Method for manufacturing papermaking pulp

a technology of papermaking pulp and manufacturing method, which is applied in the field of paper pulp manufacturing process, can solve the problems of pulp whiteness reduction, loss of yield relative to wood, difficulty in bleaching, etc., and achieve the effect of better bleaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

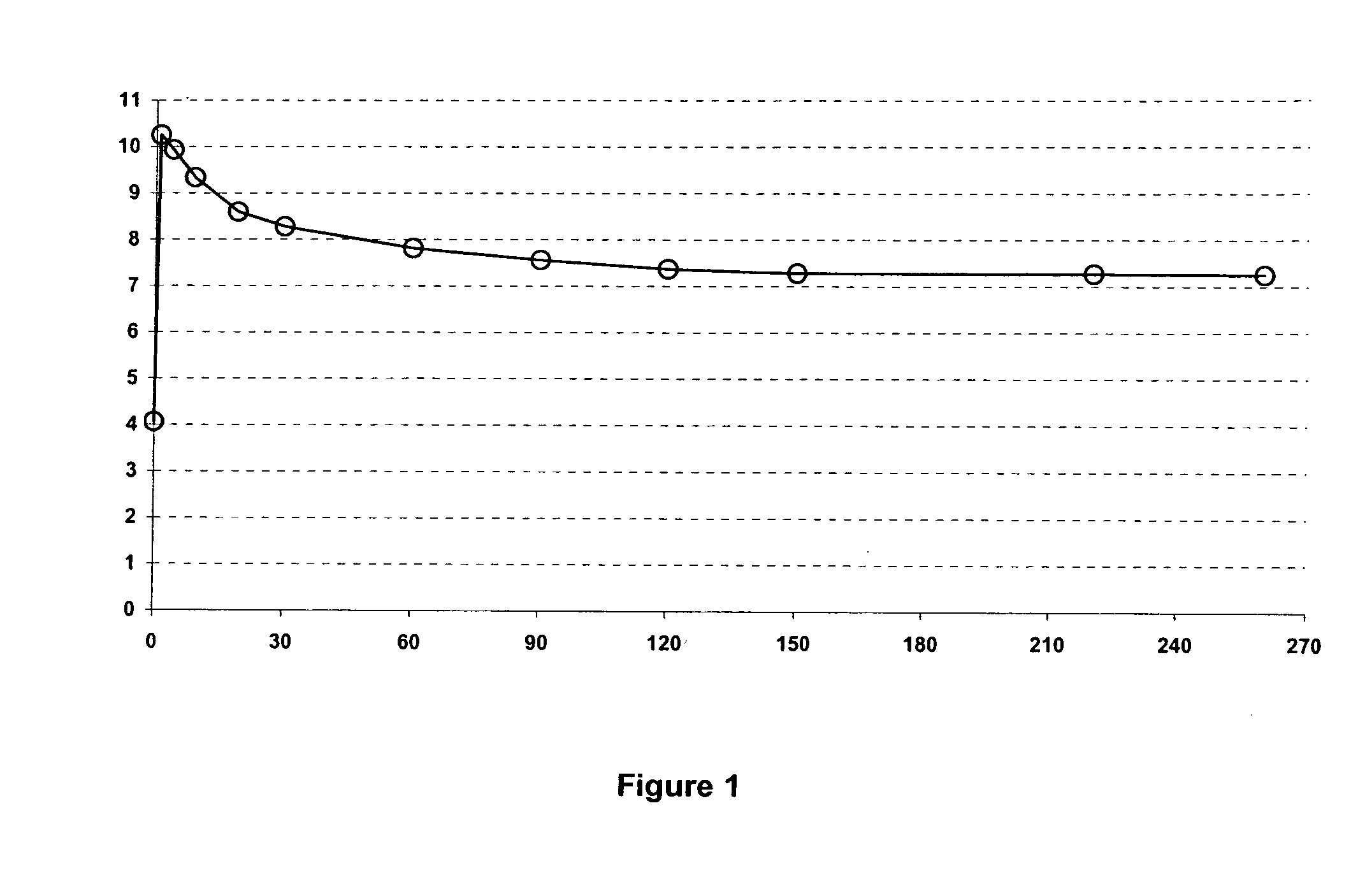

Image

Examples

example 1

[0132]A pine pulp was prepared using the TMP process. The pulp underwent an ozone treatment during the refining phase. More precisely, the reject from the primary refiner was treated with 2% ozone, the pH being adjusted by adding 5 kg of caustic soda per tonne of pulp, and then the ozone-treated reject was mixed with the accepted fraction from the secondary refiner. The whiteness of the pulp after the ozone refining / treatment was 47.3%.

[0133]After the ozone refining / treatment, a chelation step was provided, during which the pulp was treated with 4 kg of DTPA per tonne of pulp, with a consistency of 4% and at a temperature of 70° C. and a pH of 6-7 for 1 hour.

[0134]After the chelation step, the pulp underwent a bleaching step, with a consistency of 20%, at a temperature of 70° C. for a time of 2 hours.

[0135]To prepare pulp A (comparative example), the following parameters were also used:[0136]no deacidification step between the ozone refining / treatment and the chelation; and[0137]ble...

example 2

[0156]A pine pulp was prepared using the TMP process. The pulp underwent an ozone treatment during the refining phase. More precisely, the reject from the primary refiner was treated with 2% ozone, the pH not being adjusted, and then the ozone-treated reject was mixed with the accepted fraction from the secondary refiner. The whiteness of the pulp after the ozone refining / treatment was 48.3%.

[0157]After the ozone refining / treatment, a chelation step was provided, during which the pulp was treated with 4 kg of DTPA per tonne of pulp, with a consistency of 2-3% and at a temperature of 70° C. and a pH of 6-7 for 1 hour.

[0158]After the chelation step, the pulp underwent a bleaching step, with a consistency of 20%, at a temperature of 70° C. for a time of 2 hours.

[0159]To prepare pulp E, the following parameters were also used:[0160]a deacidification step lasting 3 hours between the ozone refining / treatment and the chelation, by means of 20 kg of sodium hydroxide per tonne of pulp (7.4 p...

example 3

[0177]A spruce pulp was prepared using the TMP process. The pulp underwent an ozone treatment during the refining phase. More precisely, the reject from the primary refiner was treated with 2% ozone, the pH not being adjusted, and then the ozone-treated reject was mixed with the accepted fraction from the secondary refiner. The whiteness of the pulp after the ozone refining / treatment was 51.2%.

[0178]After the ozone refining / treatment, a chelation step was provided, during which the pulp was treated with 4 kg of DTPA per tonne of pulp, with a consistency of 2-3% and at a temperature of 70° C. and a pH of 6-7 for 1 hour.

[0179]After the chelation step, the pulp underwent a bleaching step, with a consistency of 20%, at a temperature of 70° C. and for a time of 2 hours.

[0180]To prepare pulp I (comparative example) the following parameters were also used:[0181]a deacidification step lasting 5 to 10 minutes between the ozone refining / treatment and the chelation, by means of 10 kg of sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com