MEMS device manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

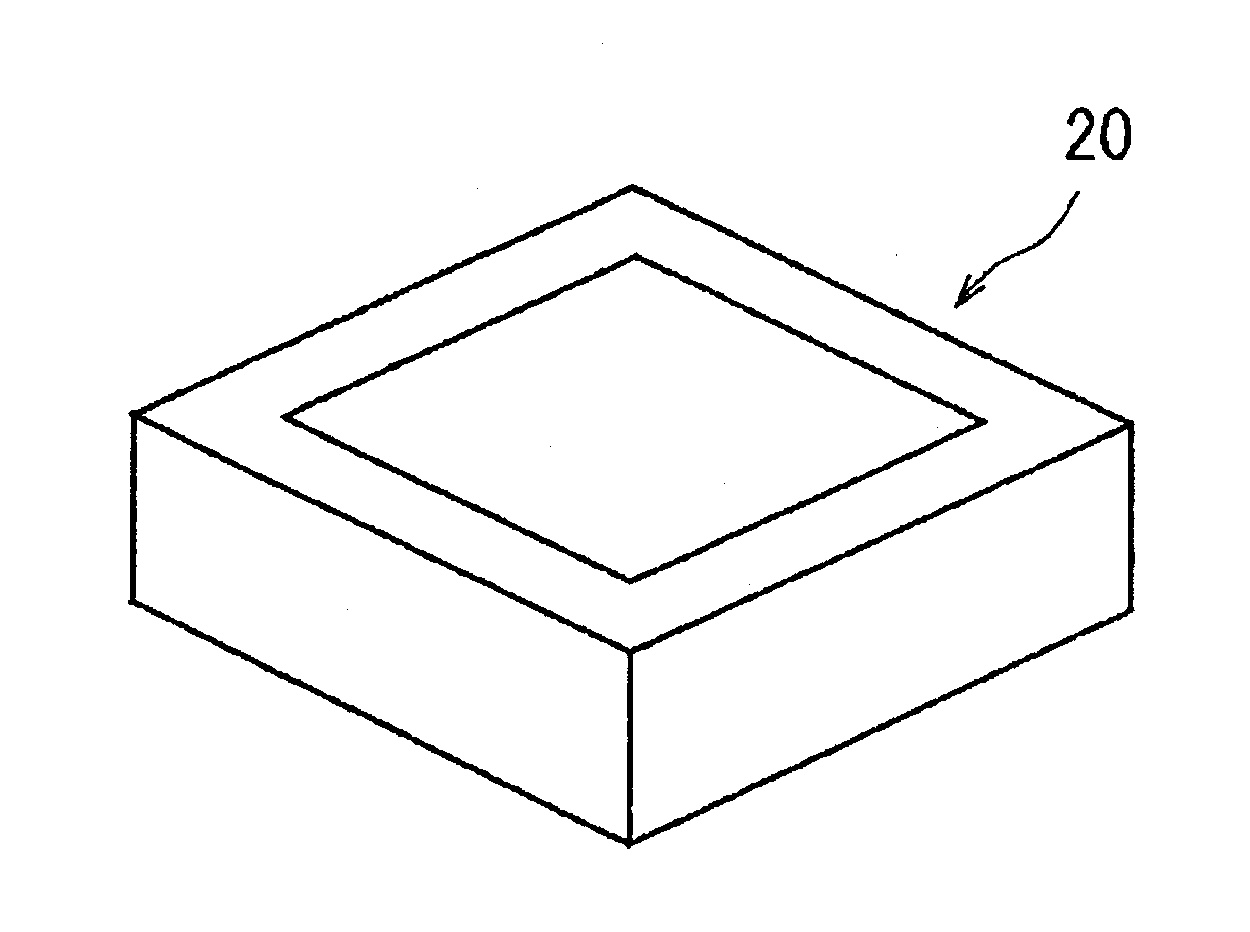

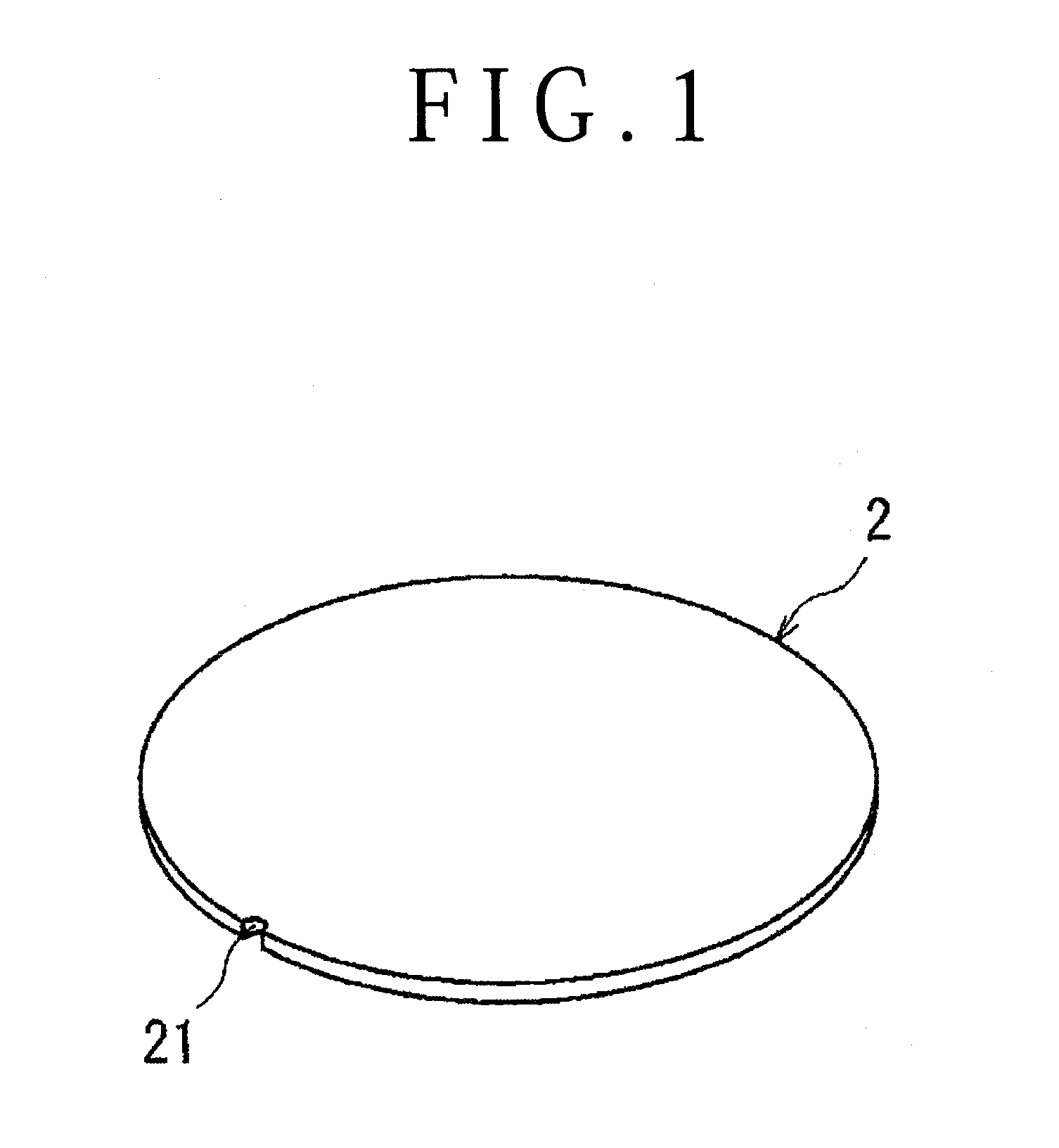

[0023]A preferred embodiment of the MEMS device manufacturing method according to the present invention will now be described in detail with reference to the attached drawings. FIG. 1 is a perspective view of a substrate 2 in the condition where a plurality of MEMS devices have not yet been formed thereon. The substrate 2 shown in FIG. 1 is formed from a glass substrate having a thickness of 200 μm, for example. The outer circumference of the substrate 2 is formed with a notch 21 for indicating a reference position. In manufacturing a plurality of MEMS devices by using the substrate 2 formed from a glass substrate shown in FIG. 1, a break start point forming step is first performed to form a break start point in the substrate 2 along the areas corresponding to a plurality of crossing streets set on the substrate 2 before forming a plurality of MEMS devices on the substrate 2.

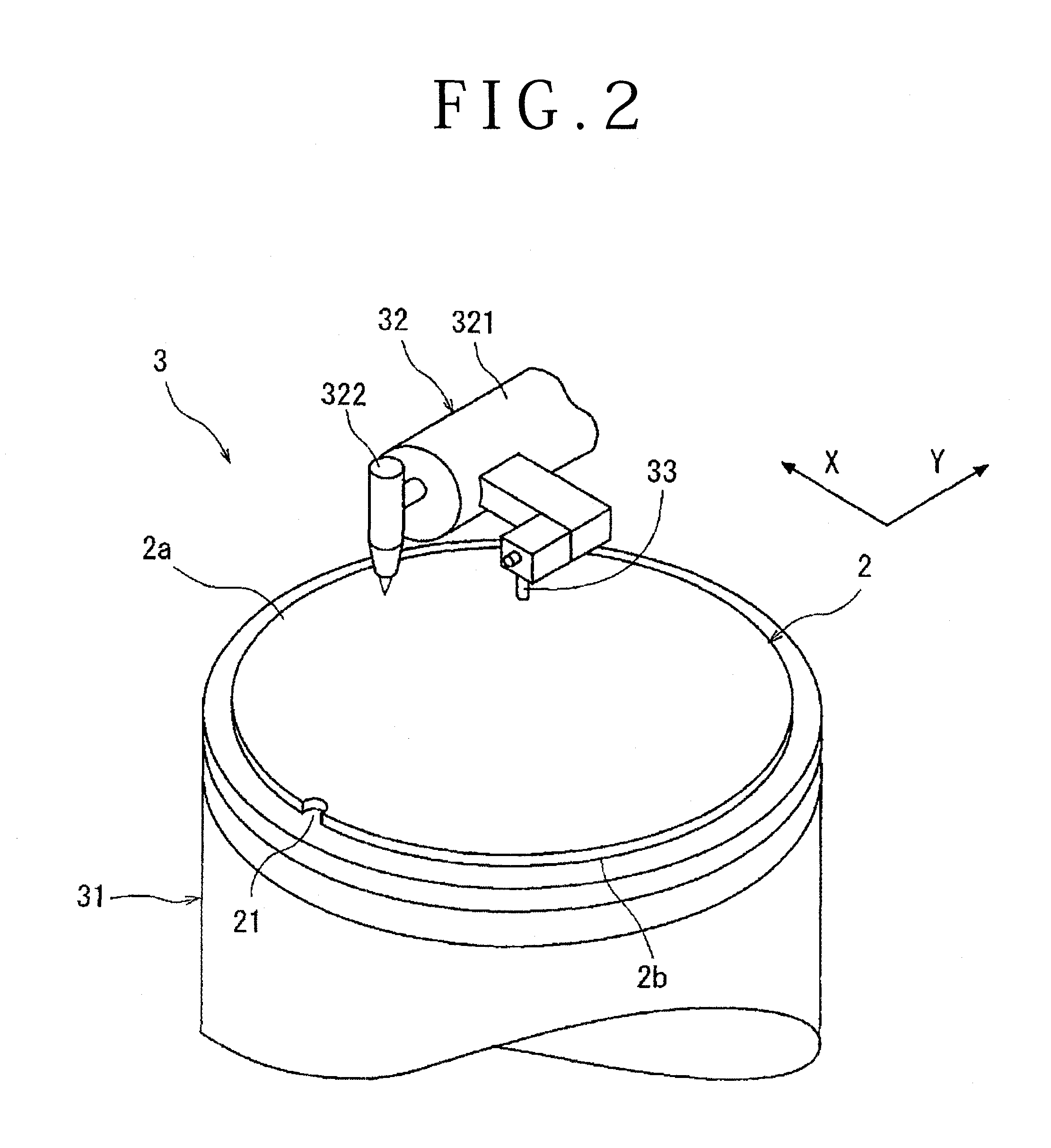

[0024]This break start point forming step is performed by using a laser processing apparatus 3 shown in FIG. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com