Laser illumination system with reduced speckle

a laser source and annealing device technology, applied in the direction of polarising elements, instruments, manufacturing tools, etc., can solve the problems of reducing the image quality of components illuminated with laser sources, affecting the image quality of laser sources, and prone to speckle of laser sources,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

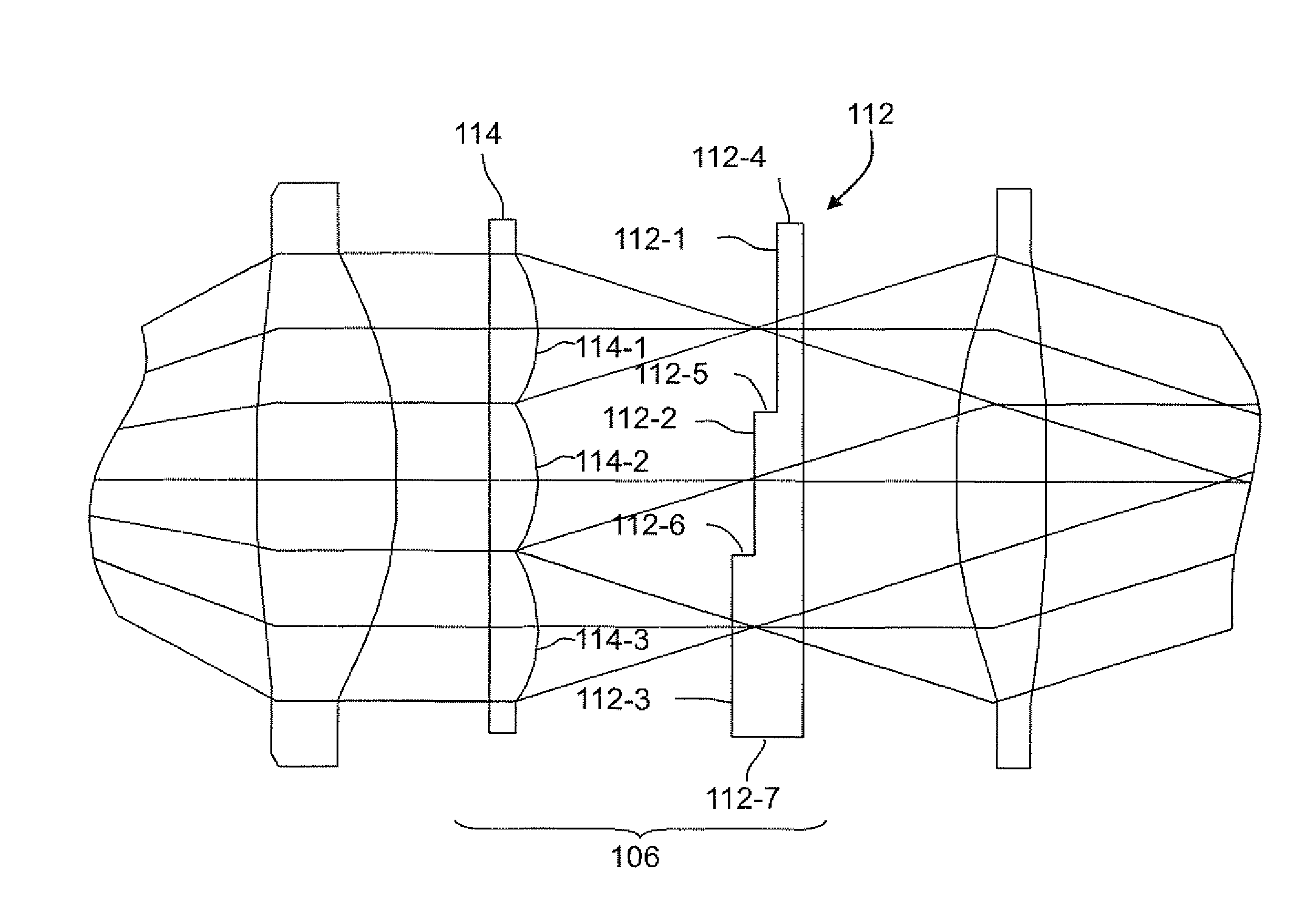

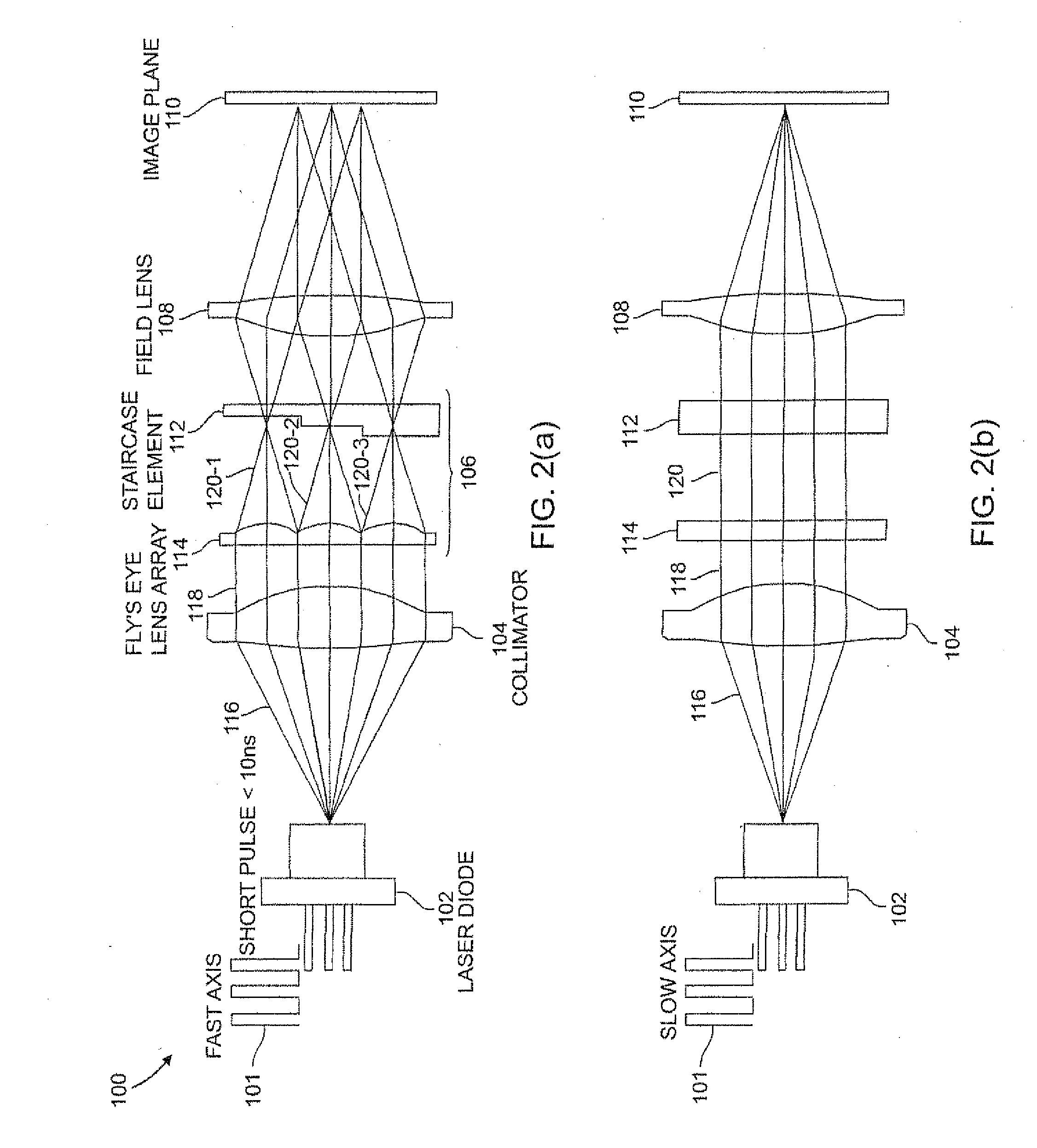

[0044]FIGS. 2(a) and 2(b) depict cross-sectional diagrams of an exemplary laser beam homogenizer 100 (also referred to herein as homogenizer 100), according to the present invention. In particular, FIG. 2(a) is a cross-section diagram of homogenizer 100 with respect to a fast axis of laser source 102; and FIG. 2(b) is a cross-section diagram of homogenizer 100 with respect to a slow axis of laser source 102. FIG. 3 is a magnified view of the despeckle elements or despeckle unit 106 shown in FIGS. 2(a) and 2(b).

[0045]Homogenizer 100 includes short pulse laser driver 101, laser source 102, collimator 104, despeckle elements 106 and field lens 108. In operation, laser source 102 emits coherent light beam 116. Collimator 104 collimates coherent light beam 116 received from laser source 102, to form collimated light beam 118. It is understood that collimator 104 may collimate coherent light beam 116 to form collimated light (collimated light with no divergence) or approximately collimate...

third embodiment

[0092]Since linearly polarized (e.g., p-polarized) and orthogonally polarized (e.g., s-polarized) beams do not interfere with each other, no step needs to be added to one of the two adjacent positions on the staircase configuration. Accordingly, wave plates 602-1, 602-2 and 602-3 may be formed directly on the physical steps 612-1, 612-2, and 612-3 without increasing the step height. Accordingly, a thickness of the despeckle element 600 may be reduced to half of the thickness and half the number of physical steps of a despeckle element where the optical steps are formed only using physicals steps as optical path difference elements (e.g., three physical steps in FIG. 6 as opposed to six physical steps of a corresponding despeckle element similar to despeckle element 106 of FIG. 2(a) but having six steps). Thus, the despeckling element 600 according to the present invention has a reduced total thickness and is very compact.

[0093]Furthermore, although FIG. 6 illustrates the wave plates...

fourth embodiment

[0101]Since right circular polarization and left circular polarization beams do not interfere with each other, no step needs to be added to one of the two adjacent positions on the staircase configuration. Accordingly, both first wave plate 702 and second wave plate 704 may be formed directly on staircase element 712 without increasing the step height. Thus, the thickness of despeckle element 700 may be reduced to half of the thickness and half the number of physical steps (e.g., three physical steps as opposed to six physical steps) compared to a step of despeckle element 106 (FIG. 2(a)) but having six steps. Thus, the despeckling element 700 according to the present invention has a reduced total thickness and is very compact.

[0102]Furthermore, although FIG. 7 illustrates the wave plates 702 and 704 as being disposed on the steps 712-1, 712-2, and 712-3 of the staircase element 712, it should be understood that the wave plates 702 and 704 are not limited to being disposed on the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| output power | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

| coherence length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com