Heat Dissipation Module

a heat dissipation module and heat dissipation technology, applied in the direction of lighting and heating apparatus, basic electric elements, semiconductor devices, etc., can solve the problems of high heat dissipation density, high temperature of electronic parts, and high heat generation of electronic parts, so as to achieve thin and lighter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

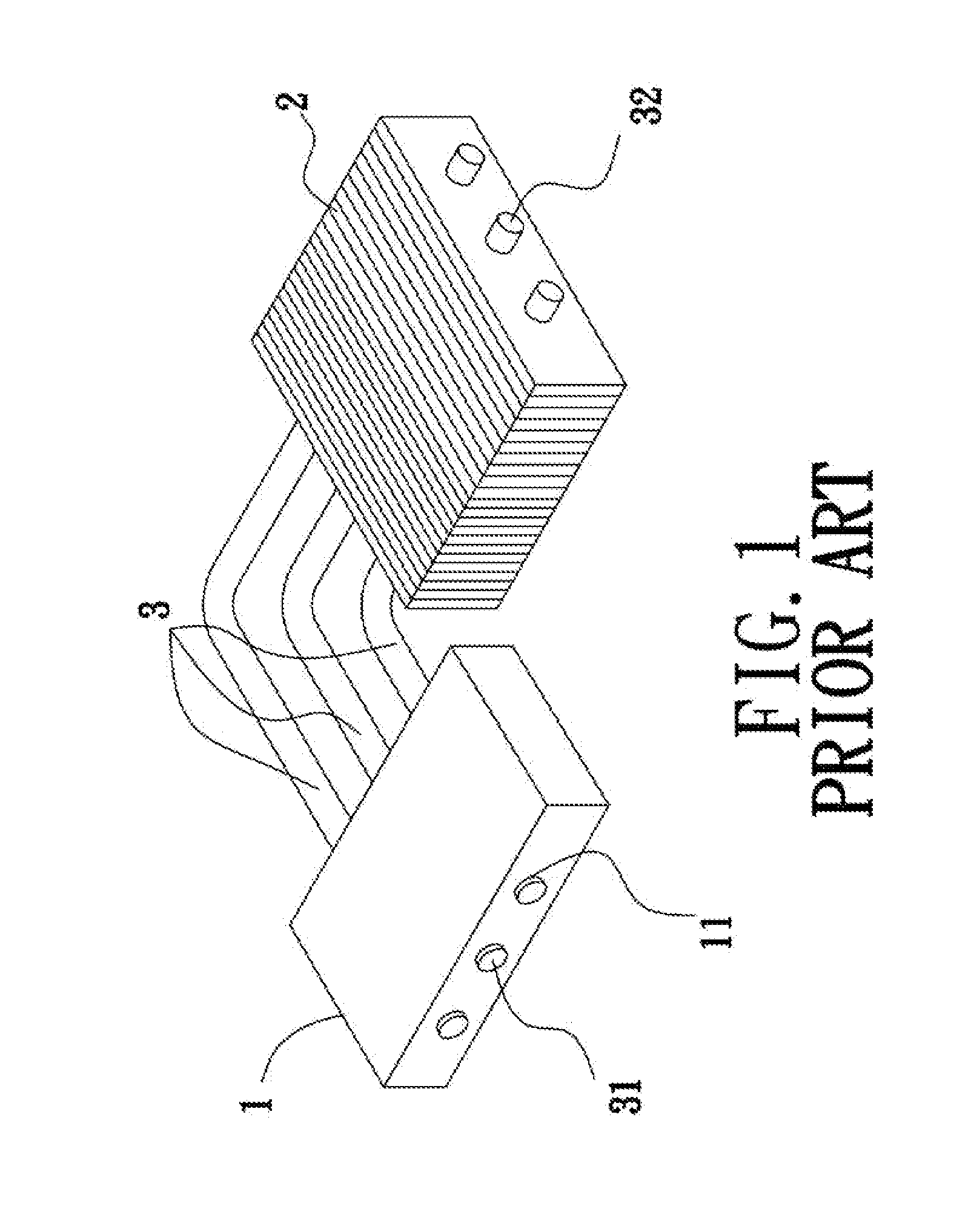

Image

Examples

Embodiment Construction

[0017]The foregoing object, structure, and function of the present invention are hereinafter described with reference to its preferred embodiment as shown in FIGS. 3 and 4.

[0018]Referring to FIGS. 3 and 4, a heat dissipation module according to the preferred embodiment of the present invention includes a cooling base 20 and at least one heat pipe 30. The cooling base 20 includes a heating surface 201 and a conducting surface 202 on the opposite side thereof. On the cooling base 20 is disposed at least one joining part 203, which can be in the form of a slot. At least one side thereof is designed as a flat surface 204. The said heating surface 201 is tightly attached to a heating component C (for example a CPU) to dissipate the heat generated by the said heating component C by absorbing and conducting it to heat pipe 30.

[0019]The said heat pipe 30 includes a heat dissipating end 310 and a heat absorbing end 320 thereon at least one flat surface 321 is formed. The said flat surface 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com