Single component neutrally buoyant proppant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

examples

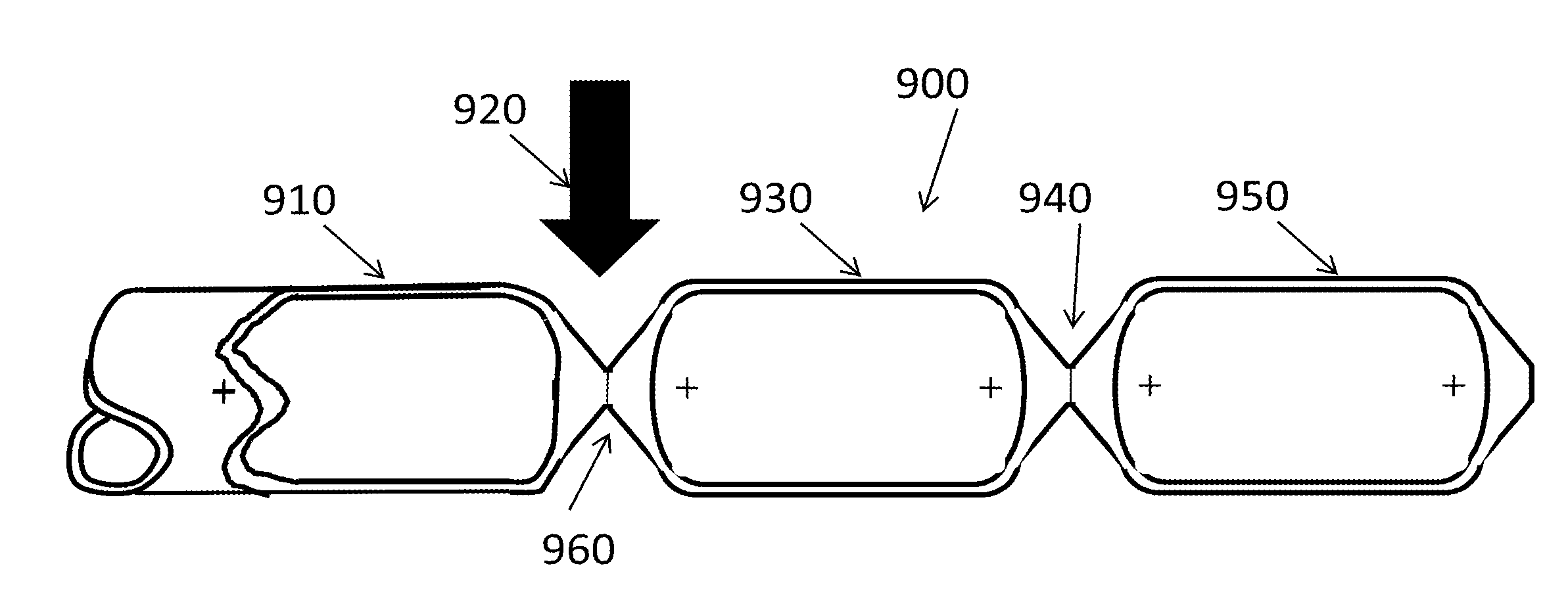

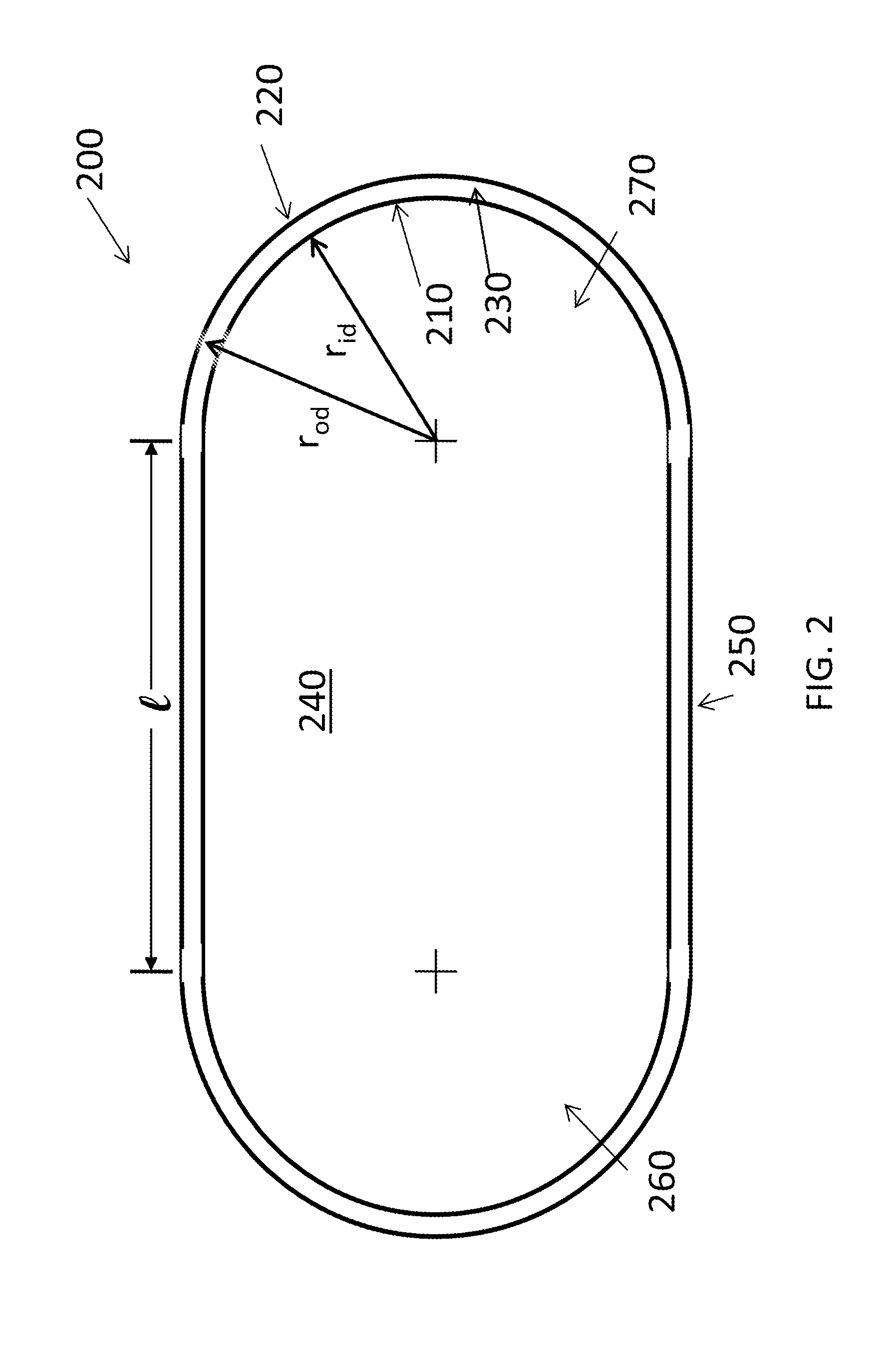

[0121]A substantially neutrally buoyant proppant for use in formations having 6,000 psi closure pressure and 10,000 psi hydrostatic pumping pressure can be developed according the above description. Using borosilicate glass, it is possible to see that a particle that is 300 μm OD and 900 μm length and with a 40 μm wall thickness will have a specific gravity of approximately 1.14. This proppant can be produced by being pulled from a pre-form hollow borosilicate glass rod softened in a furnace into a fiber which is then cut into particles and sealed concurrently using a high temperature plasma torch.

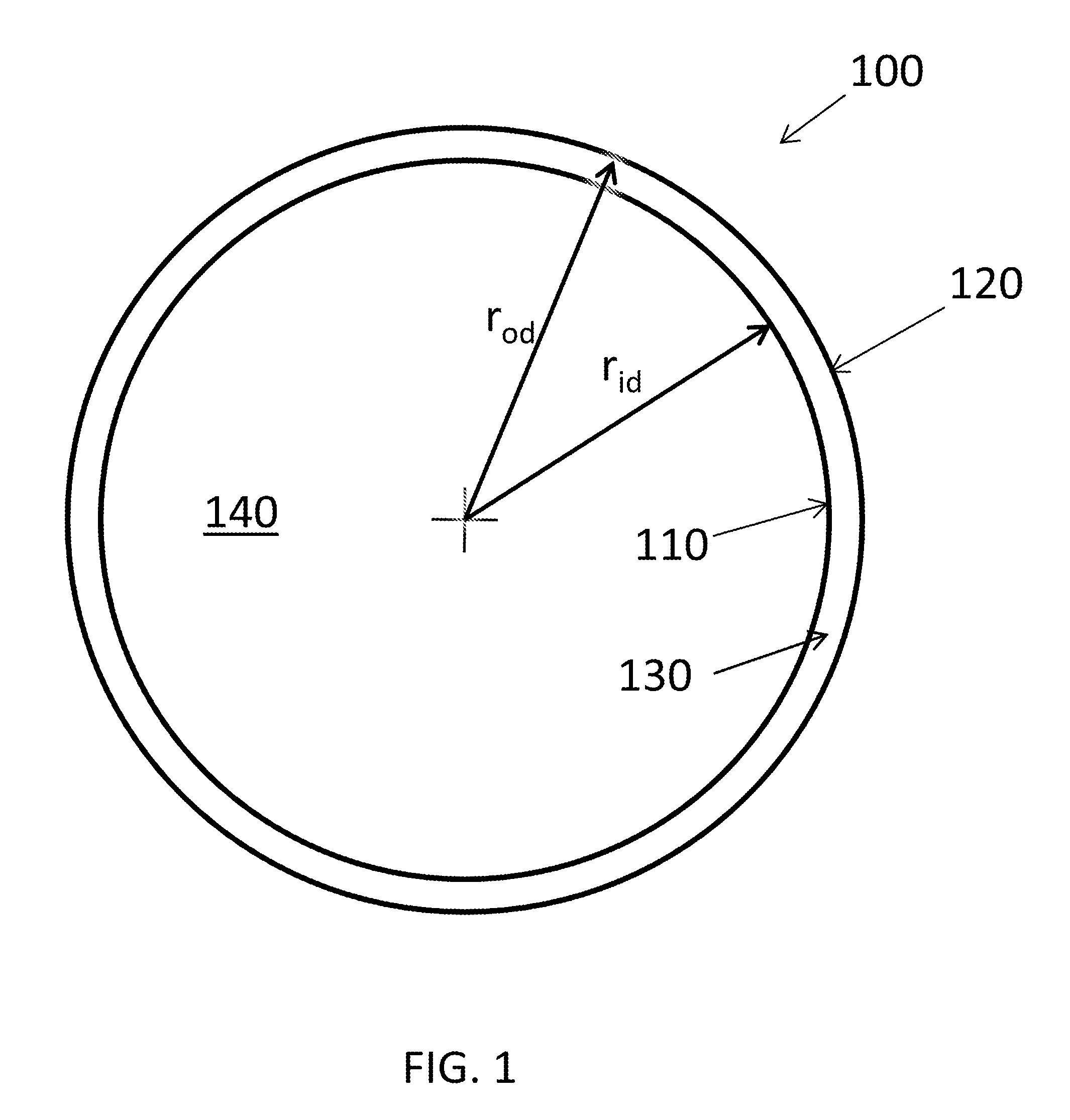

[0122]In a similar approach, proppant particles may be formed of hollow spheres through a sintering process. Spheres in contact with the formation offer essentially point contact for closure stresses. Sphere to sphere contact is the same. This leads to locally high stresses which, for a particular material, may exceed the yield strength of that material. The only mechanism available for co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com