Electroformed bipolar plates for fuel cells

a fuel cell and bipolar plate technology, applied in the field of bipolar plate assembly, can solve the problems of reducing the service life of the fuel cell, so as to improve the service life and reduce the cost. the effect of cost, efficient and robust structure and optimized electrical conta

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The following detailed description and appended drawings describe and illustrate various embodiments of the invention. The description and drawings serve to enable one skilled in the art to make and use the invention, and are not intended to limit the scope of the invention in any manner. In respect of the methods disclosed, the steps presented are exemplary in nature, and thus, the order of the steps is not necessary or critical.

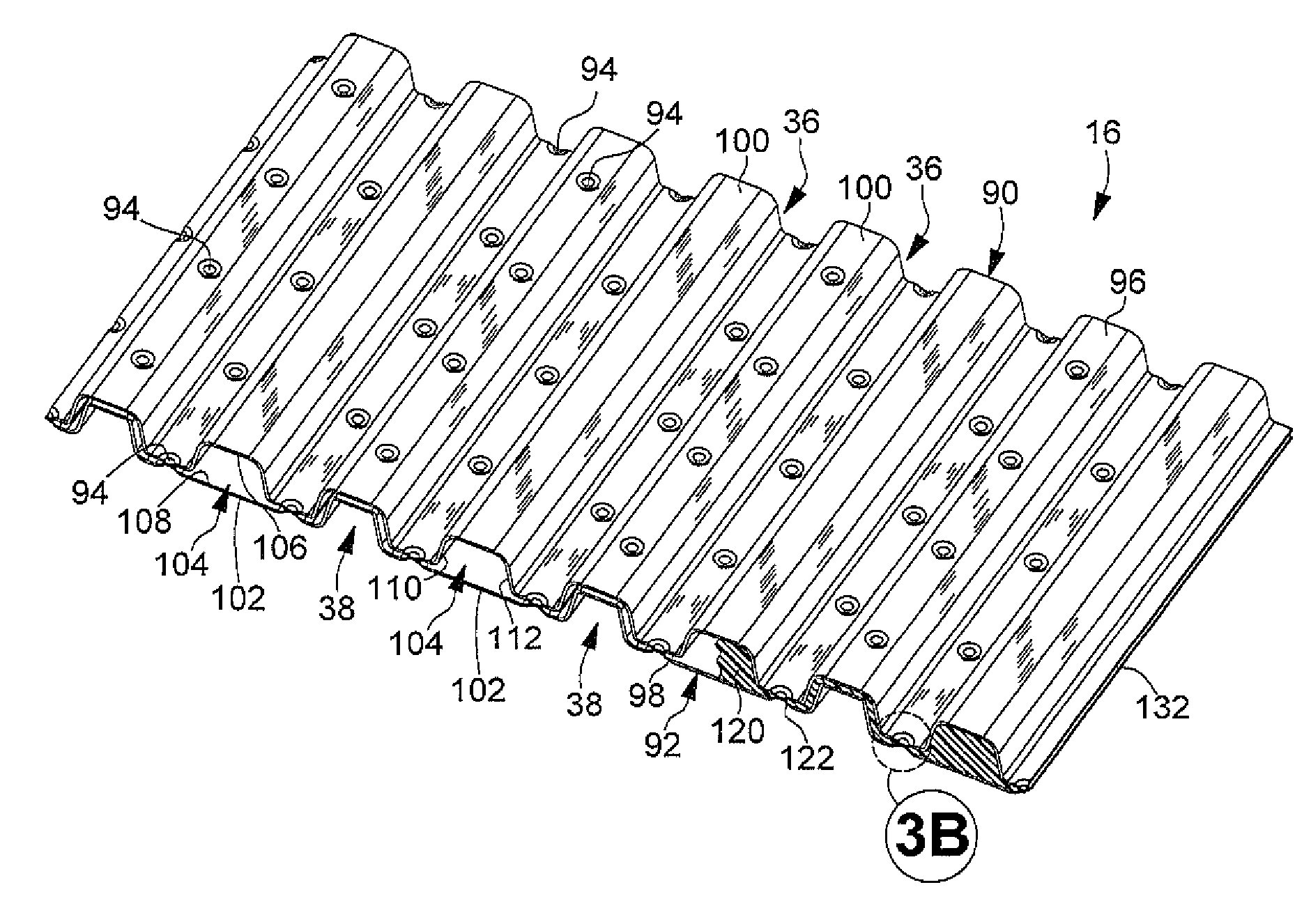

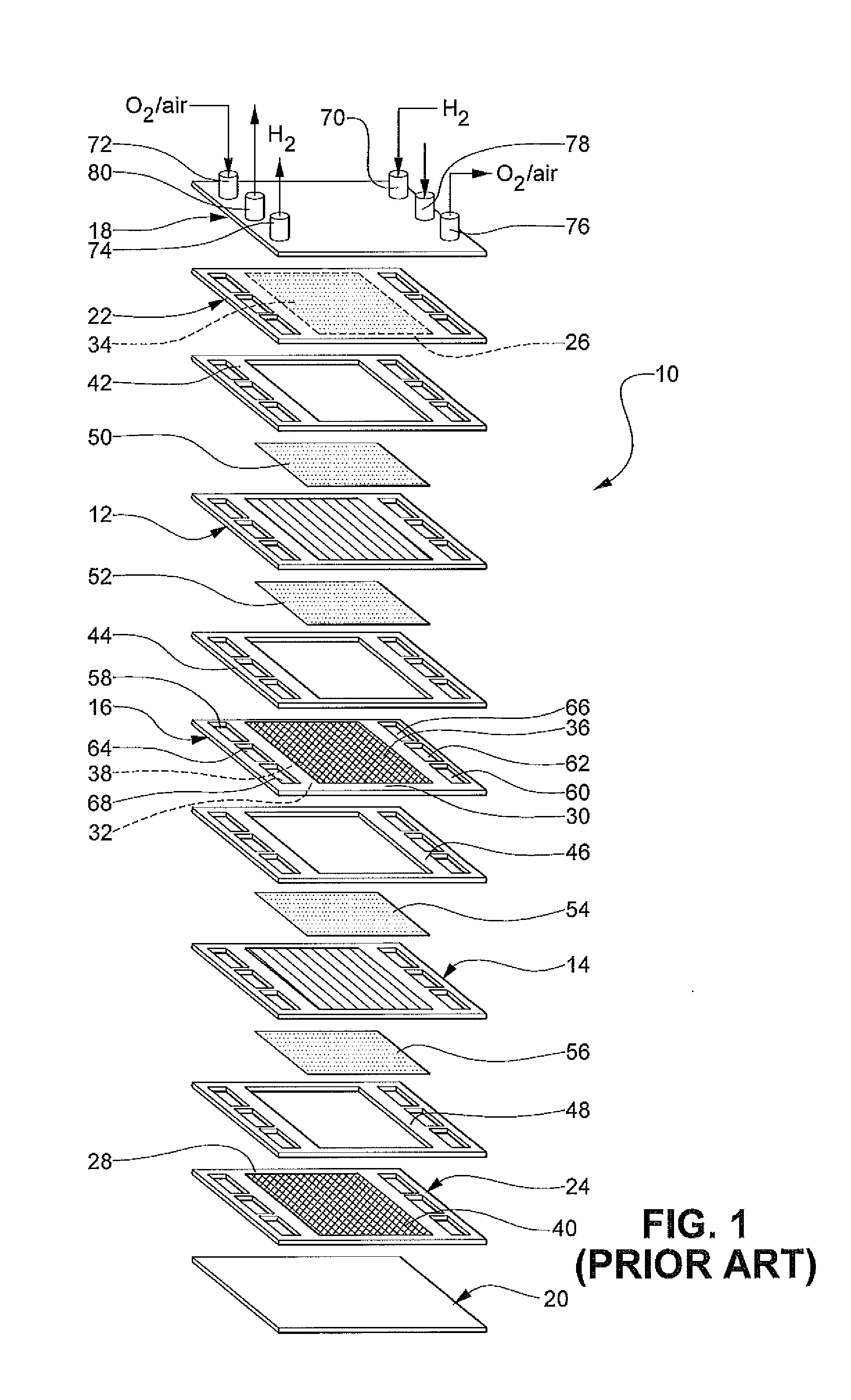

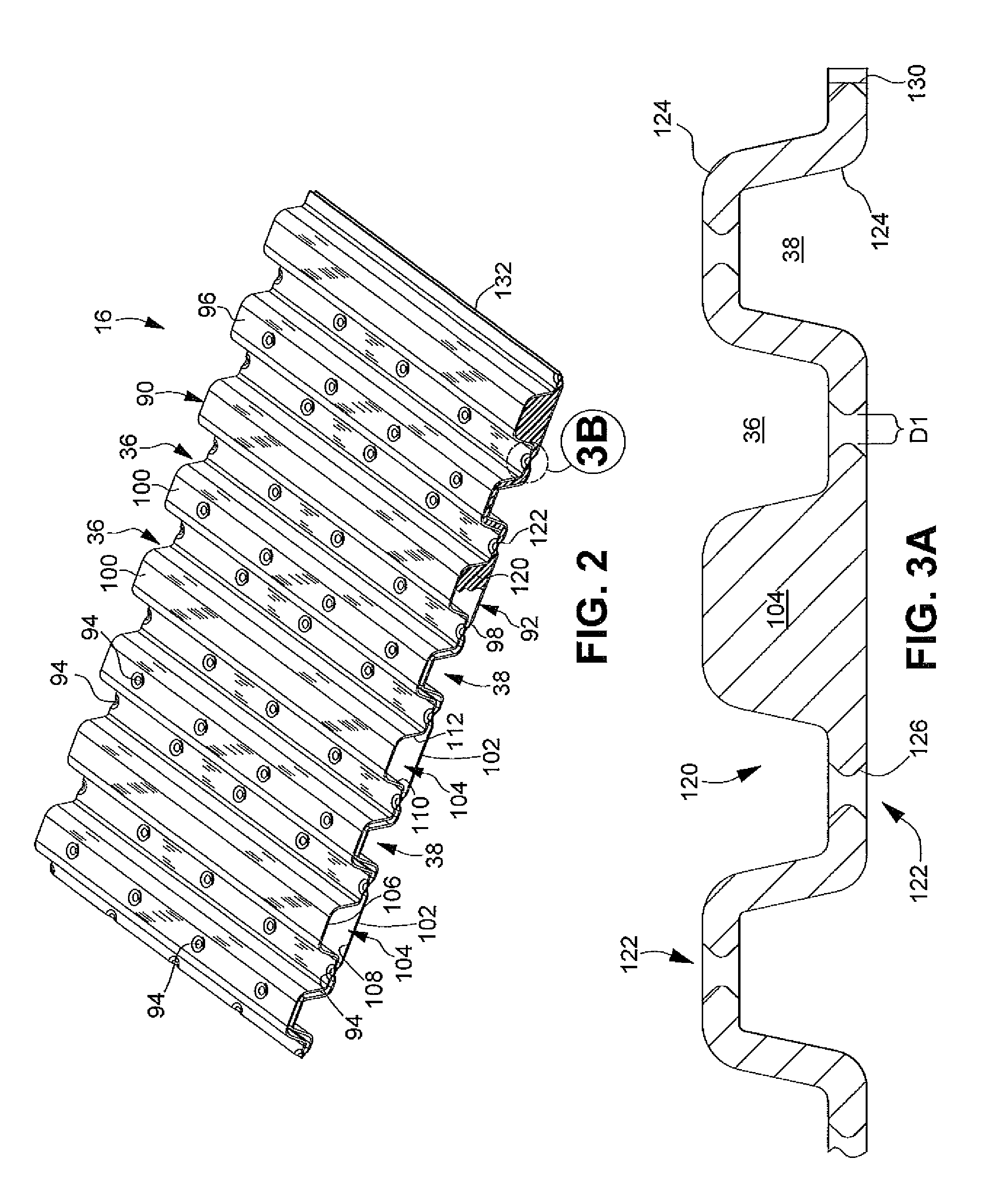

[0023]FIG. 1 illustrates a PEM fuel cell stack 10 according to the prior art. For simplicity, only a two-cell stack (i.e. one bipolar plate) is illustrated and described in FIG. 1, it being understood that a typical fuel cell stack will have many more such cells and bipolar plates. The fuel cell stack 10 includes a pair of membrane electrode assemblies (MEAs) 12, 14 separated by an electrically conductive bipolar plate 16. The MEAs 12, 14 and the bipolar plate 16 are stacked between a pair of clamping plates 18, 20 and a pair of unipolar end plates 22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com