Cassette Puller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

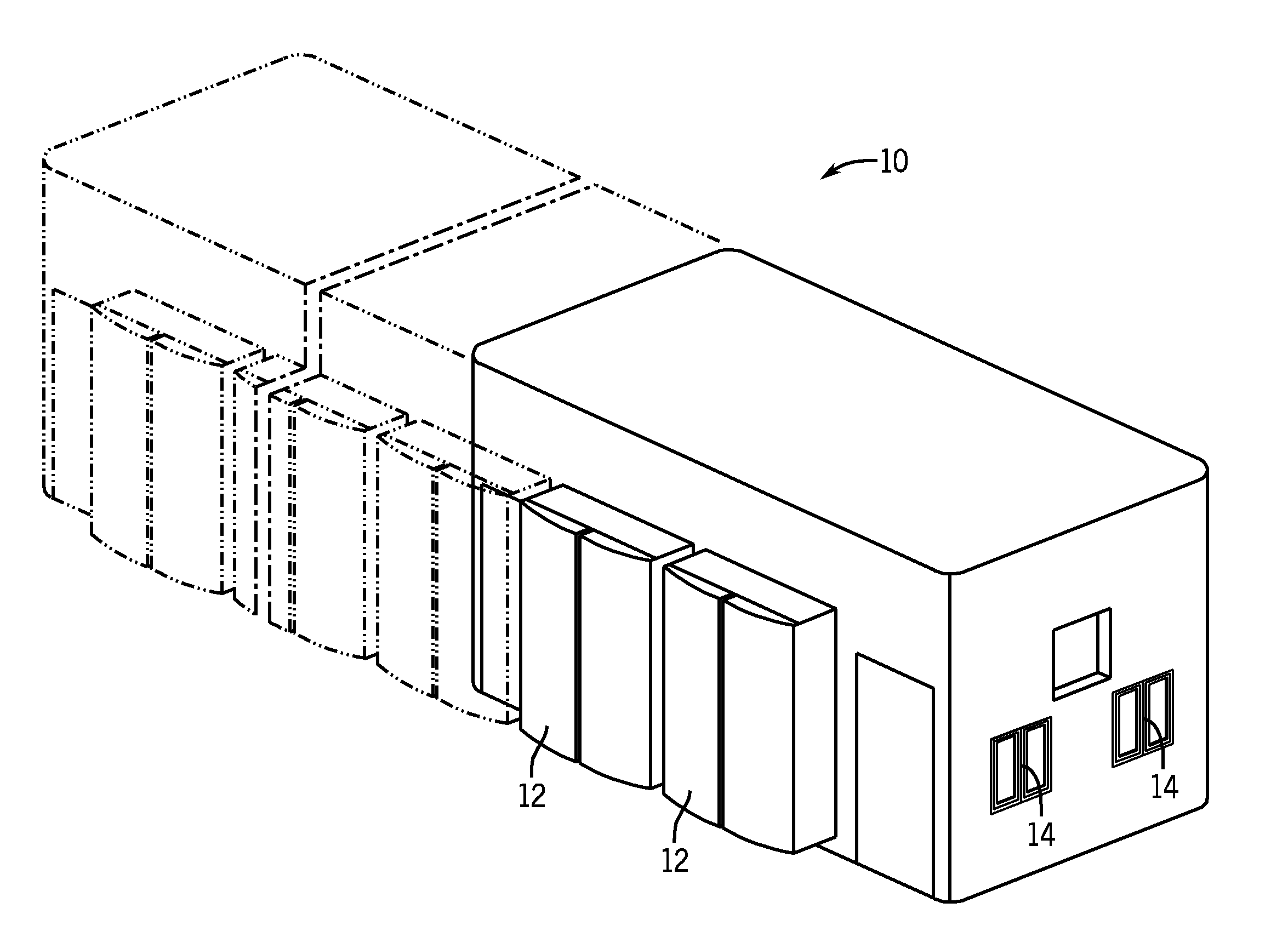

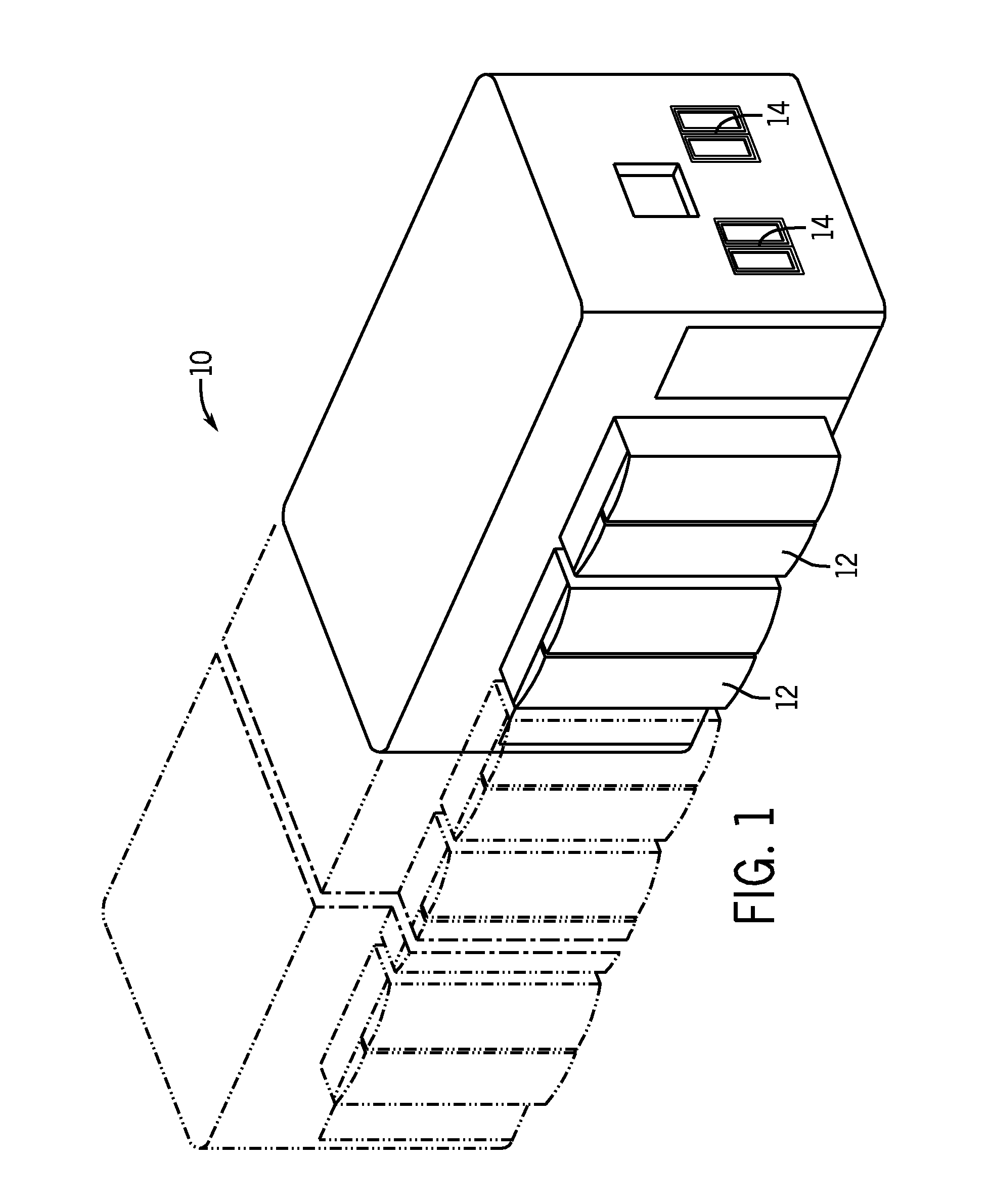

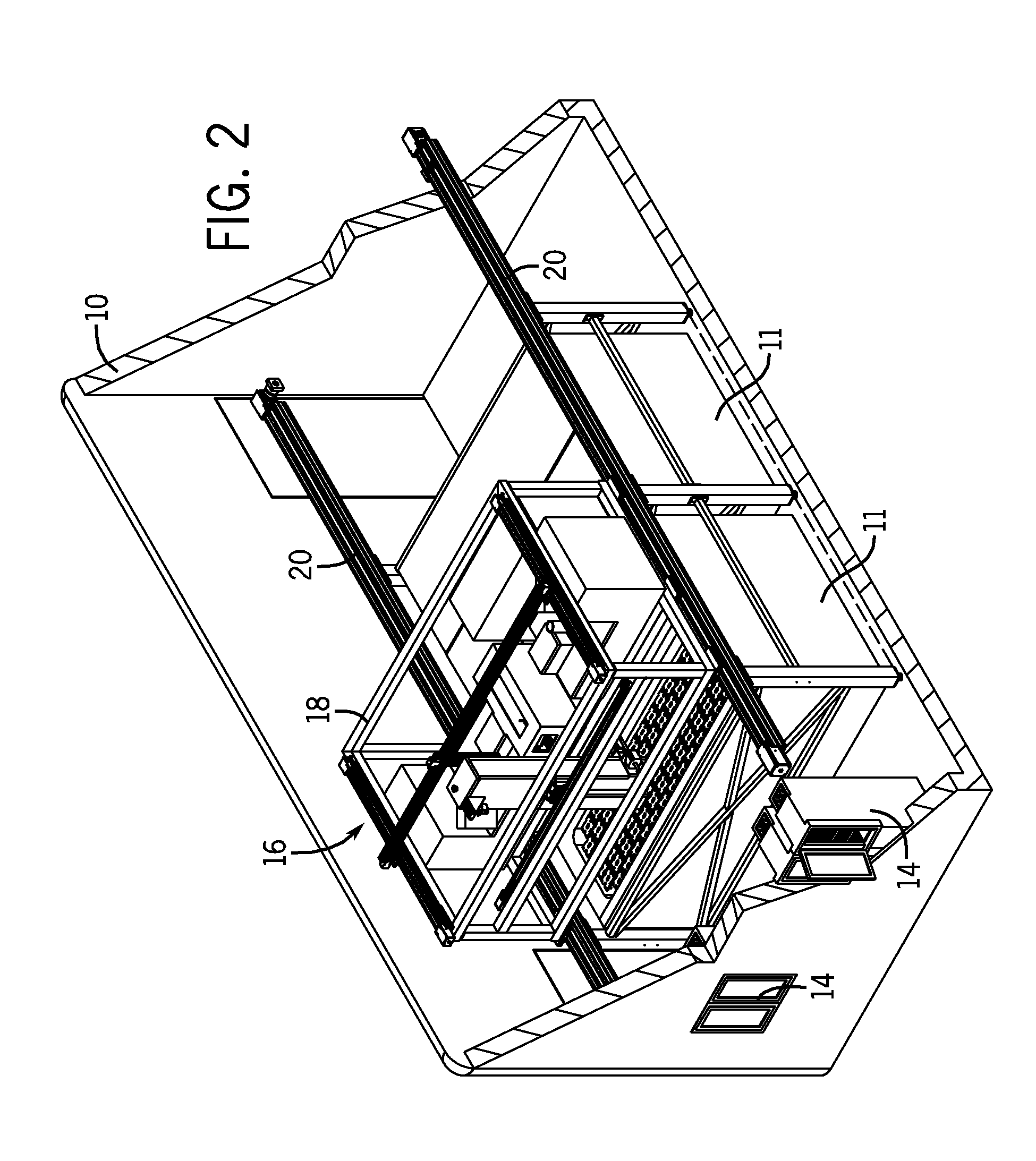

[0040]Referring to FIGS. 1 and 2, FIG. 1 illustrates the outside of a refrigerated enclosure 10 maintained at a temperature of approximately −15° C. to −30° C., preferably about −20° C.; and FIG. 2 illustrates inside the refrigerated enclosure 10. Two sample input / output modules 14 are located in the wall of the refrigerated enclosure 10. Multiple horizontal freezer chests 11 are located within the refrigerated enclosure 10, each including a storage compartment or freezer bay maintained at or below −65° C. under normal operating conditions. Preferably, each freezer chests 11 contains two independently cooled bays. Biological or chemical samples stored in sealed storage tubes held in tube racks or stored in sealed wellplates are stored within the freezer chests 11. In an ultra-low temperature system, the temperature within the freezer chests 11 will be maintained at for example −80° C. In a cryogenic system, the temperature within the chests 11 may be maintained at a temperature as l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com