Polymer interlayers comprising epoxidized vegetable oil

a technology of polymer interlayers and vegetable oil, which is applied in the direction of synthetic resin layered products, transportation and packaging, chemistry apparatus and processes, etc., can solve the problems of common degree of edge delamination, delamination and bubbling from inefficient degassing, and may compromise the structural integrity of glass panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

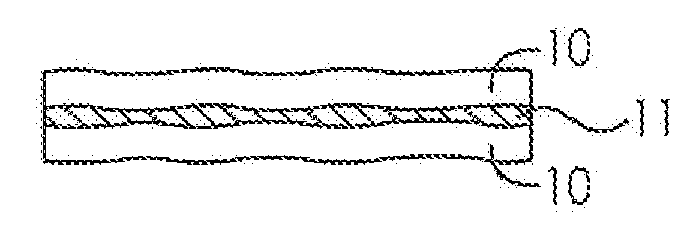

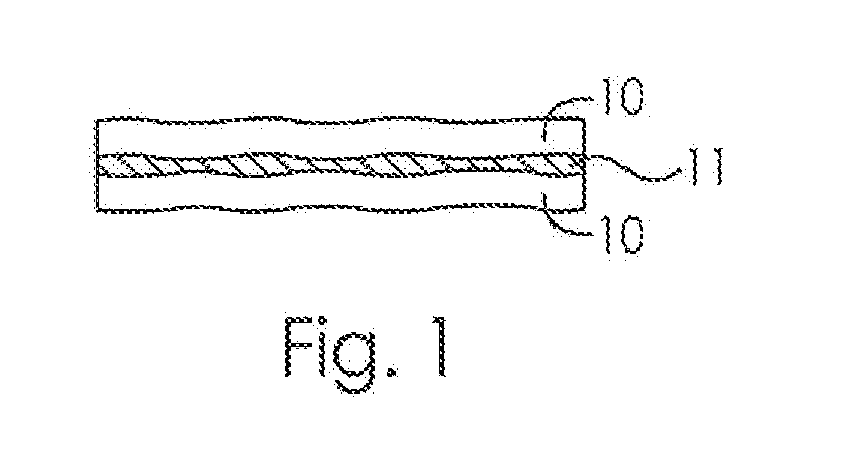

Image

Examples

example 1

[0084]

TABLE 2FlowSample(DF135)Tg (° C.)ExudationDI 10.242 mm30NoDI 20.232 mm30NoCI 10.211 mm30No

[0085]Table 2 demonstrates that the combination of conventional plasticizer with the epoxidized soybean oil consistently increases the flow of the interlayer without reducing the Tg, as compared to a conventional interlayer. A higher flow interlayer, as demonstrated above, can be particularly useful, for example, with tempered or mismatched glass, as the increase in flow allows the interlayer to fill the gaps that are inherent when the two substrates are assembled. It is equally important that the Tg of the higher flow interlayer is maintained at the same level as the conventional interlayer so that the mechanical strength of the interlayer can be maintained for the equivalent interlayer handling. Additionally, with the proper combination of the amount of conventional plasticizer and the amount of the epoxidized soybean oil, the interlayer does not experience exudation.

[0086]Additionally,...

example 2

[0087]

TABLE 3Sample% HazeDI 10.2DI 20.2CI 10.2

[0088]Table 3 depicts the results of the haze or optical clarity test. This table demonstrates that the laminates with the epoxidized soybean oil maintained a very low haze level. In fact, the clarity (haze level) of the laminates containing a polymer interlayer having the addition of the epoxidized soybean oil was comparable to the clarity or haze level of the conventional interlayer.

example 3

[0089]

TABLE 4Stack StickingPeel ForceSample(PLI)DI 36.68DI 48.10CI 210.31

[0090]Table 4 depicts the results of the stack sticking peel force test. In this test, the stacks are kept under the pressure of 69000 Pa at 40° C. for 24 hrs. The results shown in Table 4 demonstrate that the stack sticking peel force is favorably reduced with the addition of the epoxidized soybean oil when compared to conventional interlayer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com