Process for enzymatic hydrolysis of lignocellulosic materila and fermentation of sugars

a technology of lignocellulosic material and enzymatic hydrolysis, which is applied in the direction of enzymology, biofuels, transferases, etc., can solve the problems of inability to optimize the inability to disclose the optimization process of hydrolysis and fermentation, and inability to convert reducing sugar in general slow and incomplete manner. , to achieve the effect of reducing the dosage of enzymes, and reducing the risk of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Reduction of Process Time by Using Enzyme Composition that Retains Activity for More than 30 Hours at Elevated Temperatures

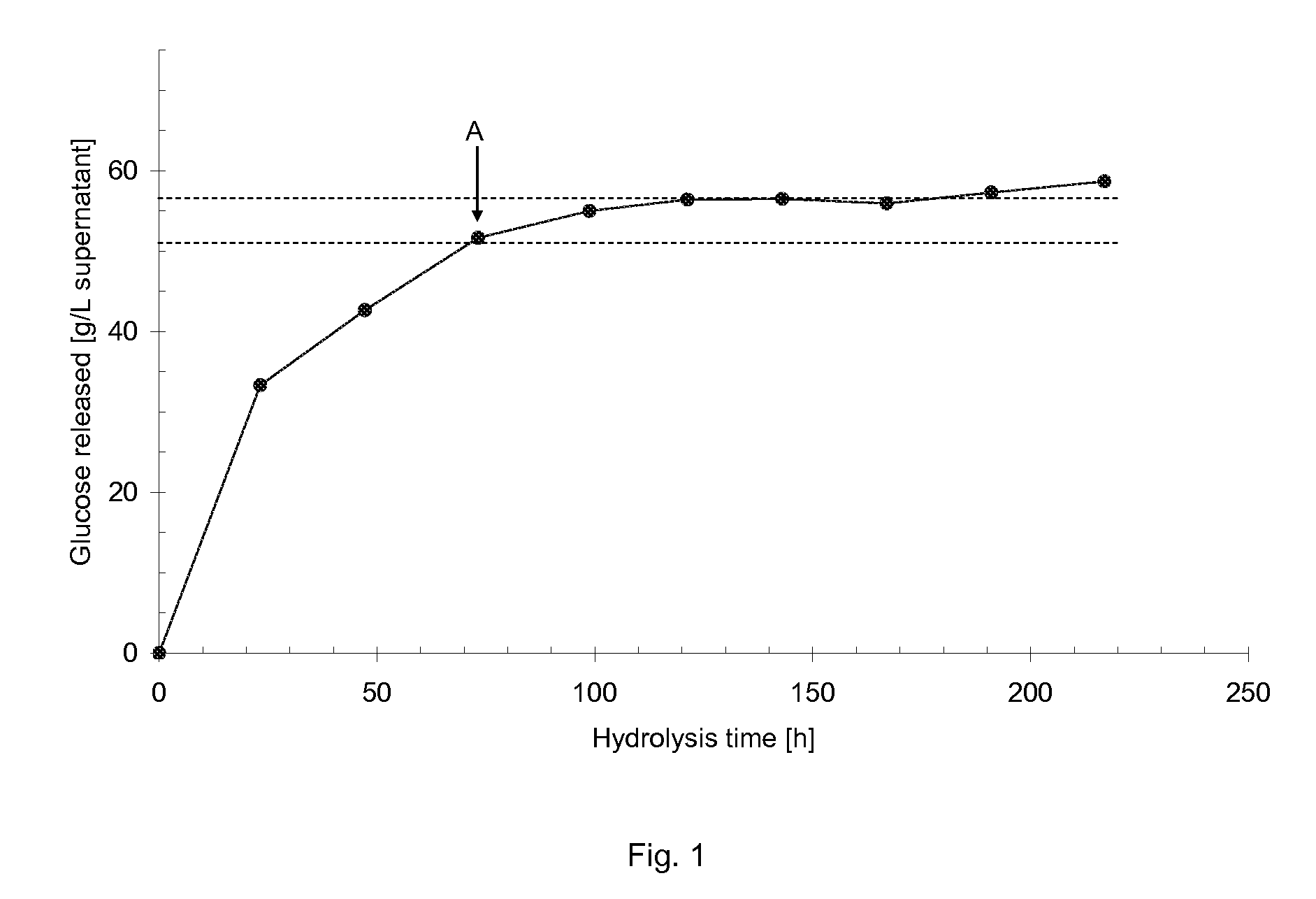

[0173]A comparison is made between a process in which hydrolysis is extended to 72 hours and a process in which the time for hydrolysis is limited to 20 hours to demonstrate the benefit of using the retained activity of the enzyme composition in an extended hydrolysis.

[0174]Materials and Methods

[0175]The method of hydrolysis and fermentation is described in patent application WO2010018105 (PCT / EP2009 / 060098). Pre-treated wheat straw was used as feedstock and washed in tap water of 70 degrees C. until pH was higher than 3, preferably between 6.0 and 6.5. A slurry of 10% w / w of the washed pre-treated feedstock was prepared and pre-incubated at 56 degree C. Enzyme composition was added at a concentration of 0.20 g enzyme composition per g feedstock dry matter. The mixture was divided in two equal portions A and B and incubated at 56 degree C. in an incubator while ...

example 2

Reduction of Enzyme Dosage by Increasing the Process Time with Enzyme Composition that Retain Active for More than 30 Hours at Elevated Temperatures

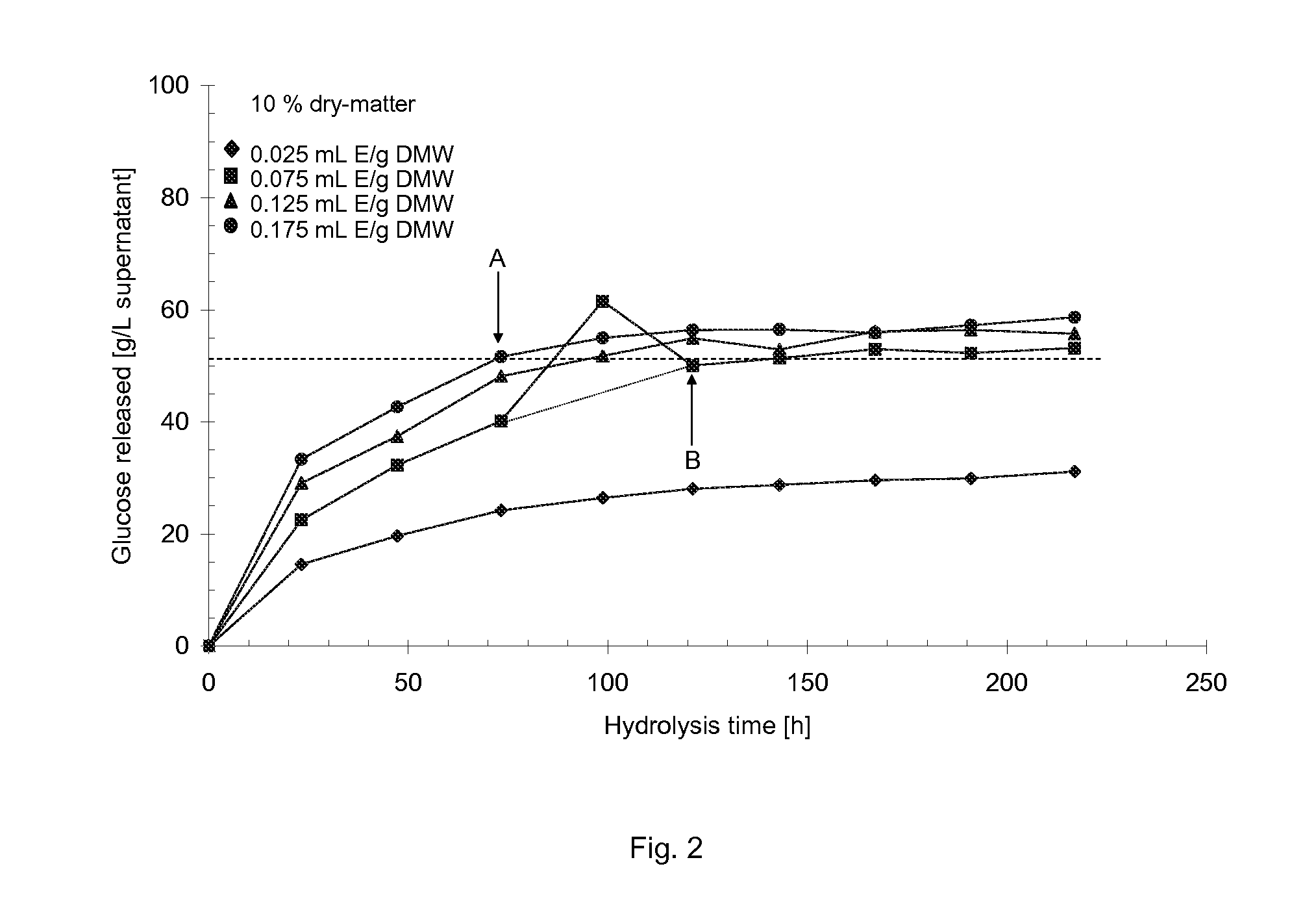

[0183]In another experiment, the property of retaining activity of the enzyme composition was used to compensate low enzyme dosage by extended hydrolysis.

Materials and Methods

[0184]The method of hydrolysis and fermentation as referred to in Example 1 was used.

[0185]A slurry of 10% w / w of the washed pre-treated feedstock was prepared and pre-incubated at 56 degree C. The slurry was divided in to two equal portions A and B. Enzyme composition was added at a concentration of 0.20 g enzyme composition per g feedstock dry matter to portion A and at a concentration of 0.09 g enzyme composition per g feedstock dry matter to portion B. The portions A and B were incubated at 56 degree C. in a incubator while smoothly shaken for 220 hours. During this hydrolysis, samples were taken daily to determine the amount of glucose released from the cellulo...

example 3

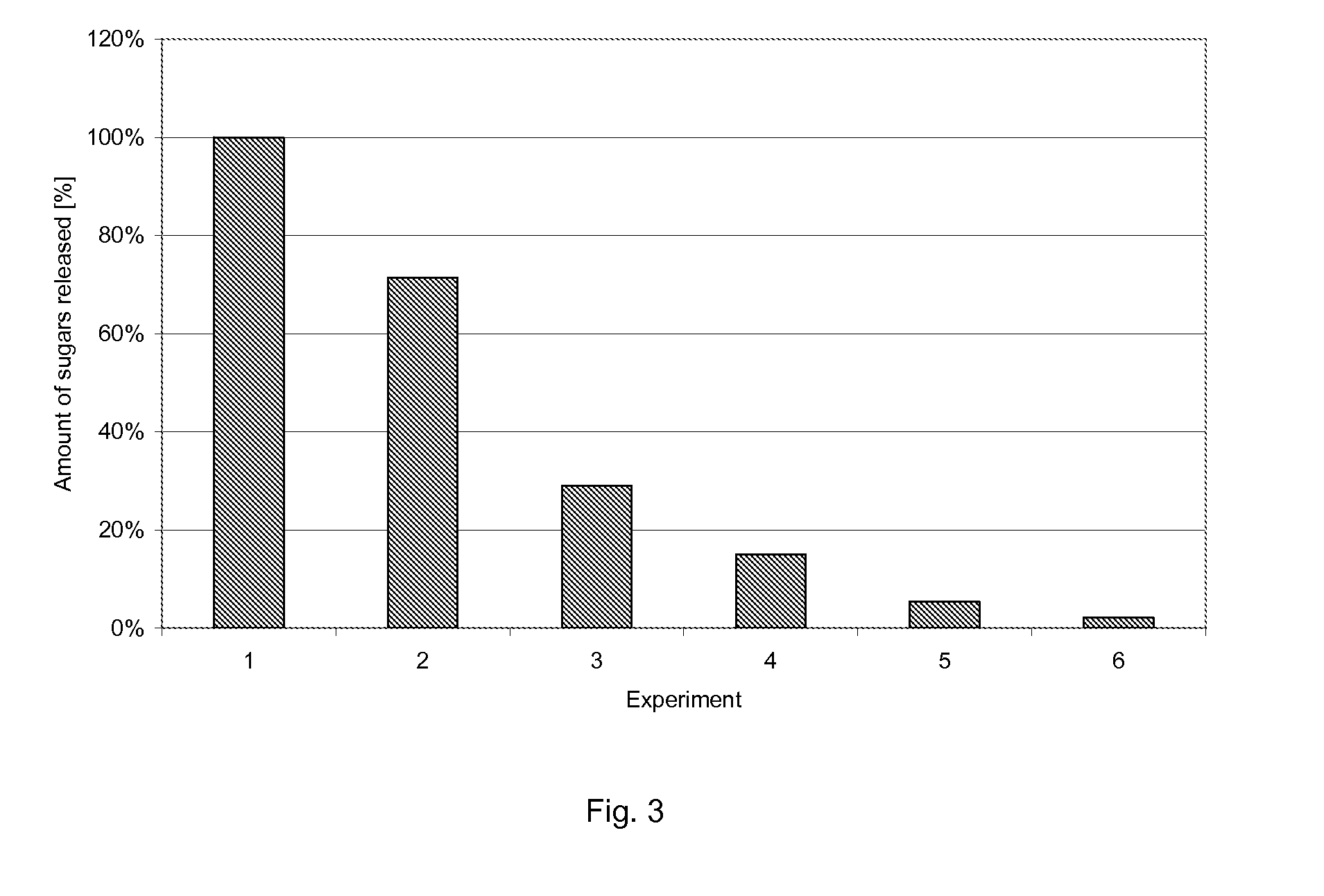

Use of Enzyme Composition with Retaining Activity Allows re-use of Activity After Hydrolysis

[0190]An experiment is performed to demonstrate the use of the liquid fraction of the feedstock-enzyme slurry after hydrolysis, as a source of activity for the hydrolysis in a next process cycle.

[0191]Materials and Methods

[0192]The method of hydrolysis as referred to in Example 1 is used.

A slurry of 10% w / w of the pre-treated feedstock is prepared and pre-incubated at 60 degree C. Enzyme composition is added at a concentration of 0.20 g enzyme composition per g feedstock dry matter and incubated at 56 degree C. in a incubator while smoothly shaken for 120 hours. The slurry is than taken from the incubator and centrifuged at 4500 g. the pellet is washed once, centrifuged and the washing supernatant is combined with the supernatant of the first solid-liquid separation. The combined supernatant is filtrated, using a Z200 filter (a about 0.2 um thick paperfilter by Pall) and concentrated using a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com