Furthermore, conventionally there are various methods of folding the tissue paper such as a one time folding method or a two time folding method, and the size of each folded side of the tissue paper and the position of the folded line is not always uniform.

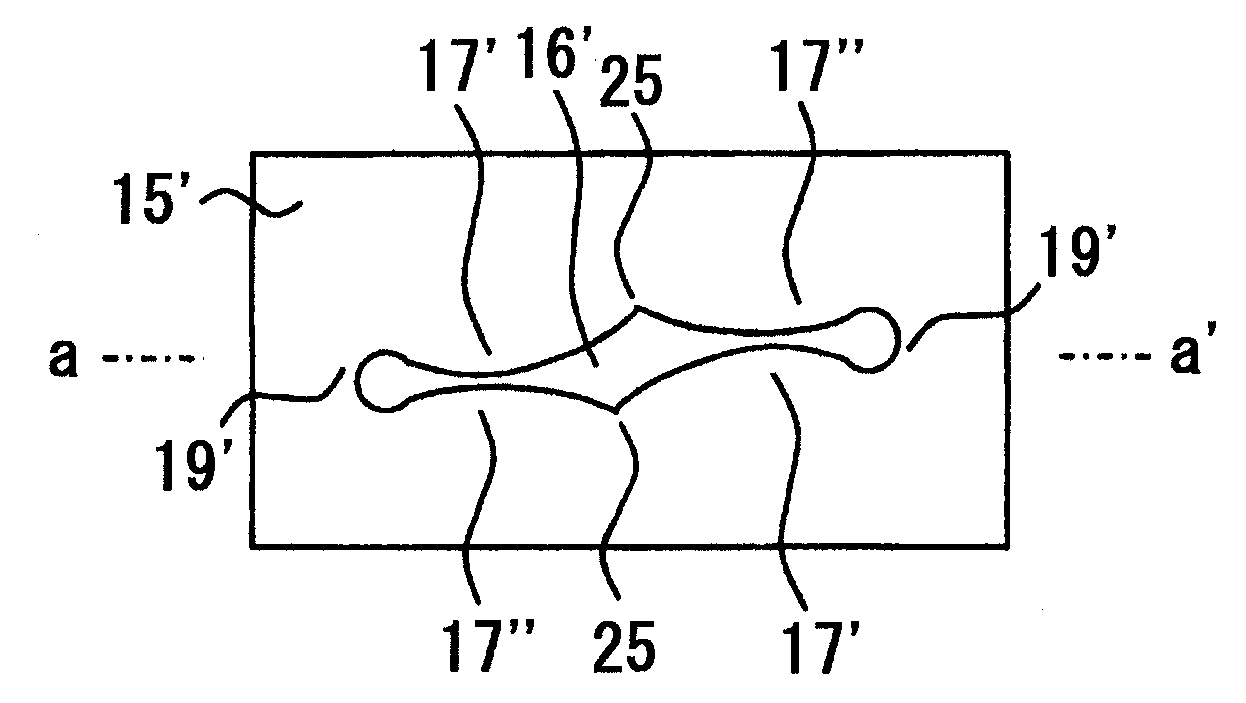

Furthermore, if a sharp projection exists at the position near (a-a′), it easily gets caught on a

joint line of a newly appearing tissue paper and while pulling out the tissue paper, since the next appearing tissue paper lies over the pulling out tissue paper, if the

joint line of the next tissue paper lies on the portion of the pulling out tissue paper where the largest force is applied, the tissue paper can easily fall into the storage box by getting caught.

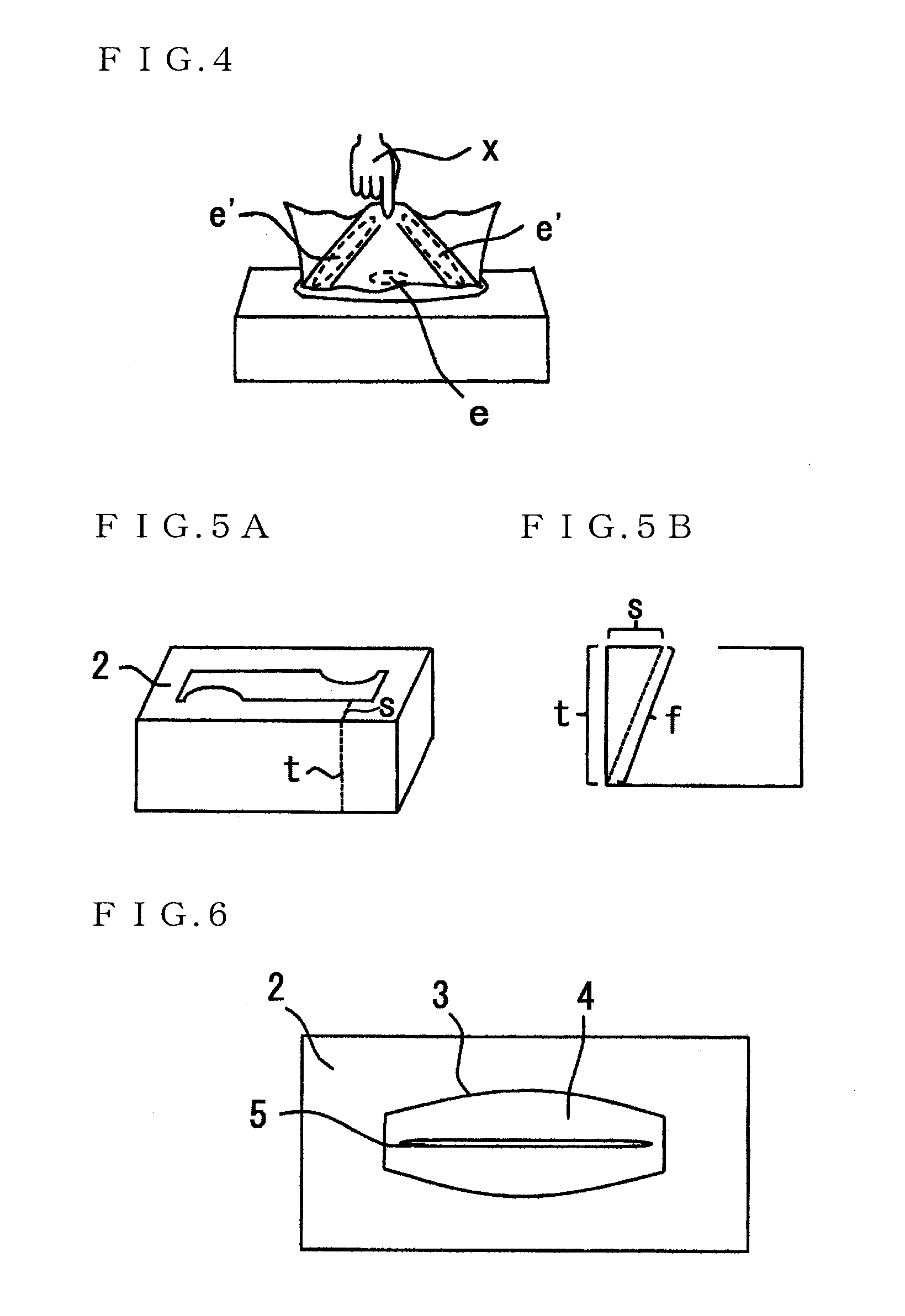

However, according to a method of fixing or removing the tissue paper illustrated in FIG. 7, as the protruding projection is small with a very sharp curve forming the projection and a position held at the time of pulling out the tissue paper is not always at the center, if the tissue paper is held above the projection, there is a possibility of the paper falling into the storage box due to the

joint line of the next appearing tissue paper getting caught on the portion where the projection is overlapped with the portion where the strength is concentrated at the

narrow range of the tissue paper.

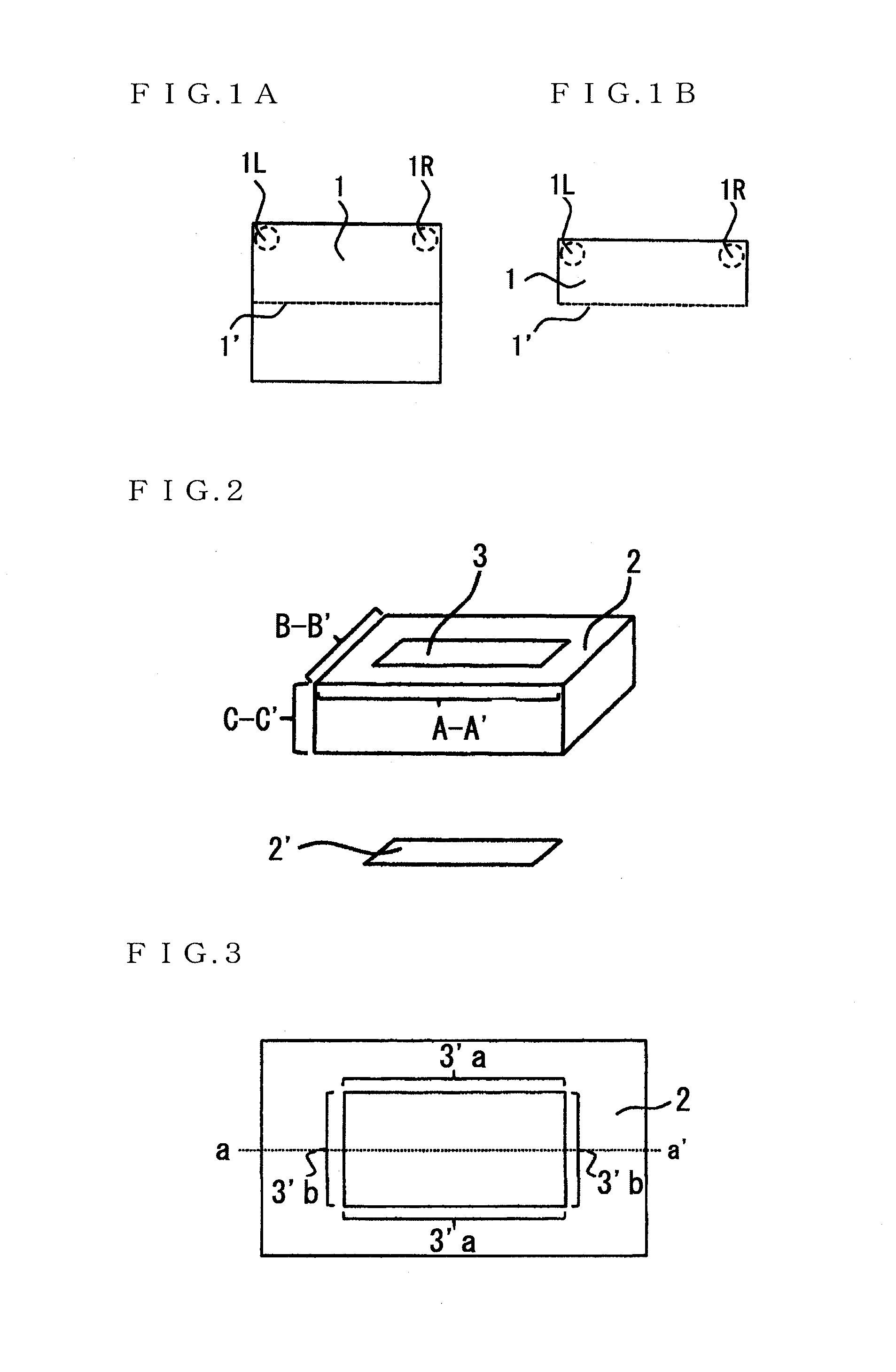

At the time of removing the sheet, since the paper is drawn by inserting a finger from either the left or right side hole, it is obviously more difficult to take the paper out, because it is not possible to take the paper out evenly from the right or left, than a case where the center and its surrounding area are drawn, and the opening has to be reduced to some extent to fix the sheet, otherwise it is difficult to remove the tissue paper.

However, according to FIG. 9, the tissue paper is fixed by narrowing the moving range but, similar to the preceding FIG. 8, the opening has a shape having the apex of the projection near its center, and the same problem described above occurs.

Furthermore, in conventional sheet storage boxes, the projection is raised by inserting the folded line near the bottom of the projection opposite the apex of the projection but, if the projection is raised, the resistance at the time of removing a sheet is reduced and when a sheet falls into the storage box, it takes quite a bit of effort to pull it out since the projection abuts on the finger and if the shape of the projection is complicated, it requires even greater effort.

However, the form mentioned in Japanese Published Unexamined

Patent Application No. 2008-137686 has drawbacks mentioned in the preceding

paragraph 0047 hereof wherein, the opening has only single direction inclination with respect to the front side or back side of the sheet and the opening needs to be extremely inclined to reduce the space of the opening.

When the cover made of cloth, etc., is used to cover the sheet storage box as illustrated in FIG. 16, the central portion of the sheet becomes difficult to remove from the opening and the sheets again slide and fall into the storage box due to the poor method of removing the sheets.

The main method for fixing the sheets is determined by partially pushing the sheet by the projections and since the four projections are not formed by convex curves, tissue paper cannot be fixed or moved without rendering too much resistance to the tissue paper.

However, if the sheet is inserted too much into the slit depending on the shape, the sheet is torn at the time of removing and the space for removing the sheets become too large if a slit is not used and this resulted in a drawback similar to the drawback mentioned in

paragraph 0047 hereof.

There are two apexes of projections on one side rim and one apex on the opposite side rim and if the flap does not work properly, the tissue paper may get caught near the apex of the projection.

However, the flap of the opening is like a covering lid and the flap may get in the way of fingers at the time of removing tissue paper in the storage box which makes it difficult to remove the tissue paper.

In other words, the opening is such that, at the time of beginning to pull out the sheets from the storage box, the next sheet is likely to get caught as the apex of the projection is present near the portion to which force is likely to be applied on the sheet and since the wide finger tip

insertion space cannot be provided in the center of the opening as it is not point symmetric, it requires quite a bit of effort to insert fingers in the storage box from the opening when the sheet falls into the storage box.

In other words, if there are two pairs of projections opposite each other with acute angles, the shape similar to or the same as that mentioned in the preceding FIG. 7 is formed and the same problems as that mentioned in the preceding FIG. 7 occur.

As mentioned above, although pasting the sheet-fixing sheet on the sheet-removing opening is suitable for removing the sheets, it is wasteful from the point of view of resources.

As mentioned above, when the sheet-fixing sheet is not pasted on the opening of the sheet storage box, the fixing of sheets becomes weaker as the opening itself becomes larger due to the excessively wide rim of the opening and when the rims of the opening are made too close, the rim of the opening partially becomes smaller and the resistance to remove the sheets becomes too large.

Login to View More

Login to View More  Login to View More

Login to View More