Compound and method for producing the same

a technology of compound and method, applied in the direction of transportation and packaging, special tyres, coatings, etc., can solve the problems of low thermal stability, high hygroscopicity of polyurethane, and the inability to find any disclosure about the sol-gel process with basic catalys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The present invention is to provide a compound and method for producing the same. The compound is a polyurethane composite material and the method for producing the compound without any extra catalyst. Embodiments of the present invention are disclosed as followed.

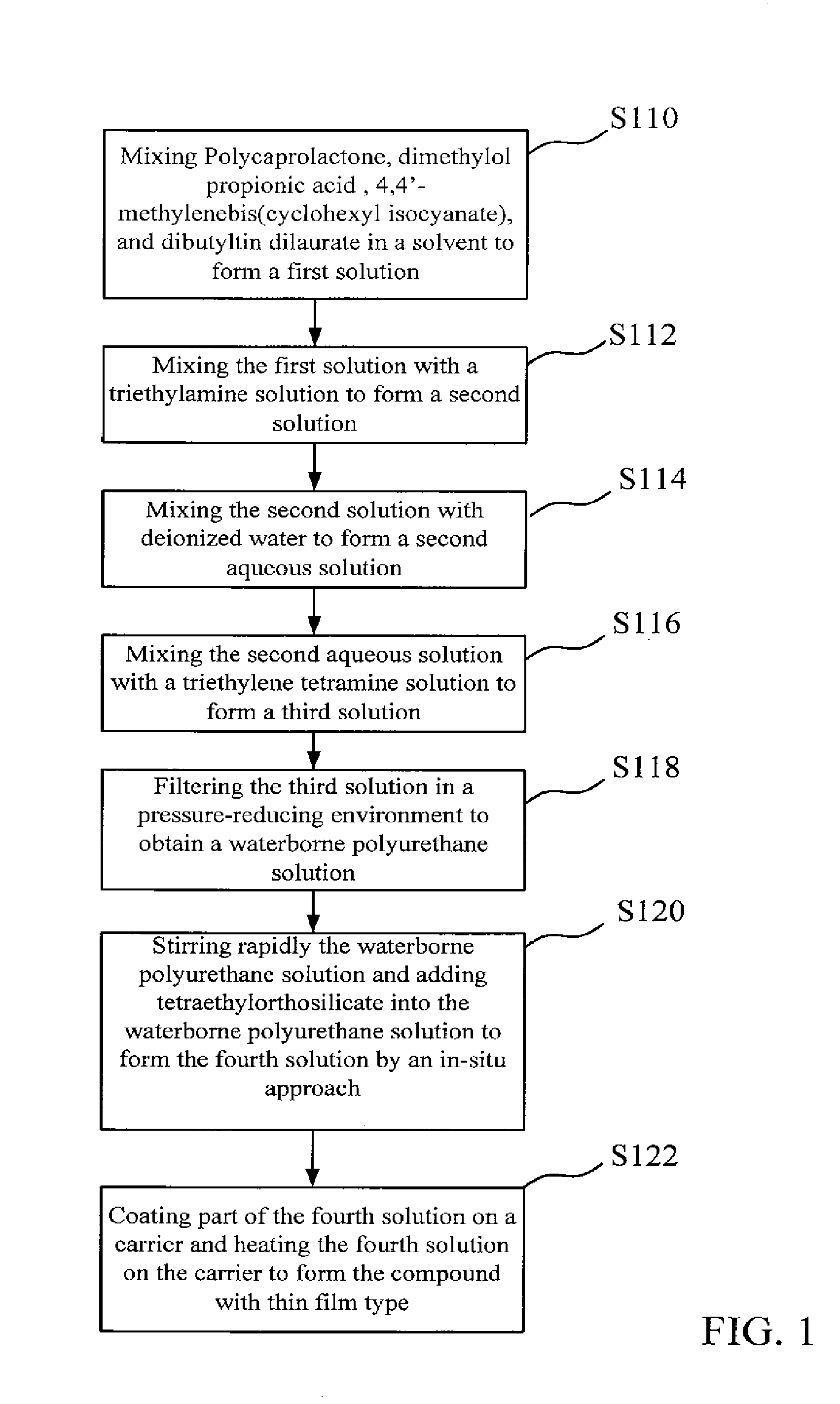

[0024]Please refer to FIG. 1. FIG. 1 illustrates a flow chart according to one embodiment of the present invention.

[0025]As shown in FIG. 1, in one embodiment, the method comprises the following steps:

[0026]In step S110, PCL, DMPA, H12MDI, and DBT are mixed in a solvent to form the first solution. Subsequently, in step S112, the first solution is mixed with a TEA solution to form a second solution. In step S114, the second solution is mixed with deionized water to form a second aqueous solution. In step S116, the second aqueous solution is mixed with TETA solution to form a third solution. In step S118, the third solution is filtered in a pressure-reducing environment to obtain a waterborne polyurethane solution. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| room temperature | aaaaa | aaaaa |

| room temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com