Particulate matter detection sensor and control device of controlling the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

[0045]A description will be given of a particulate matter detection sensor 1 and a control circuit 2 as a control device according to an embodiment of the present invention with reference to FIG. 1 to FIG. 6A, FIG. 6B and FIG. 6C.

[0046]The embodiment applies the particulate matter detection sensor 1 (hereinafter, referred to the “PM detection sensor 1”) to an exhaust gas purifying system of an internal combustion engine.

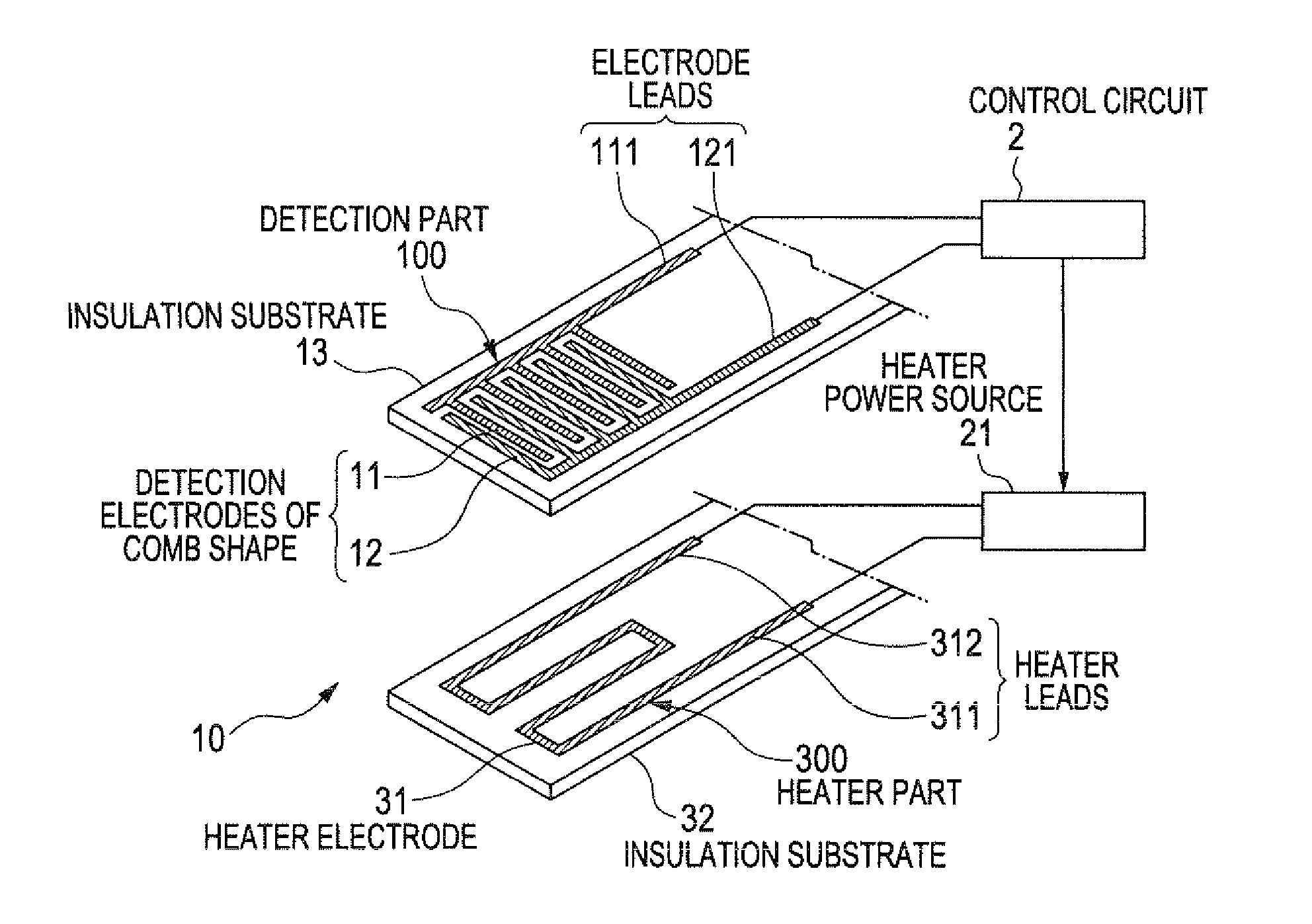

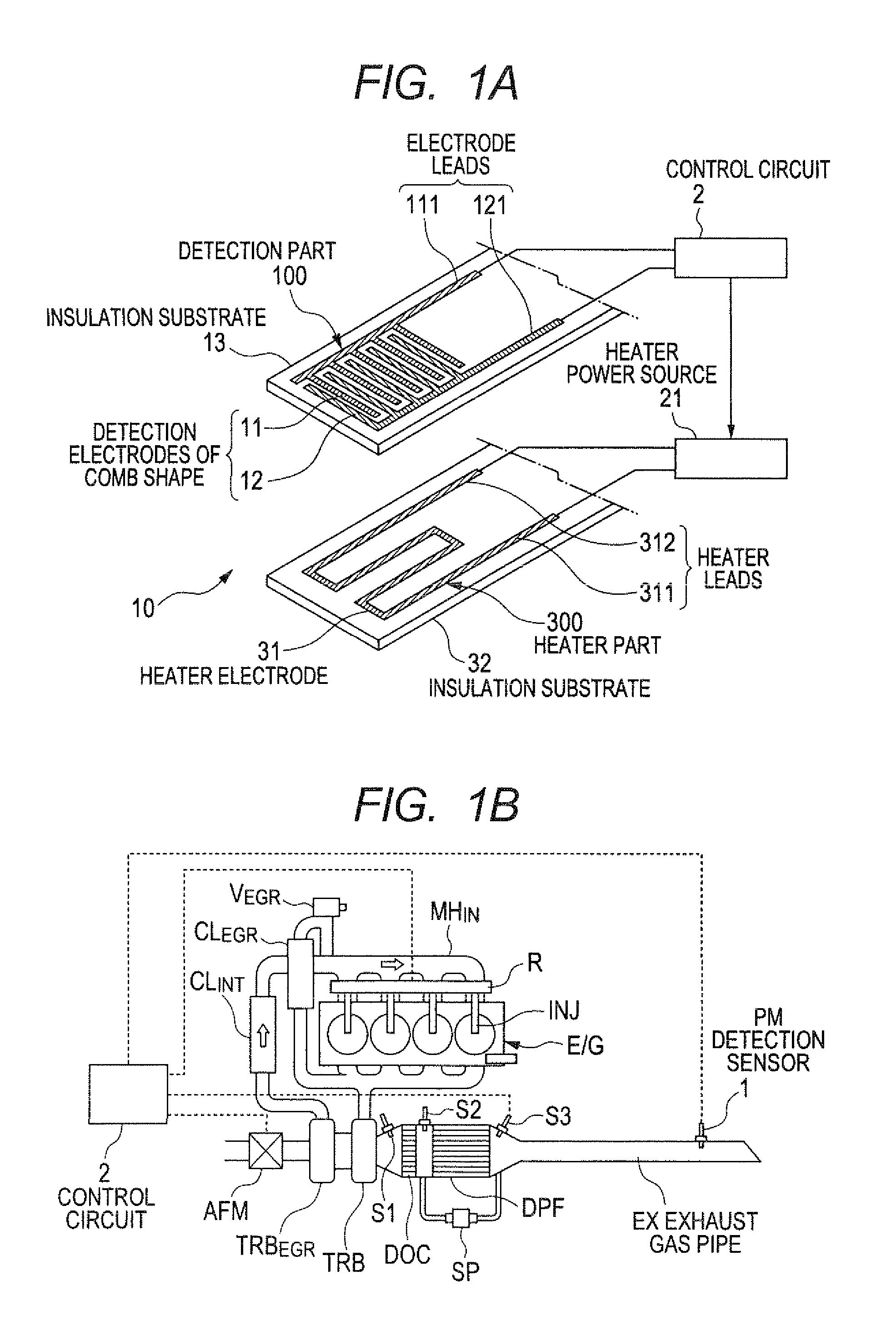

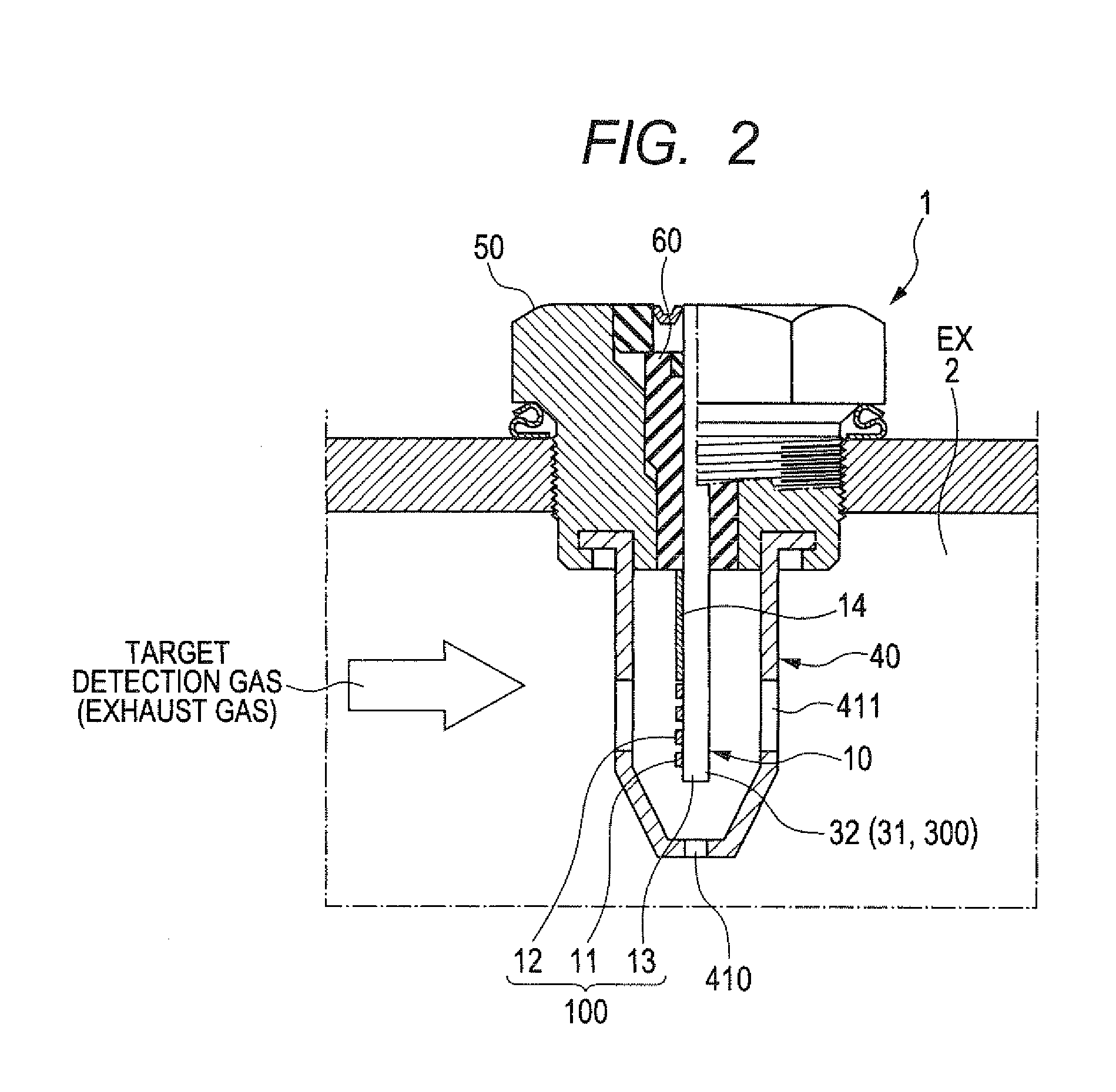

[0047]FIG. 1A is a perspective view showing a schematic structure of a particulate matter sensor element 10 (hereinafter, referred to the “PM sensor element 10”) in the PM detection sensor 1 and the control device 2 according to the embodiment of the present invention. FIG. 1B is a schematic view showing an entire configuration of the exhaust gas purifying system of an on-vehicle diesel engine of an motor vehicle to which the PM detection sensor 1 and the control device 2 according to the embodiment of the present invention are applied. FIG. 2 is an enlarged view sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com