Burner for a turbine

a turbine and burner technology, applied in the combustion process, hot gas positive displacement engine plants, lighting and heating apparatus, etc., can solve the problems of reducing the formation of nox (particularly thermal nox), and achieve the effect of simple and fast fuel exchange, low emissions, and simple exchangeability of fuel supply pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

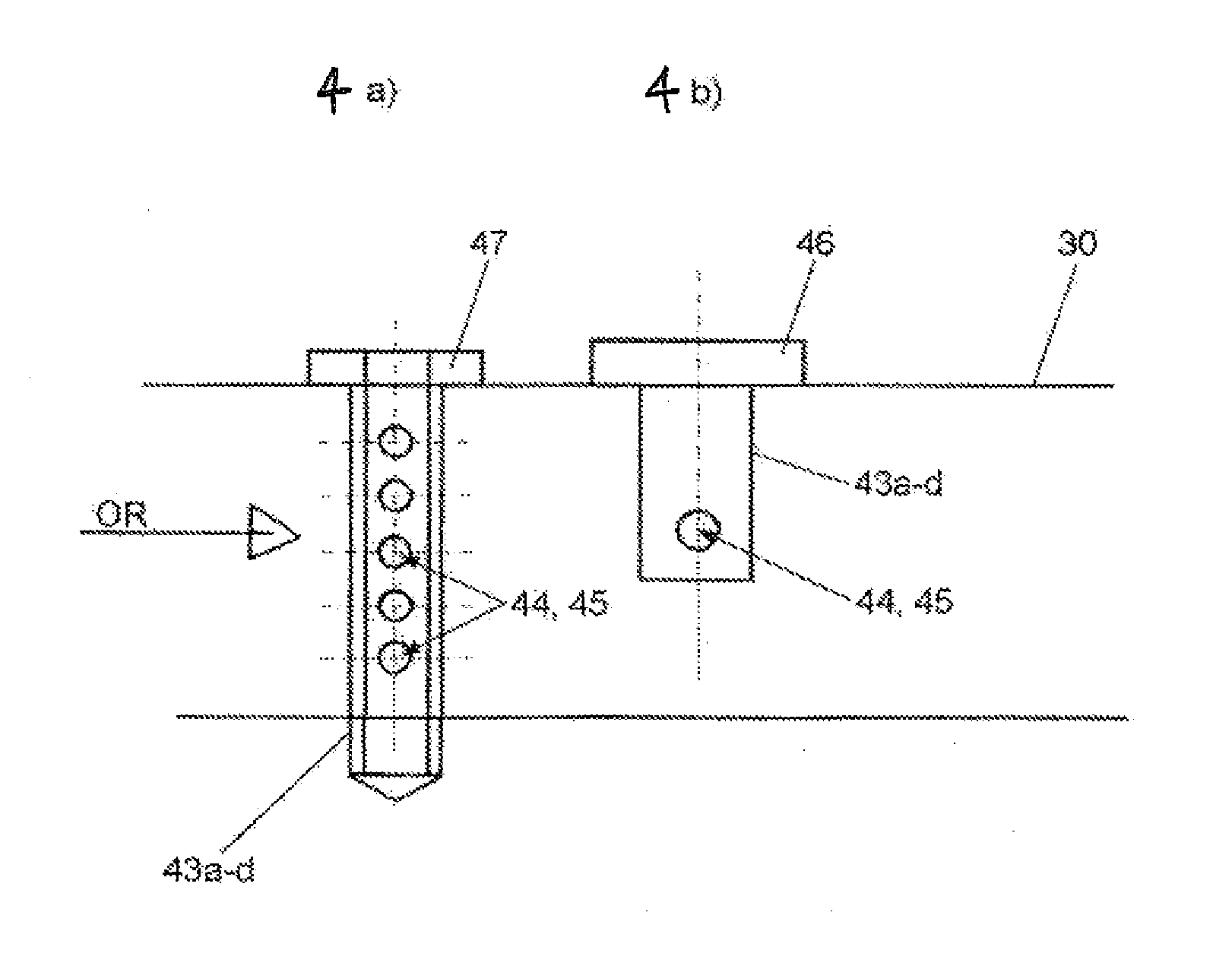

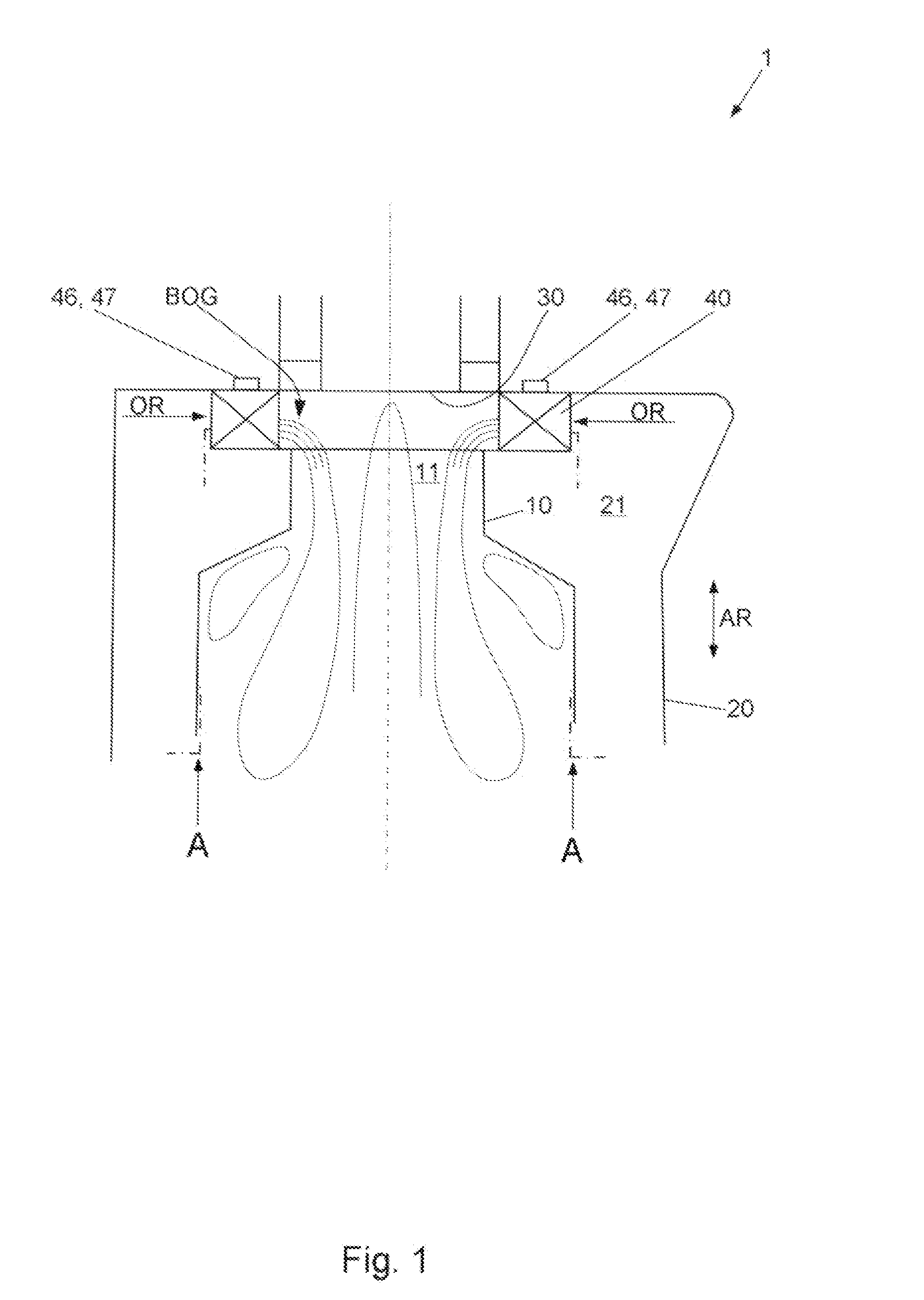

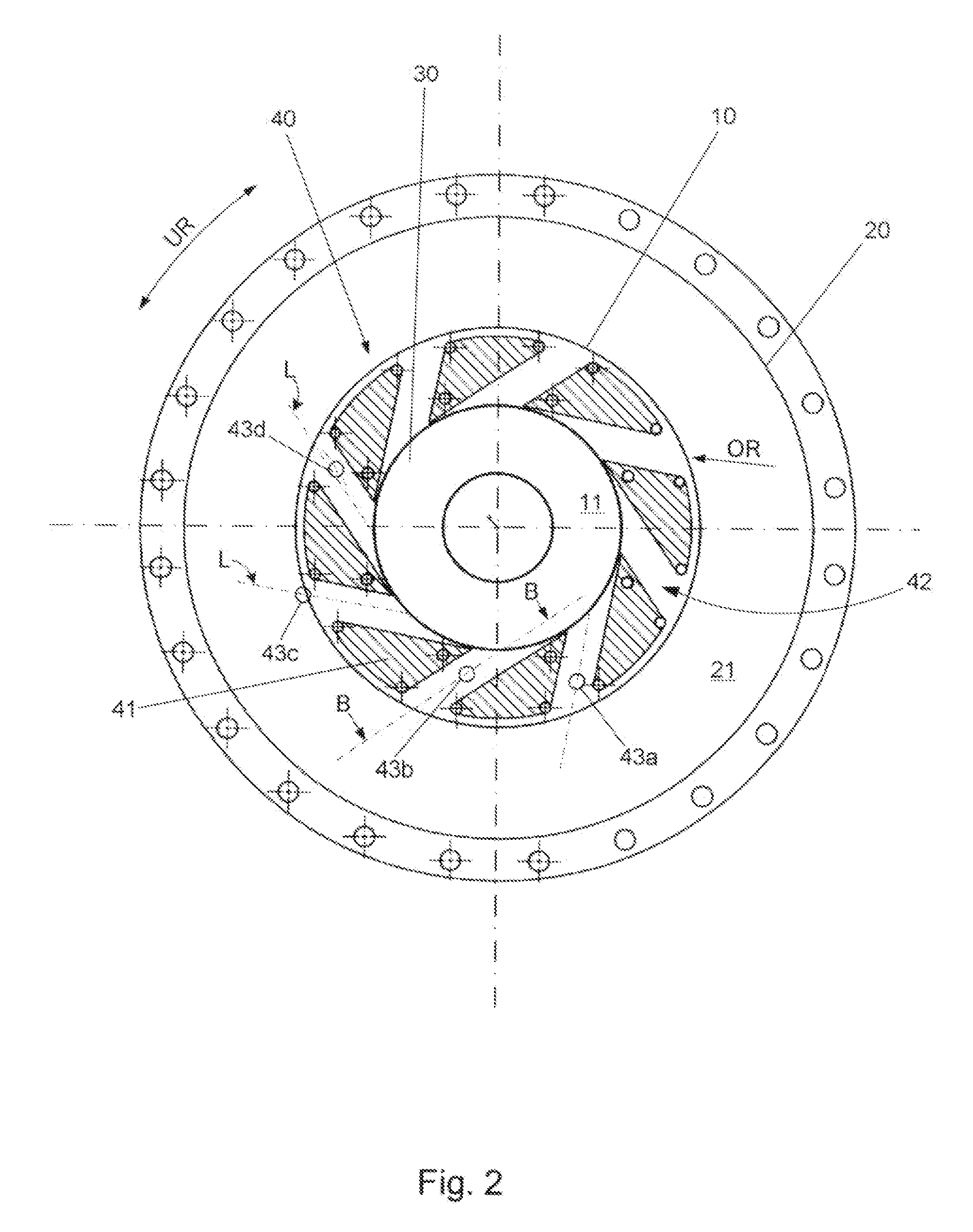

[0038]FIG. 1 shows the construction of a burner 1 of a gas turbine (not shown in its entirety) according to an embodiment of the present invention.

[0039]The burner 1 has a flame tube 10 in which a combustion space 11 is formed and a tubular casing 20 which encloses the flame tube 10 from radially outward at a predetermined distance therefrom so that an oxidant collection chamber 21 is formed between the flame tube 10 and casing 20.

[0040]Combustible gas is provided as fuel for the burner 1, and atmospheric air is provided as oxidant for the combustible gas. This atmospheric air is compressed by a compressor (not shown) and then fed to the oxidant collection chamber 21.

[0041]Further, the burner 1 has a burner bottom 30 which bounds the oxidant collection chamber 21 and combustion space 11 at an axial end of the burner 1 and a swirler 40 which is arranged axially between the flame tube 10 and burner bottom 30 axially adjoining the burner bottom 30 and radially adjoining the oxidant col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com