Screw compressor

a compressor and screw technology, applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of compressor main body damage, compressor failure to completely close the suction channel with the suction adjustment valve, and the compressor cannot complete the operation, so as to prevent excessive wear, avoid frequent connection and disconnection of the clutch mechanism, and reduce electric power consumption and power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

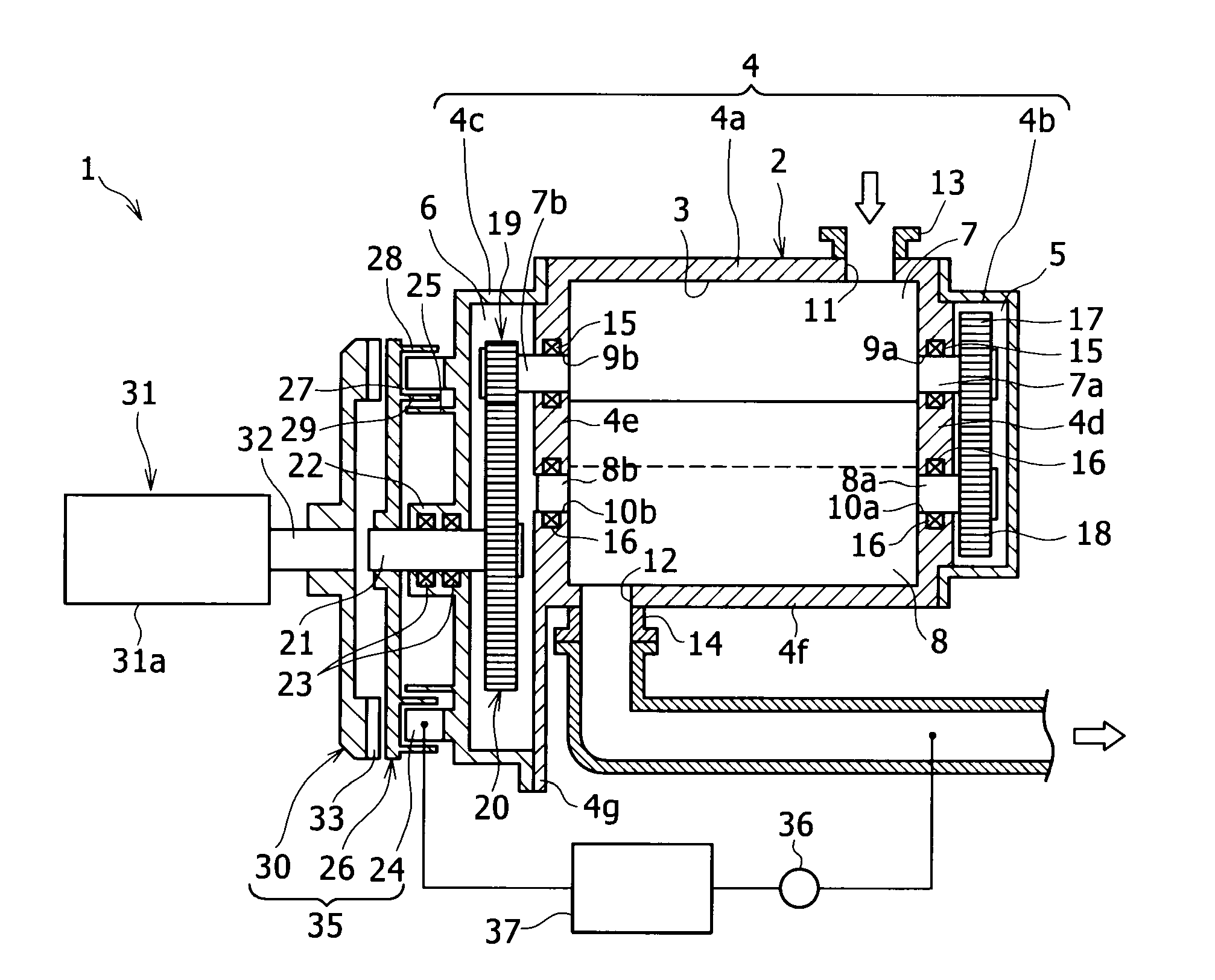

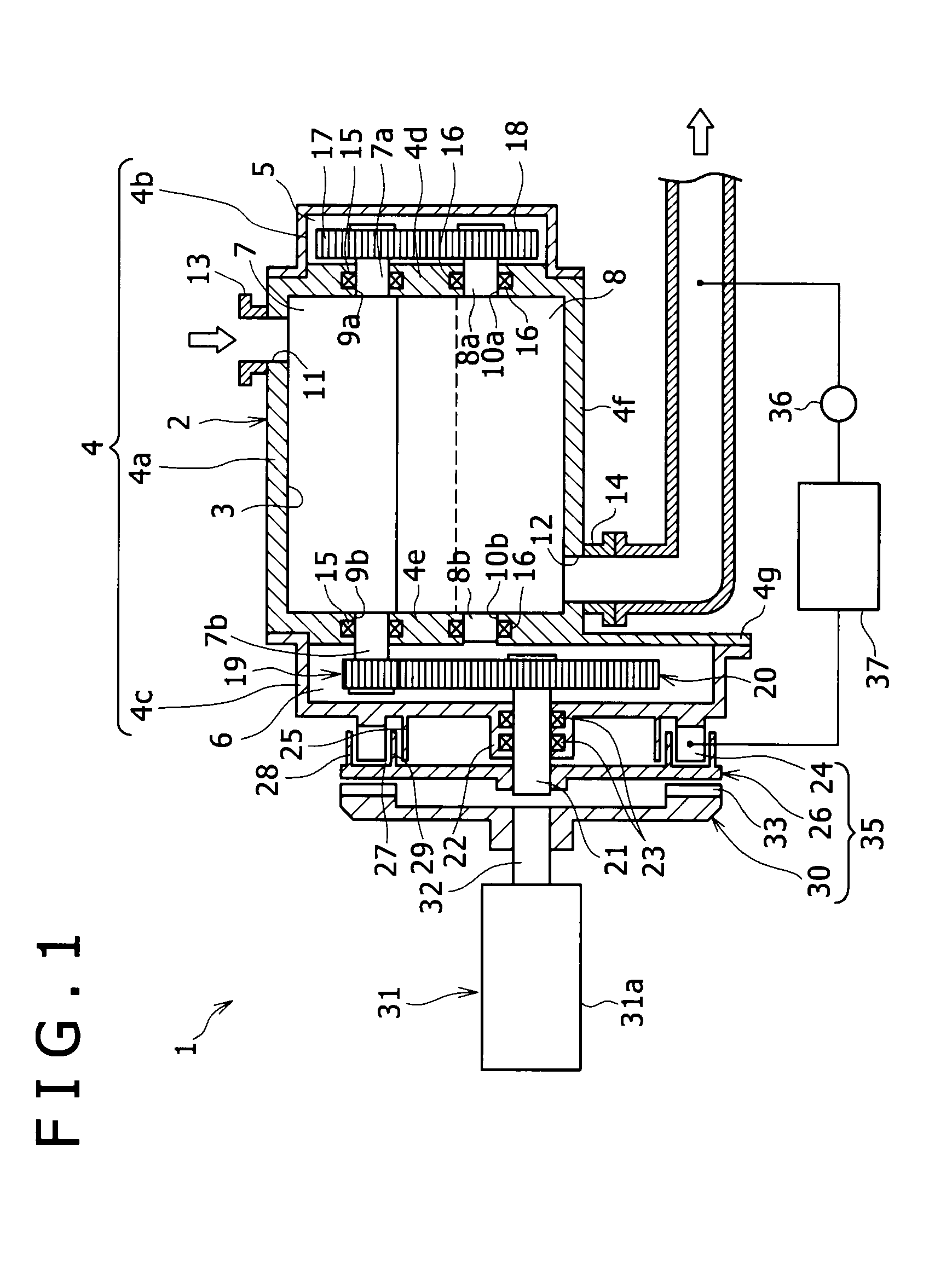

[0016]An embodiment of the present invention is now described with reference to the accompanying drawing.

[0017]FIG. 1 shows a screw compressor 1 according to the present invention. The screw compressor 1 includes a compressor main body 2, a clutch mechanism 35, a motor (driving machine) 31 and a controller 37.

[0018]The compressor main body 2 includes a casing 4. The casing 4 includes: a main casing 4a, in which a compression chamber 3 is formed; an end cover 4b for synchronizing gears, which is mounted to one side of the main casing 4a to form a gear compartment 5 between the end cover 4b and the main casing 4a; and an end cover 4c for transmission, which is mounted to the other side of the main casing 4a to form a gear compartment 6 between the end cover 4c and the main casing 4a.

[0019]In the compression chamber 3 of the main casing 4a, a male screw rotor 7 and a female screw rotor 8 that are engaged with each other are rotatably accommodated.

[0020]A rotor shaft 7a extends from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com