Electric power device with integrated cooling system for controlling tools

a technology of electric power devices and control tools, which is applied in the direction of power-driven tools, grinding machines, grinding machine components, etc., can solve the problems of permanent damage, large motor parts, and long arm sanders, so as to prevent any risk of motor damage by overheating and not take up a lot of spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

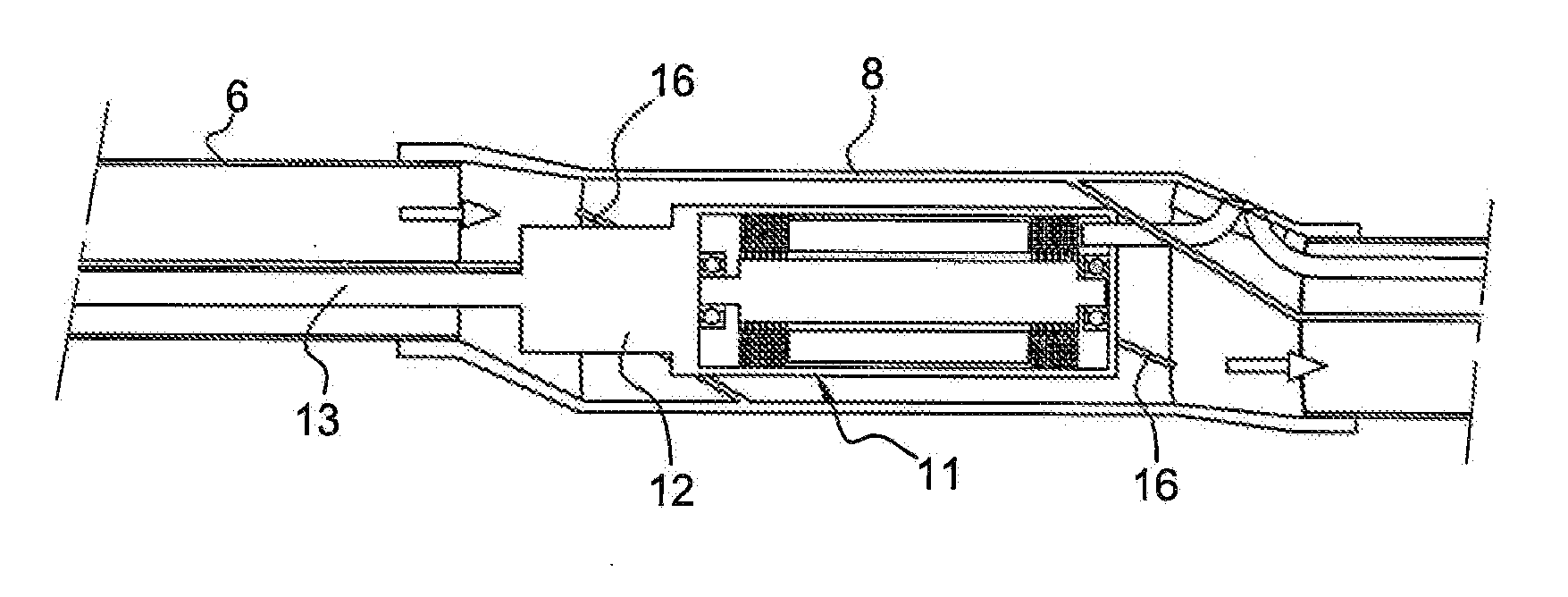

[0032]In the interests of clarity, in the remainder of the description, the same elements have been denoted using the same reference numbers in the various figures. Moreover, the various cross-section views are not drawn to scale.

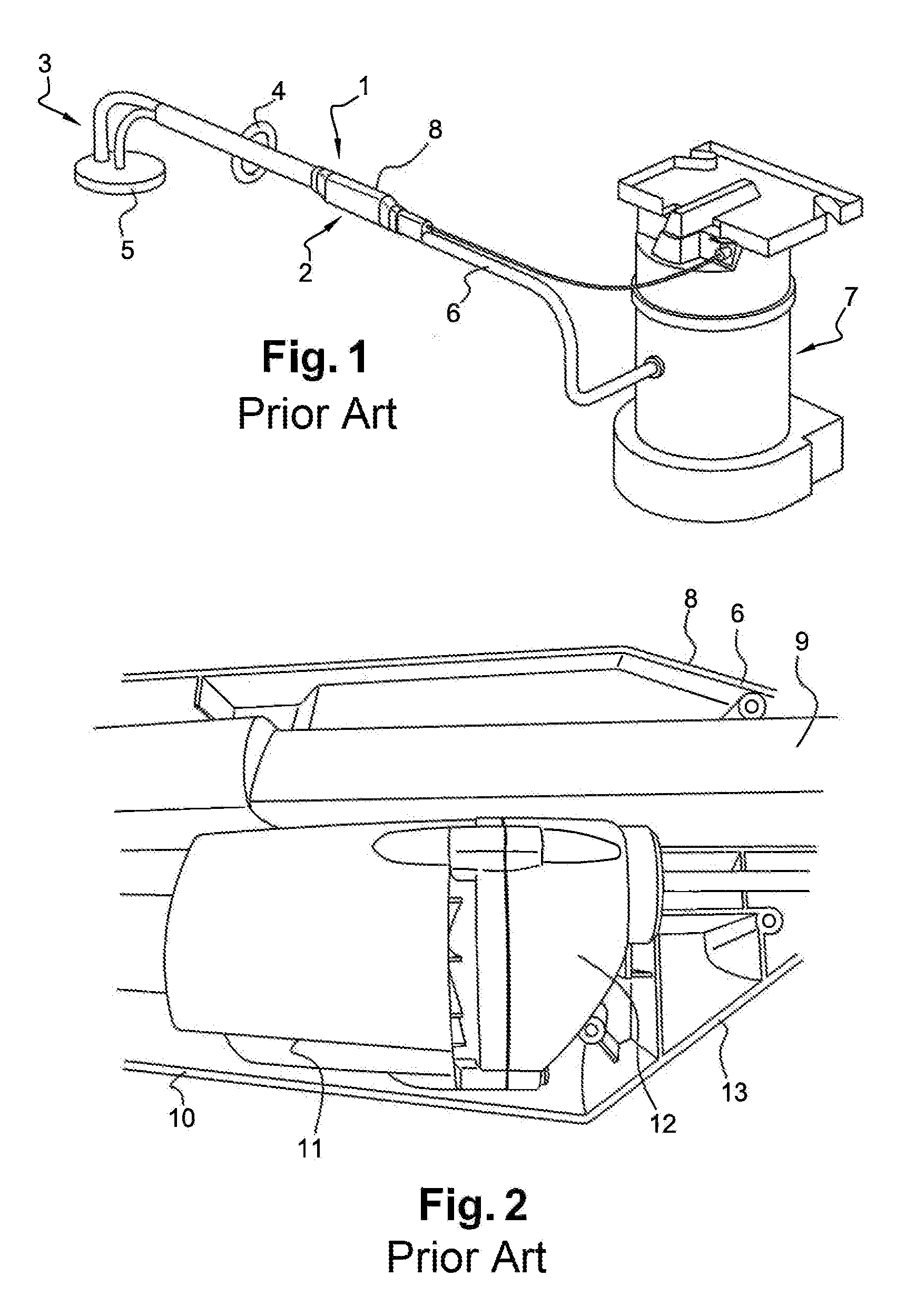

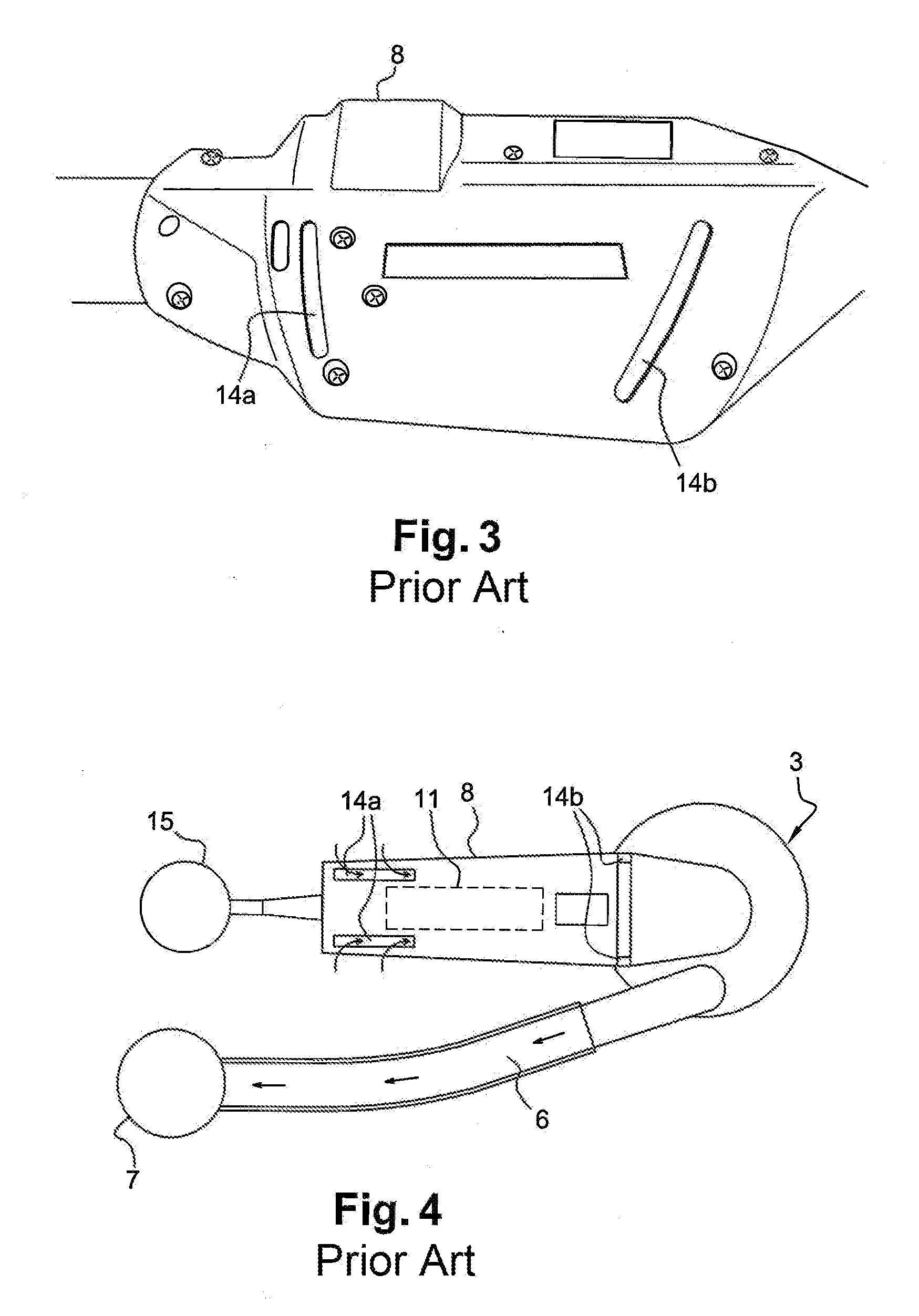

[0033]The long arm sander according to the invention comprises in the same way as prior art sanders, as shown in FIG. 1, a grip and carrying arm (1) to which is fitted a motor part (2) in the median portion thereof, an active head part (3) at the free end thereof and a grip handle (4) between the motor part (2) and the active head (3). The active head part (3) is in the shape of a curved neck and accommodates at the end thereof a sanding grind wheel (5).

[0034]Said long arm sander also comprises a suction pipe (6) for the waste produced by the sanding operation, such as dust for example, said suction pipe (6) passing through the grip arm, a first end leading to the active head (3) and the opposite end being connected to a suction device (7) for collecting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com