Form fill compression seal and cut-off packaging system for compressible goods

a packaging system and form fill technology, applied in the field of form fill compression seal and cut-off packaging system for compressible goods, can solve the problems of more difficult accurate control of bags, and achieve the effects of improving the form fill compress and seal technology, improving manufacturing speed, and accurate bag handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

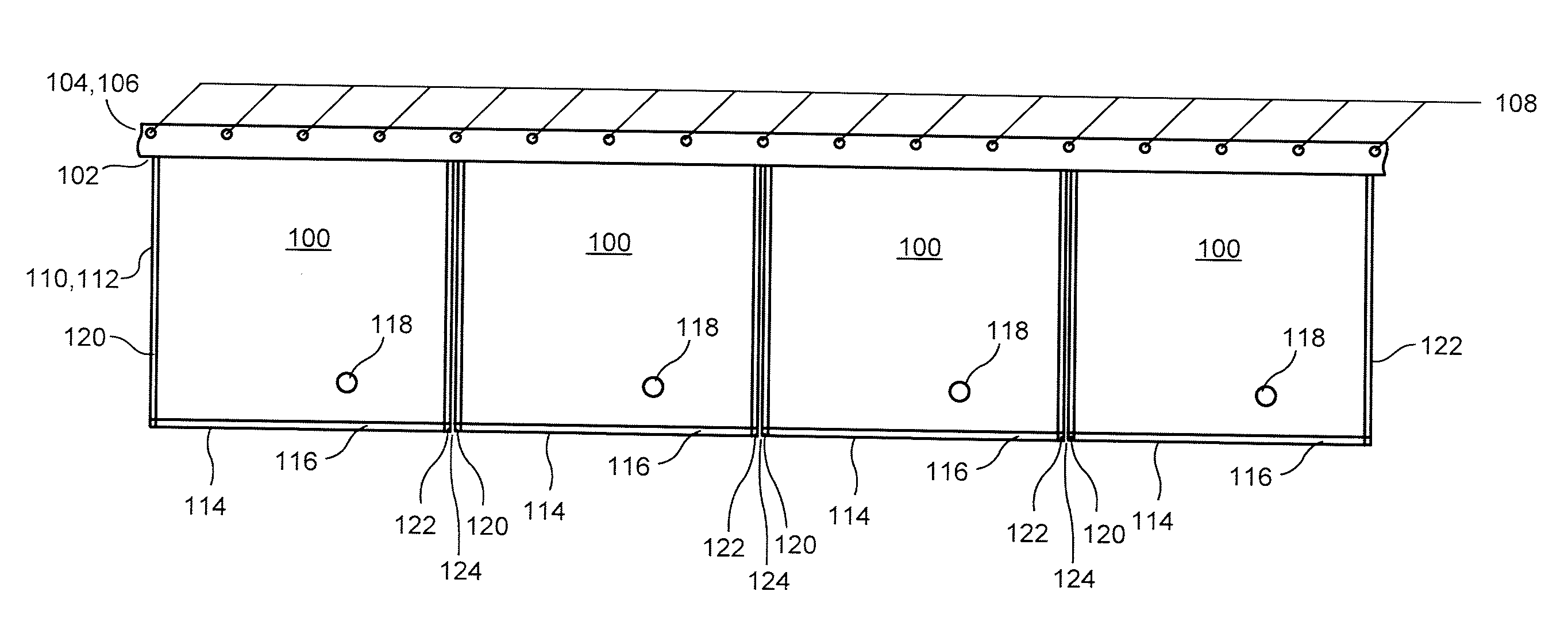

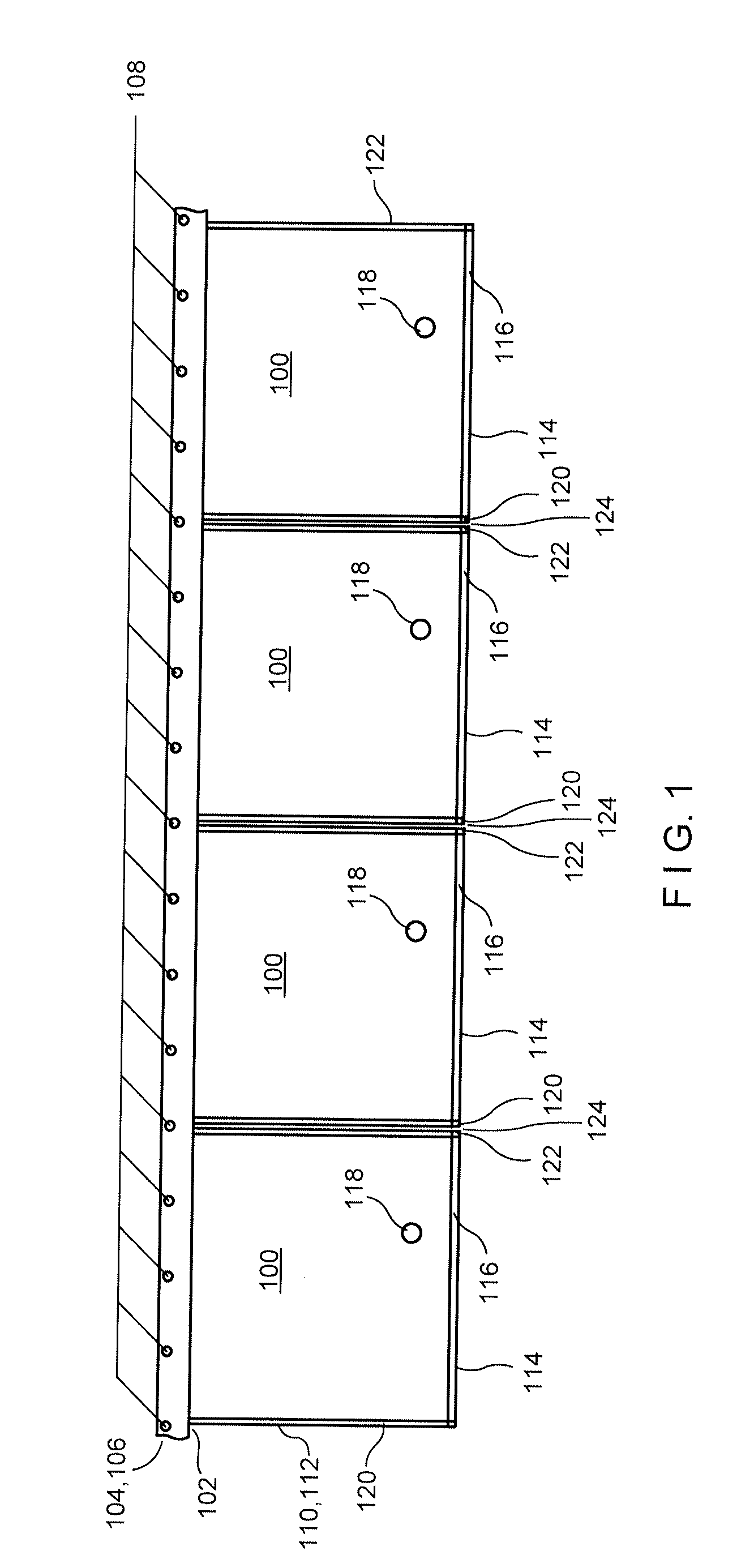

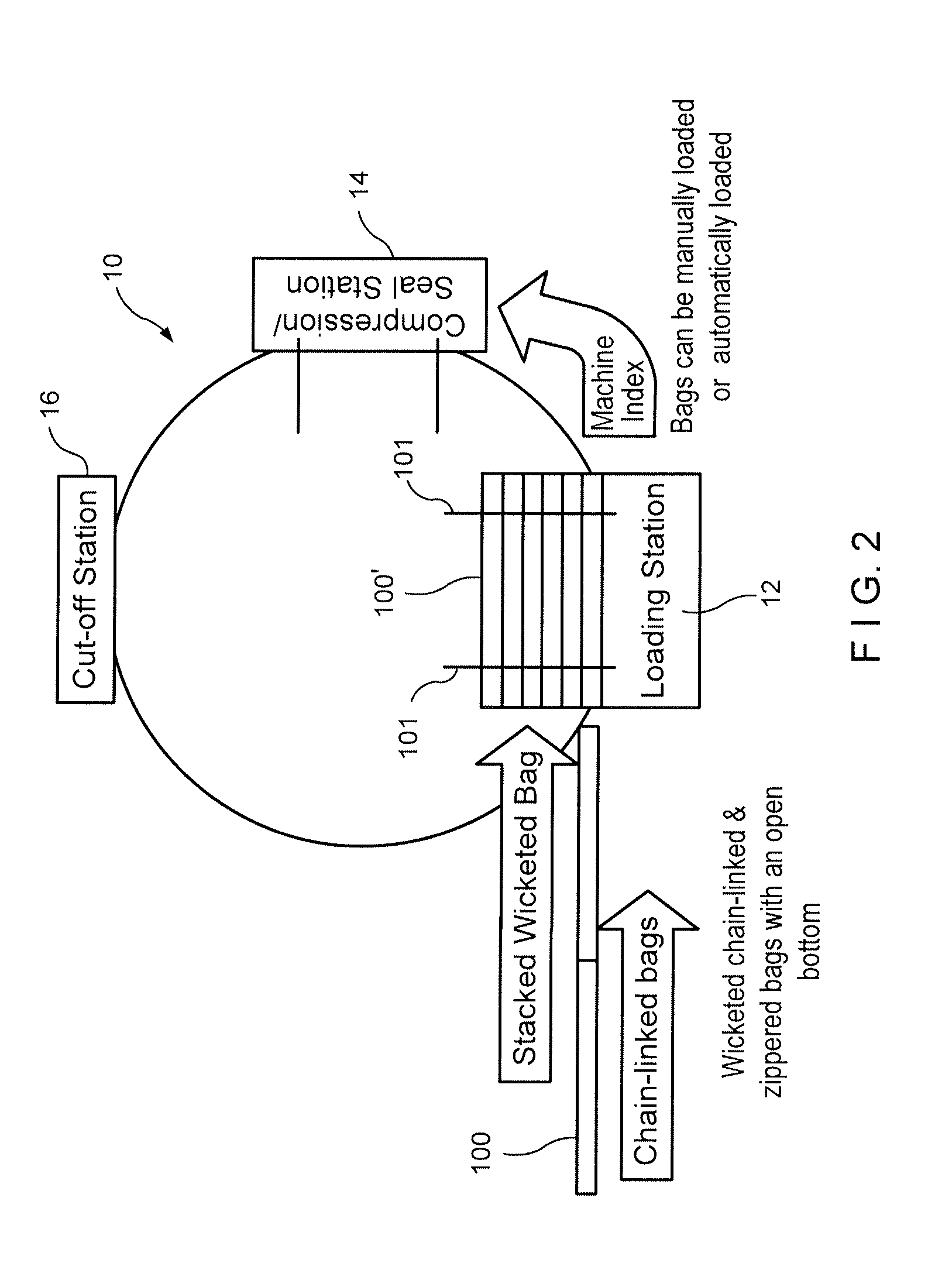

[0022]Referring now to the drawings in detail wherein like numerals indicate like elements throughout the several views, one sees that FIG. 1 is a side plan view of a concatenation of chain-linked bags 100 as used in embodiments of the present disclosure. The bags 100 are inverted so that open bottom 102 is presented as the uppermost part of the bag 100 in the orientation of FIG. 1. The open bottom 102 is formed between offset flanges 104, 106 (see FIG. 3) thereby presenting a path for filling or loading. Typically, one flange, illustrated here as flange 104 includes a series of spaced alignment apertures 108. The spacing of the apertures 108 corresponds to the spacing of the sprocket pin drive elements of the manufacturing apparatus (see subsequent figures). Front and rear polymeric walls 110, 112 extend from the flanges 104, 106 to form the bags 100, which a storage space formed therebetween. The top 114 of the bags 100, configured at the lowermost portion of the bags in the illus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com