Fire Resistant Steel Structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

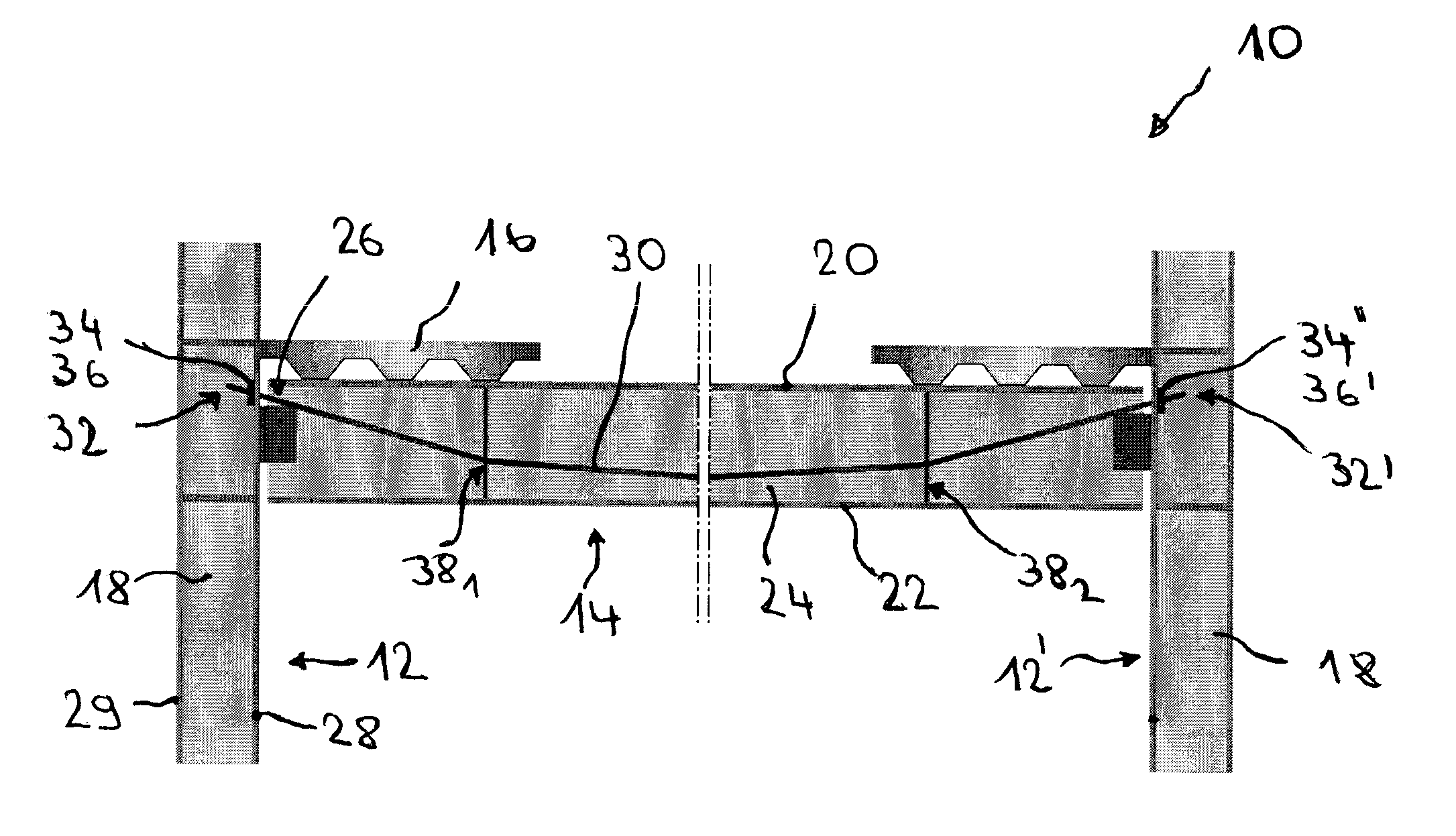

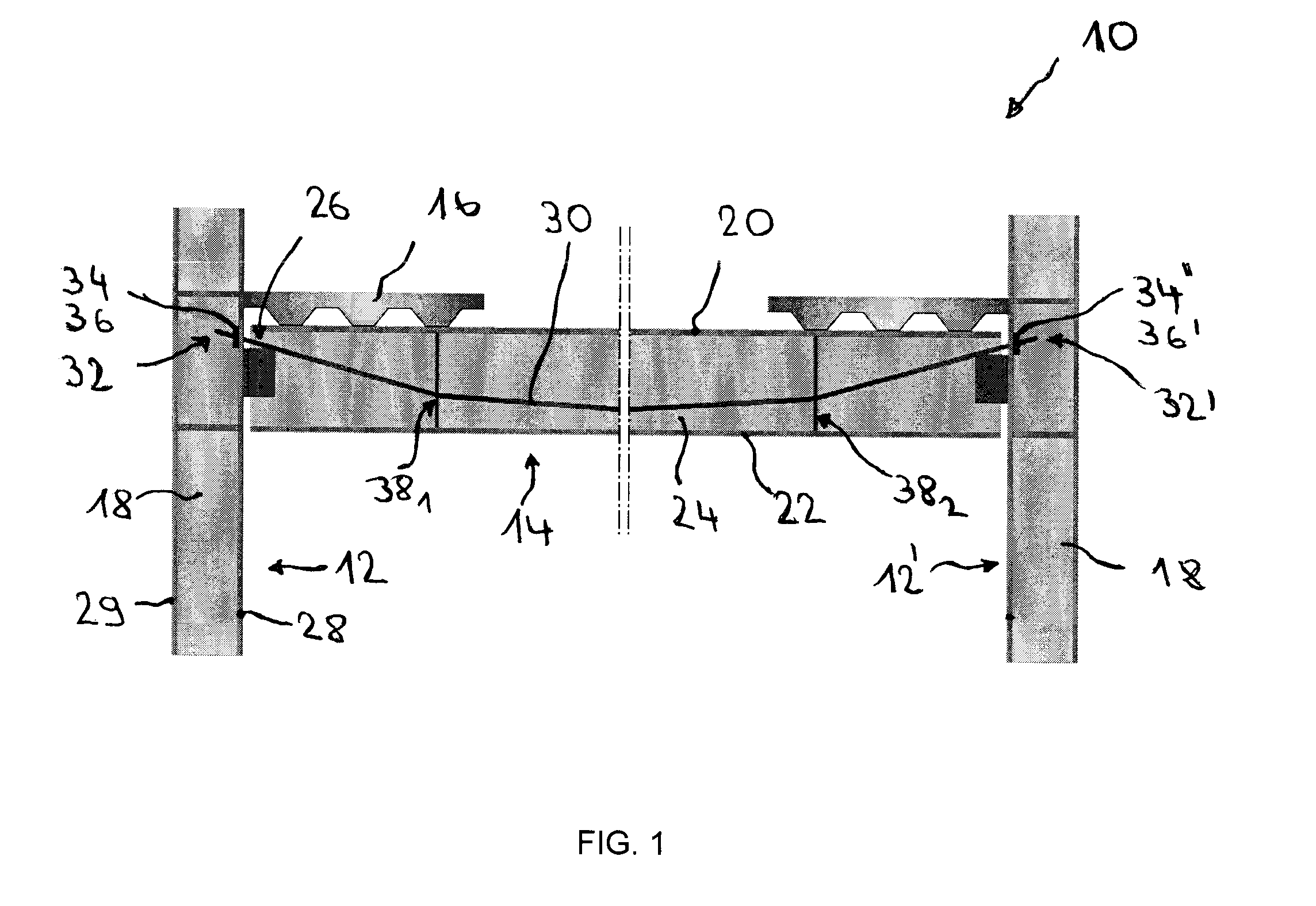

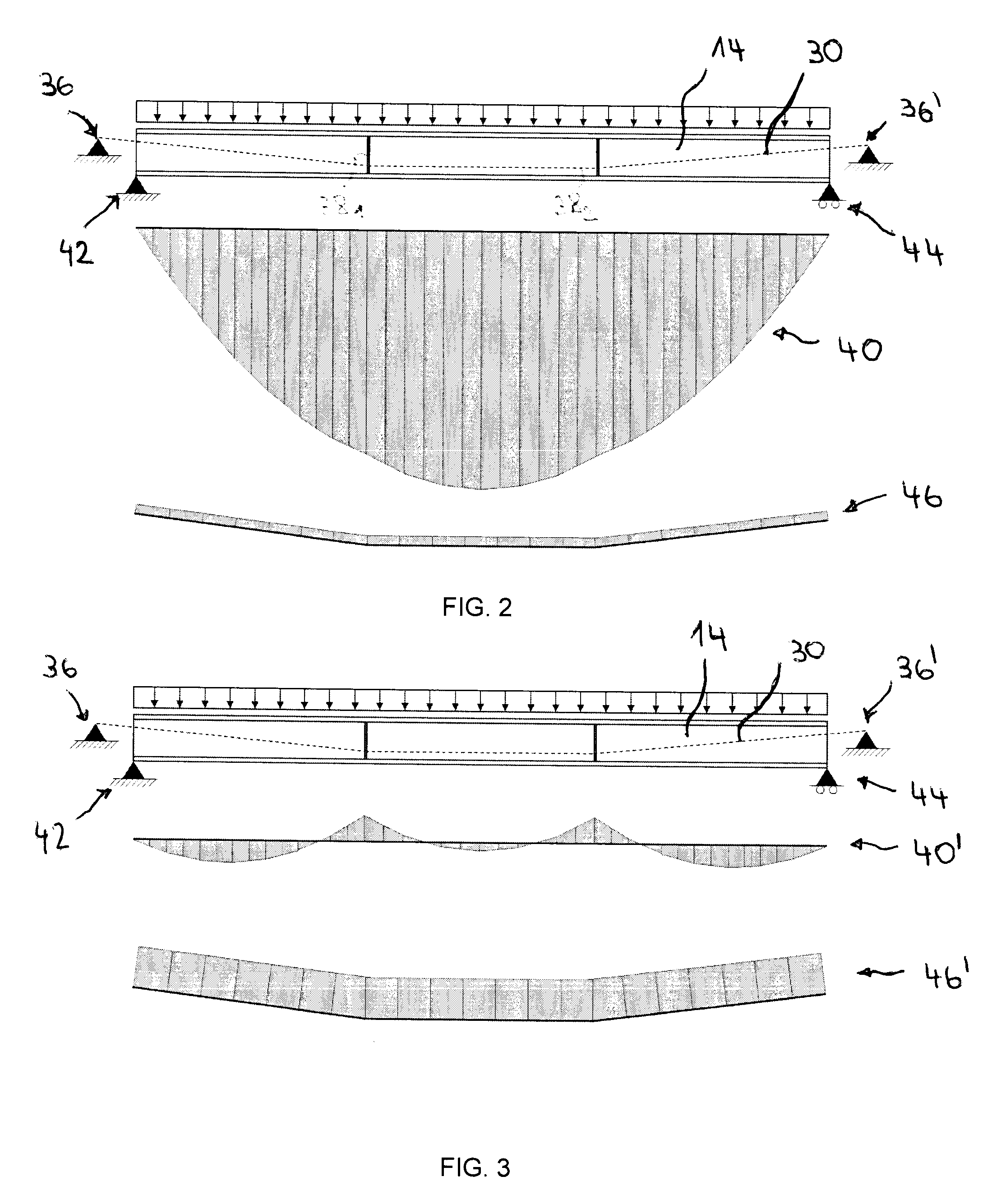

[0042]FIG. 1 shows a fire resistant steel structure 10 in accordance with the invention. This steel structure 10 comprises two columns 12, 12′ (i.e. vertical structural members) forming a support for a steel beam 14 (i.e. a horizontal structural member) at two horizontally spaced locations. The steel beam 14 serves as support element for a slab 16, in this case e.g. a concrete slab with profiled steel sheets.

[0043]The columns 12, 12′ shown in FIG. 1 are H-shaped steel beams with a reinforced concrete filling 18 between the flanges (such columns are generally called composite columns). The reinforced concrete filling 18 warrants that the columns 12, 12′ maintain their load bearing function during the required time of fire exposure. Alternatively, the columns 12, 12′ might also be steel profiles protected with a fireproof casing made e.g. of silicate or gypsum plates with or without mineral fiber insulations, with spray applied fireproofing materials, intumescent paints or coatings, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com