Showerhead assembly with metrology port purge

a technology of metrology port and shower head, which is applied in the direction of chemically reactive gas, crystal growth process, coating, etc., can solve the problems of affecting the accurate measurement and control of the conditions within the processing zone, the deposition of precursor materials on the hot surface can be particularly problematic, and the break-down of precursor materials on the hot surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

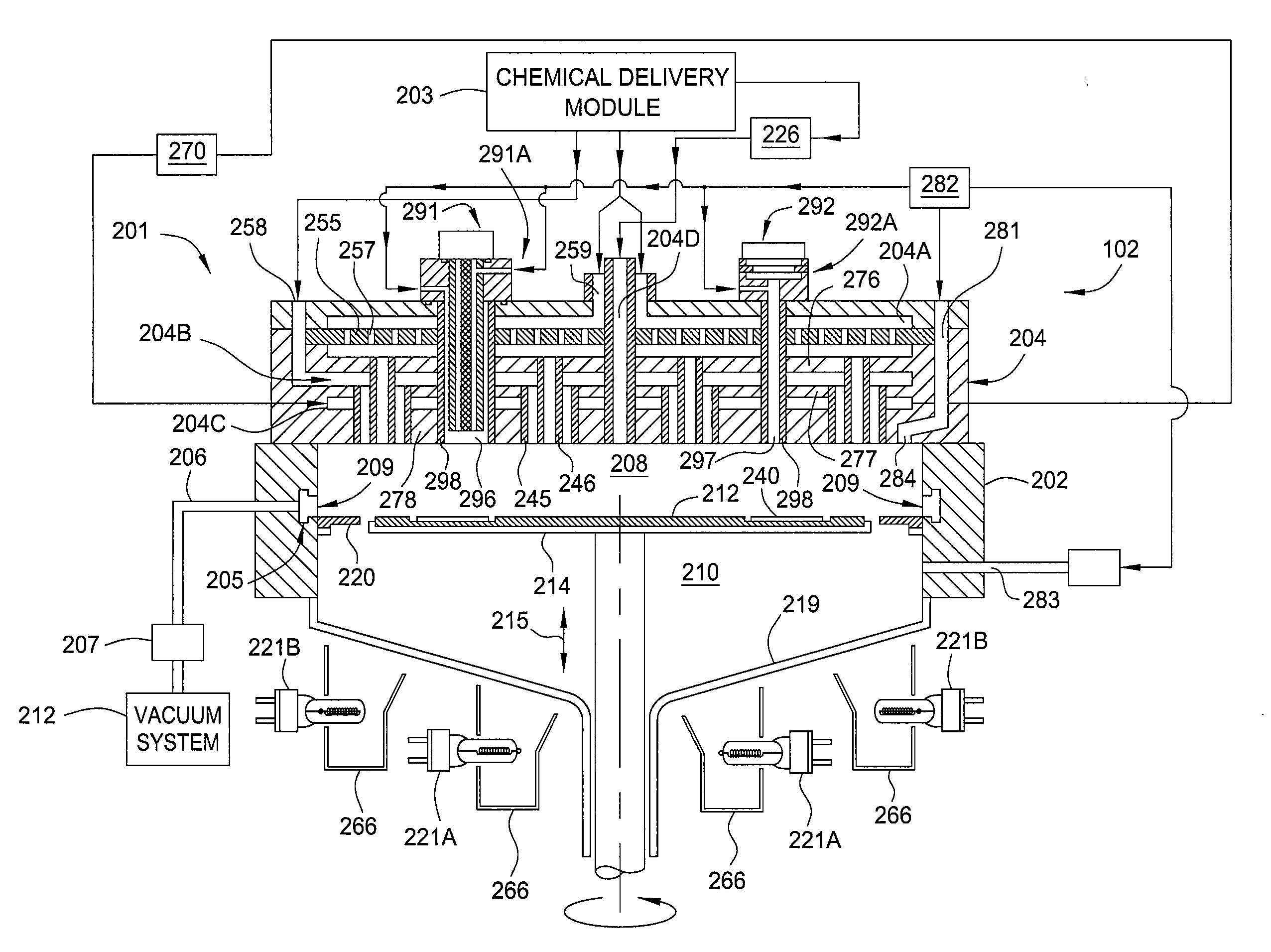

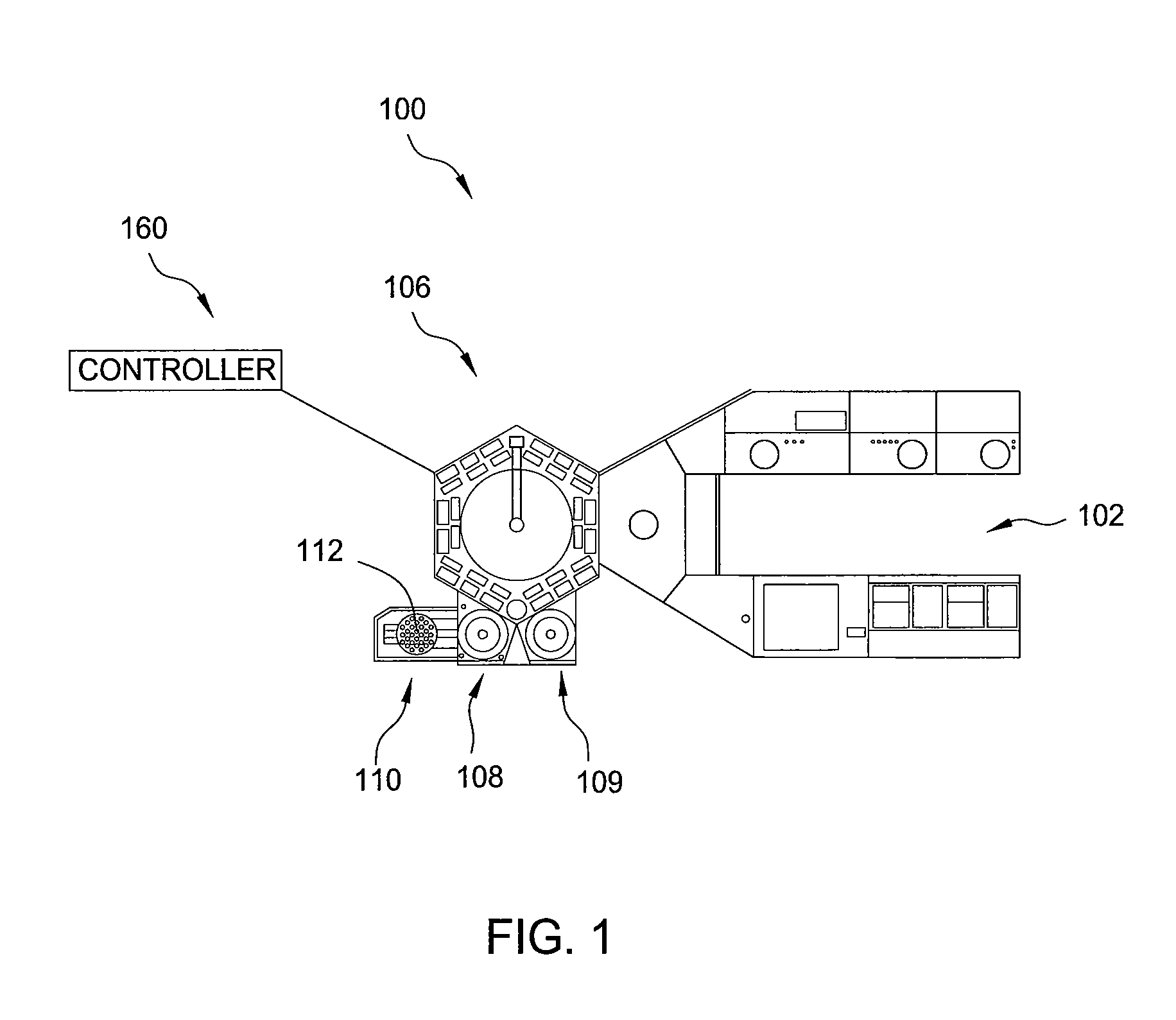

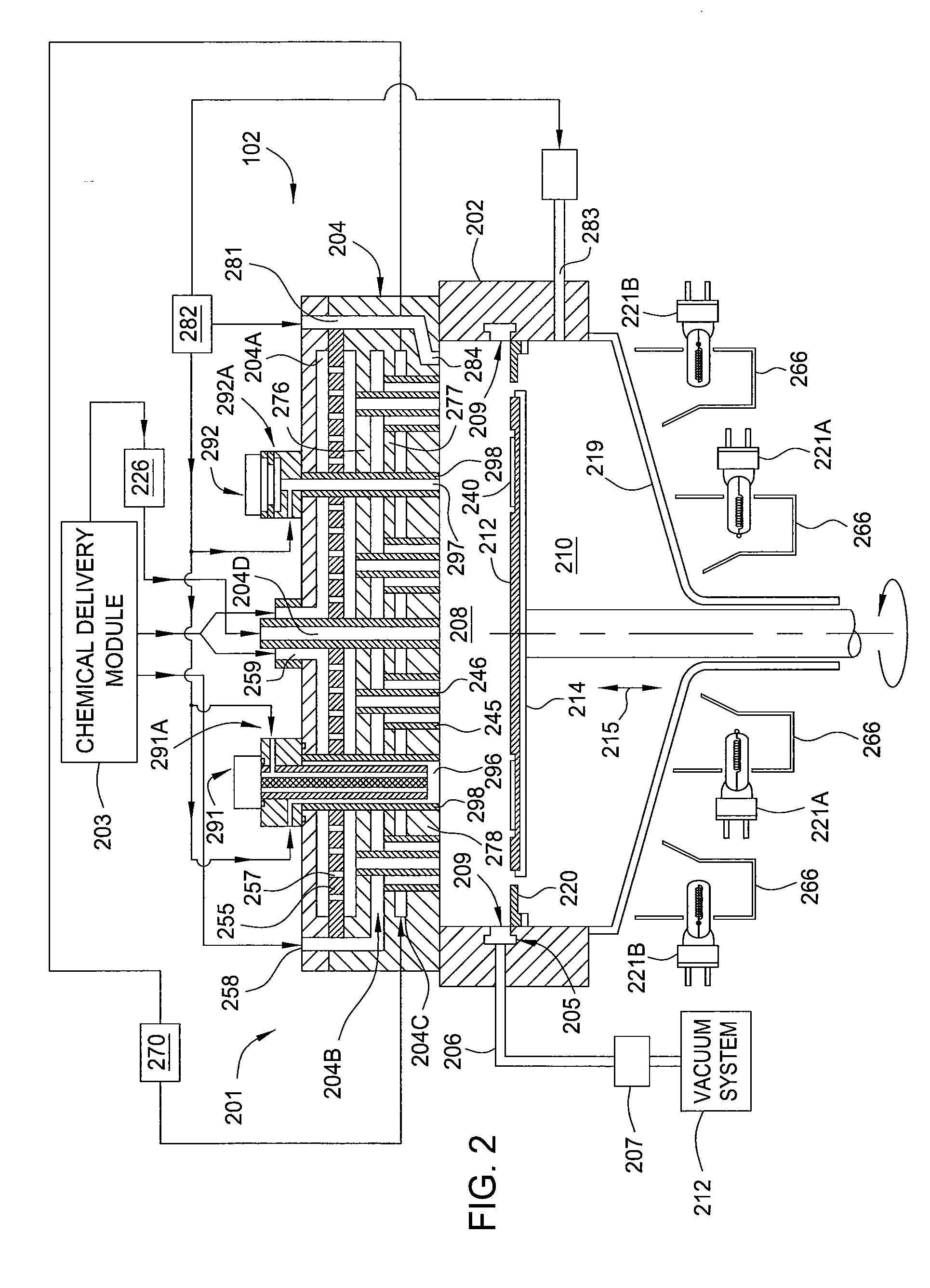

Embodiments of the present invention generally provide a method and apparatus that may be utilized for deposition of Group III-nitride films using MOCVD and / or HVPE hardware. In one embodiment, the apparatus is a processing chamber that includes a showerhead with separate inlets and channels for delivering separate processing gases into a processing volume of the chamber without mixing the gases prior to entering the processing volume. In one embodiment, the showerhead includes metrology ports with purge gas assemblies configured and positioned to deliver a purge gas to prevent deposition thereon. In one embodiment, the metrology port is configured to receive a temperature measurement device, and the purge gas assembly is a concentric tube configuration configured to prevent deposition on components of the temperature measurement device. In one embodiment, the metrology port has a sensor window and is configured to receive an optical measurement device that is configured to deliver ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com