Ultra Low Phosphorus Lubricant Composition Incorporating Amine Tungstate

a technology of amine tungstate and lubricant composition, which is applied in the direction of additives, lubricant compositions, petroleum industry, etc., can solve the problems of affecting the performance of pollution control devices, vehicles emit high levels of pollution, and fail to meet the requirements of fuel economy, corrosion and wear protection, and corrosion resistance. good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

(1) Tungstate Salts

[0013](a) Amine Tungstates

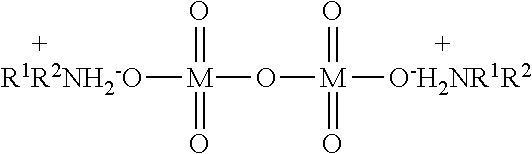

[0014]Amine tungstates are known to those skilled in the art. As non-limiting examples, U.S. Pat. No. 7,335,625 and U.S. Pat. No. 7,879,777, incorporated herein by reference, teach the reaction product of a metal acid hydrate of formula MO4H2.H2O with at least one alkyl amine, having the formula:

wherein M is tungsten; and R1 and R2 may be identical or different, and are selected from the group consisting of hydrogen, linear or branched, saturated or unsaturated C2-C40 alkyl, C3-C40 cycloalkyl, C6-C40 aryl, C7-C40 alkaryl and aralkyl. In a preferred embodiment, the products are a di-(C11-14-branched and linear alkyl) amine tungstate or a mono-succinimide tungstate.

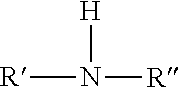

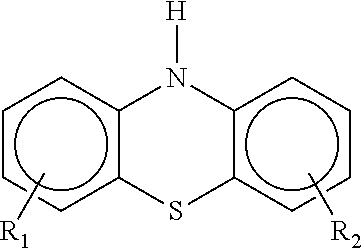

[0015]Additional amine tungstates are set forth in US Published Application No. 2008 / 0234154, incorporated herein by reference, which teaches an organic tungsten complex prepared by reacting[0016](a) an ammonium tungstate salt, wherein the tungstate salt is the reaction product o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com