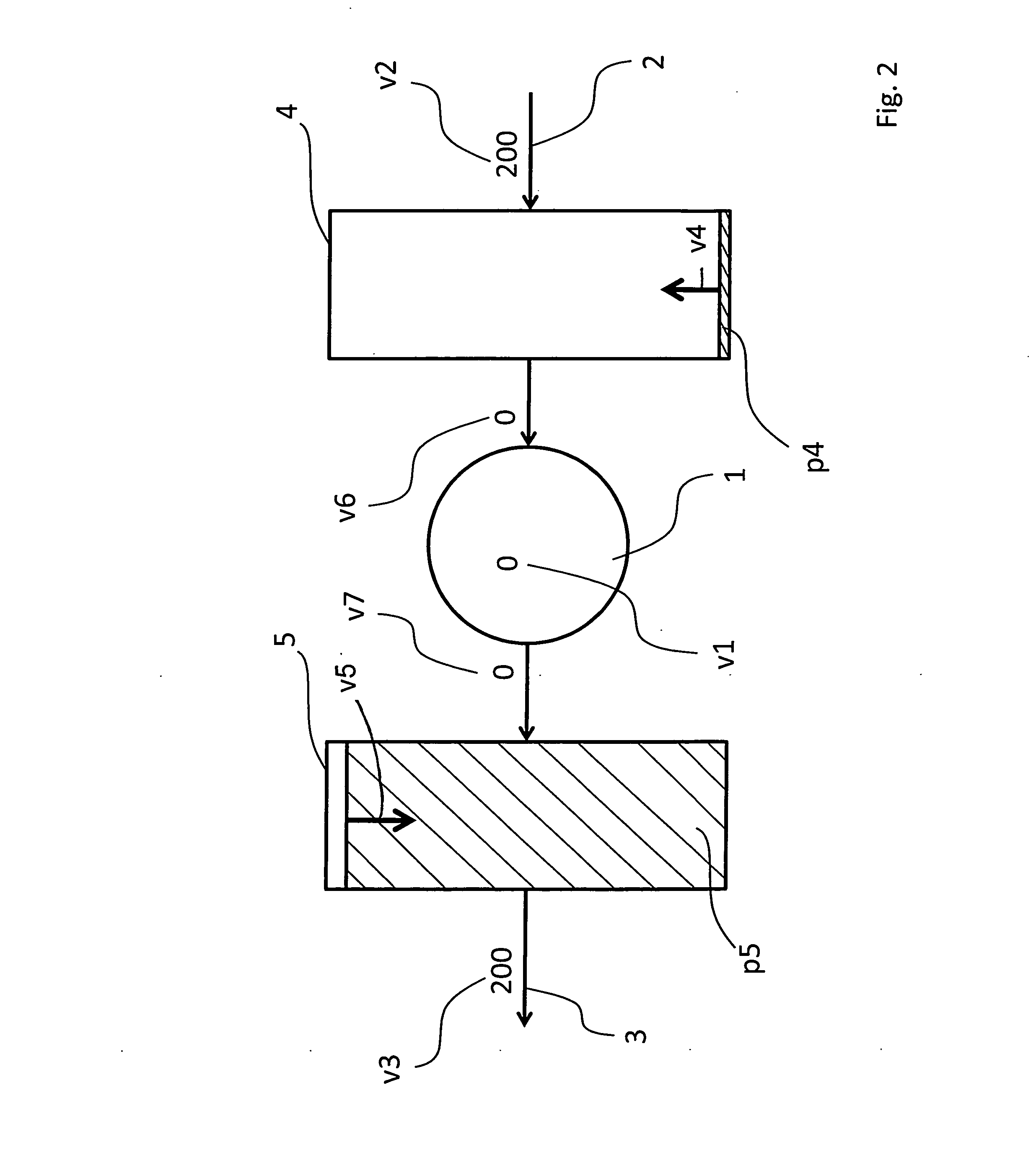

[0038]An assembly line 100 in FIGS. 1 through 8 includes a temporarily discontinuously operating processing station 1 with a production speed v1. The temporarily discontinuously operating processing station 1 has a production line section 2 connected upstream and a production line section 3 connected downstream. The production line section 2 operates with a production speed v2, the production line section 3 operates with a production speed v3.

[0039]Between the upstream production line section 2 and the temporarily discontinuously operating processing station 1, a first product buffer 4 with a buffer level p4 is arranged between the temporarily discontinuously operating processing station 1 and the downstream production line section 3 a second product buffer 5 with a buffer level p5 is arranged. A transfer of the products to be processed from the first product buffer 4 to the processing station 1 is provided with a transfer speed v6, a transfer of the process products from the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com