Evaporated fuel treatment apparatus and method of detecting failure in control valve

a technology of evaporation fuel treatment and control valve, which is applied in the direction of combustion air/fuel air treatment, electric control, instruments, etc., to achieve the effect of shortening the waiting tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0063]FIG. 4 shows a flowchart of an evaporated fuel treating method executed by the evaporated fuel treatment apparatus 1 according to the first embodiment of the present invention.

[0064]The control unit 2 starts (is activated) upon turning on of the IG (ignition) switch of the vehicle, etc., equipped with the evaporated fuel treatment apparatus 1.

[0065]The control unit 2 determines in step S1 whether or not the IG (ignition) switch is turned off. When the IG switch is turned off (step S1: YES), the flow of the process along this flowchart is terminated, and when the IG switch is not turned off (step S1: NO), the process progresses to step S3.

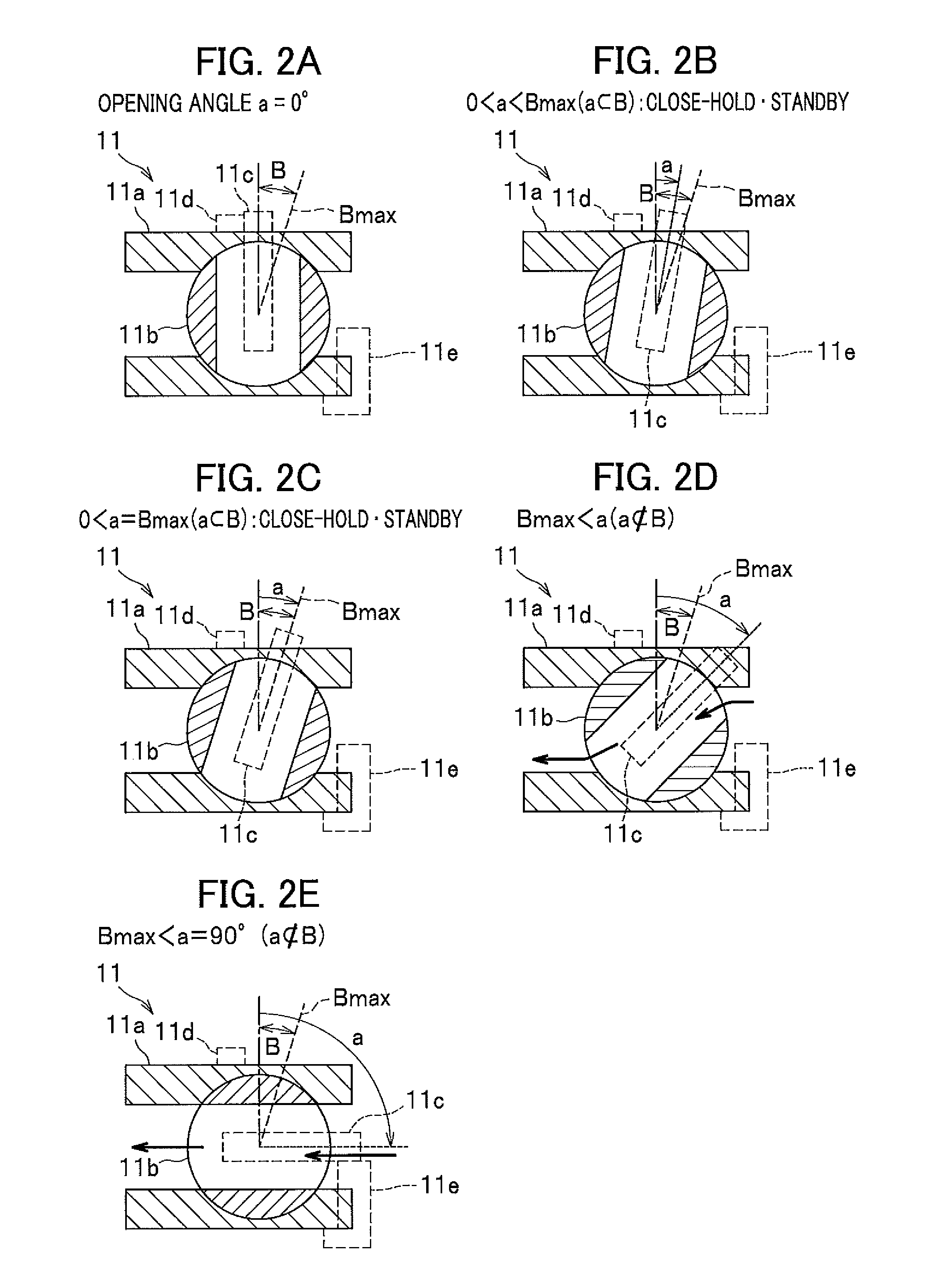

[0066]The control unit 2 executes zero point correction in step S2 in order to prevent the ball (the valve element) 11b from being seized. According to the zero point correction, the valve is closed until the stem 11c abuts the stopper 11d, etc., and the opening angle a at which the ball 11b is stopped is set as a zero point.

[0067]As shown in ...

second embodiment

[0088]FIG. 8 shows a flowchart of an evaporated fuel treating method executed by an evaporated fuel treatment apparatus 1 according to a second embodiment.

[0089]The control unit 2 is started (activated) upon turning on of the IG (ignition) switch of the vehicle, etc. equipped with the evaporated fuel treatment apparatus 1.

[0090]In step S201, the control unit 2 executes zero point correction which is also for preventing the ball (the valve element) 11b from being seized. According to the zero point correction, the valve is closed until the stem 11c abuts the stopper 11d, etc., and the opening angle a at which the ball 11b is stopped is set as the zero point. The opening angle a is changed within the dead-zone range B (the opening angle a is increased), and then the zero point correction (the opening angle a is decreased) is performed. The increase and decrease of the opening angle a prevents the ball (the valve element) 11b from being seized.

[0091]The control unit 2 determines in ste...

third embodiment

[0112]Next, an explanation will be given of a failure detecting method executed by an evaporated fuel treatment apparatus 1 according to a third embodiment of the present invention.

[0113]>

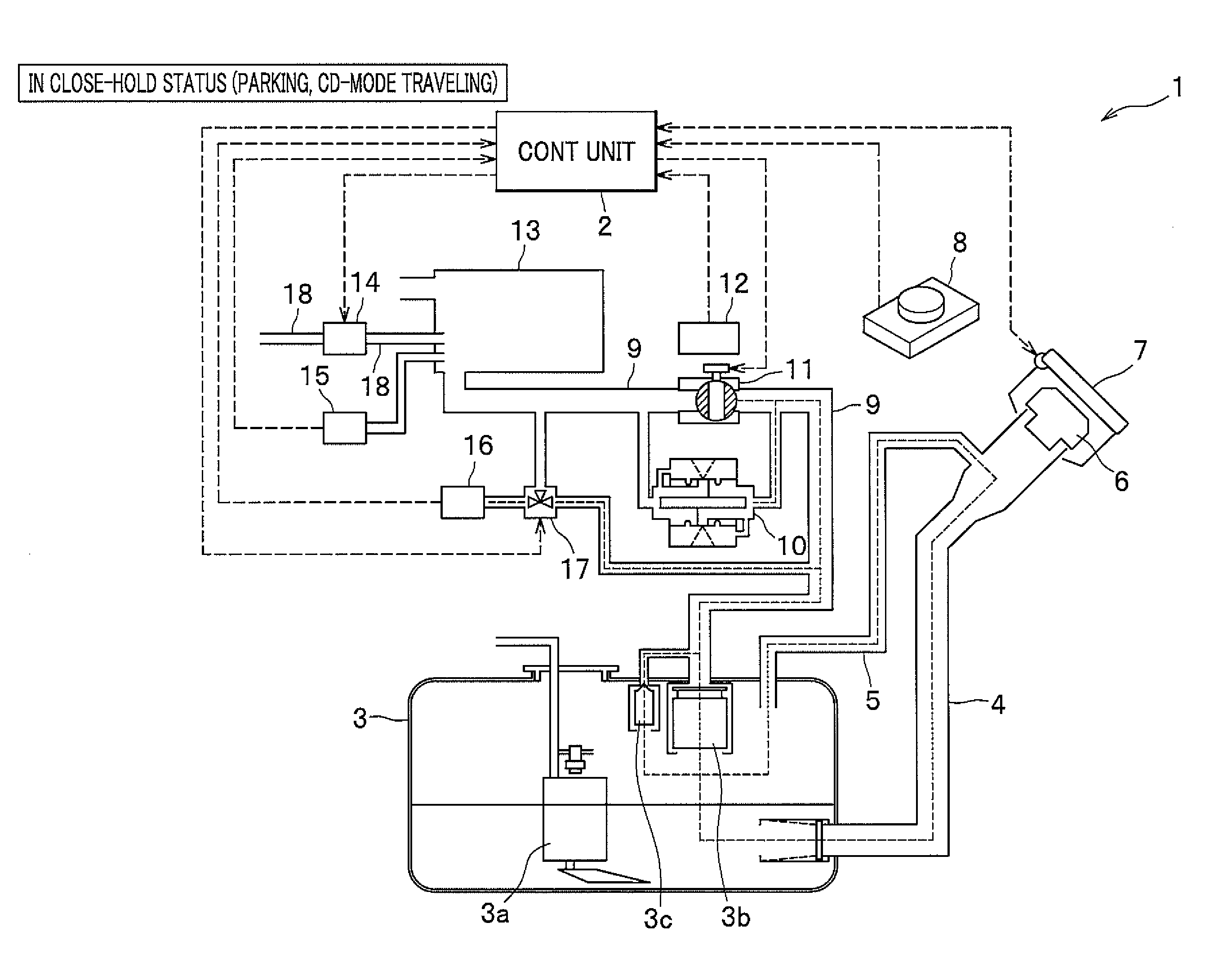

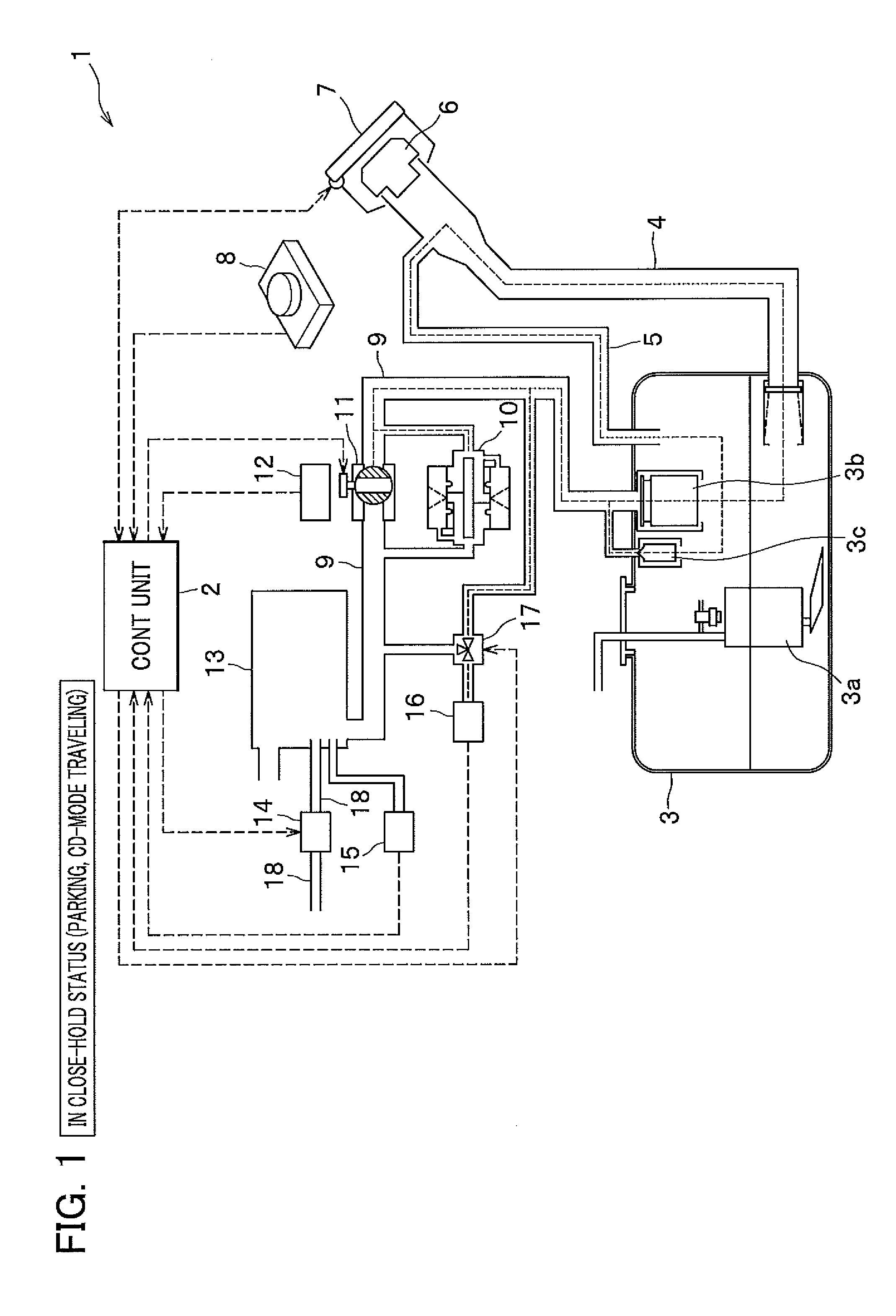

[0114]Vehicles such as plug-in hybrid vehicles which do not run the engine for a long time do not have the “CS MODE driving” (purging) status (see FIG. 7) and do not become the “fuel charging” status (see FIG. 6) if the fuel is not consumed. Accordingly, the status in which the control valve 11 is closed for a long time (see FIG. 1) is maintained, and thus the control valve 11 may be seized in some cases.

[0115]When the control valve 11 is seized, it is difficult to run the large amount of evaporated fuel (vapor) to flow into the canister 13 at the time of fuel charging (see FIG. 6), so that the evaporated fuel may leak from the fuel lid 7, and it is desirable to perform failure detecting control for detecting the seizing failure of the control valve 11.

[0116]Also, if the engine is not run, the evap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com