Fluid conditioning arrangements

a technology of flue-condensing and heating arrangements, which is applied in the direction of lighting and heating apparatus, heating types, laminated elements, etc., can solve the problems of system requirements and low time temperature, and achieve the effect of reducing the number of components needed, improving energy usage effectiveness, and increasing the effective volum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

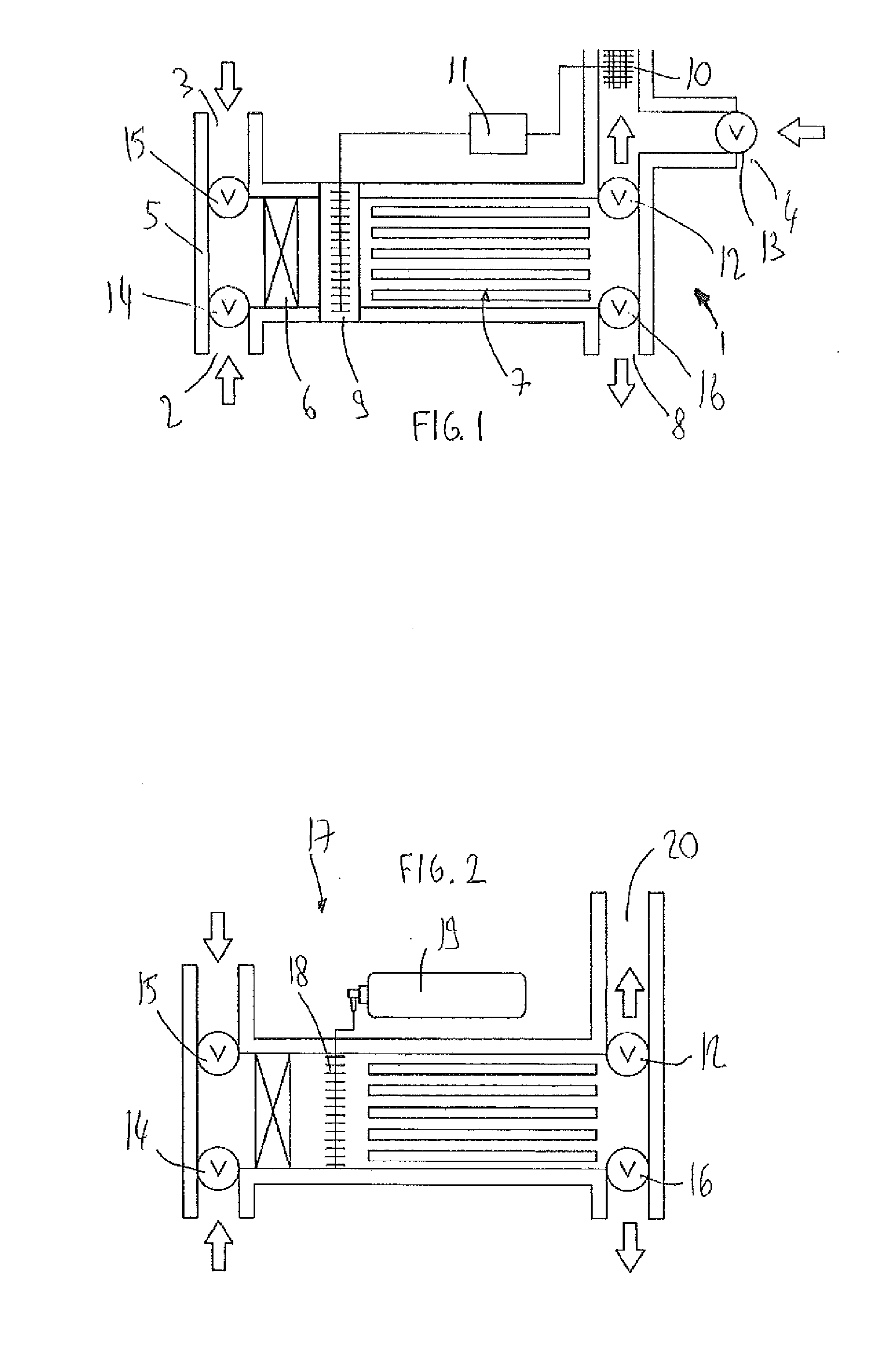

[0101]FIG. 1 shows a fluid conditioning arrangement generally referenced 1. The air conditioning arrangement 1 incorporates three air inlets respectively referenced 2, 3 and 4. Through inlet 3 fresh air from outside is drawn into the housing 5 by a fan or pump 6. It is important to note that whilst the embodiments of the invention are primarily illustrated for cooling air, other fluids may also be cooled and / or heated using these systems. In a conventional mode of operation the air is fed through a PCM heat exchanger 7 so that any heat in the air may be absorbed by the PCM before exiting the housing through outlet 8. The arrangement may preferably be equipped with a controller which may be configured to measure the temperature of the PCM in order to determine the extent of cooling that may be achieved by the heat exchanger. If due to the conditions surrounding the heat exchanger, a booster is required, as for example, the PCM heat exchanger fails to be effective or the incoming flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com