Exhaust system

a technology of exhaust system and exhaust pipe, which is applied in the direction of engine components, mechanical equipment, machines/engines, etc., can solve the problems of prolonging the service life of the entire exhaust system, and achieve the effect of reducing the tendency to development and allowing for greater freedom of design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

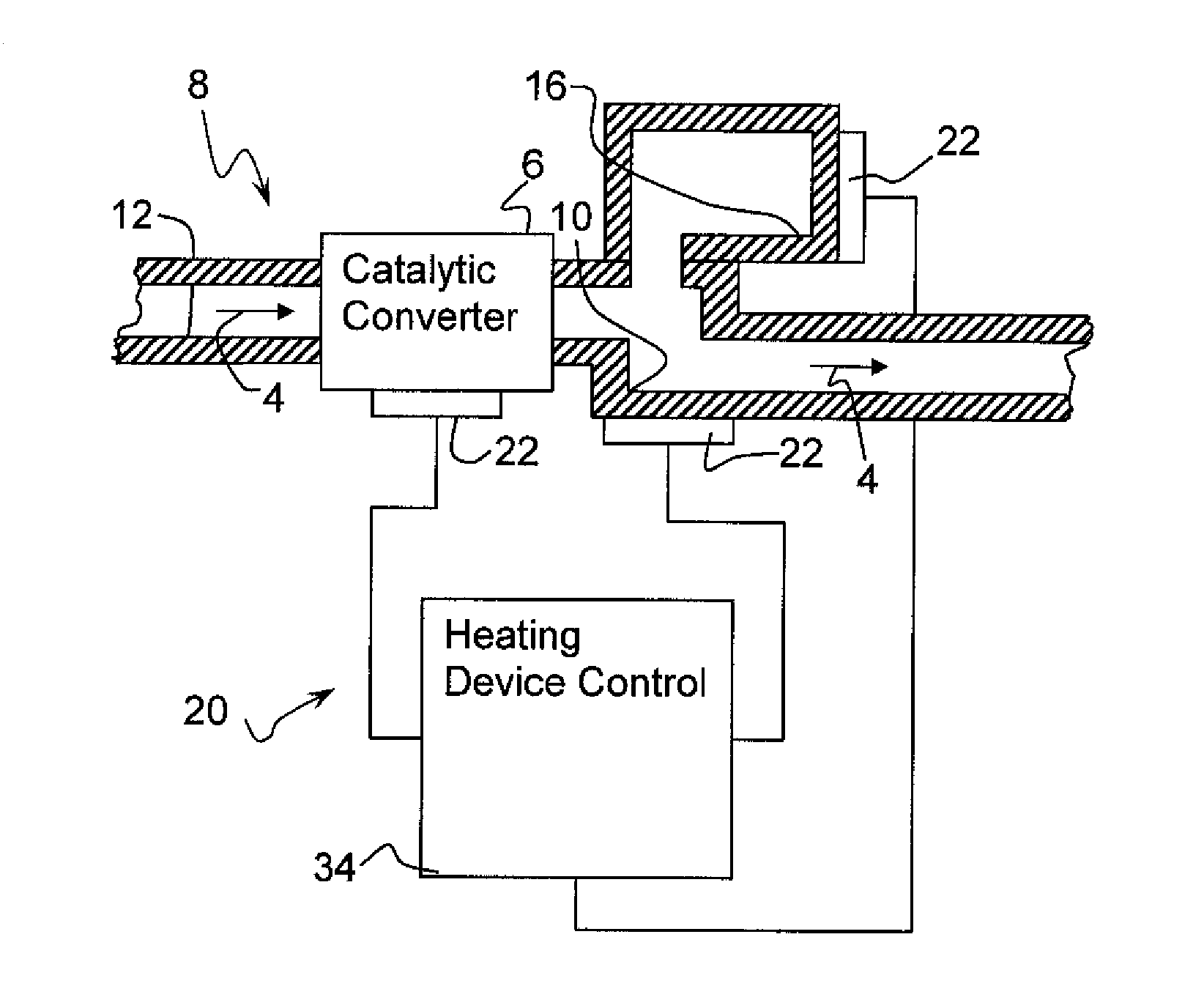

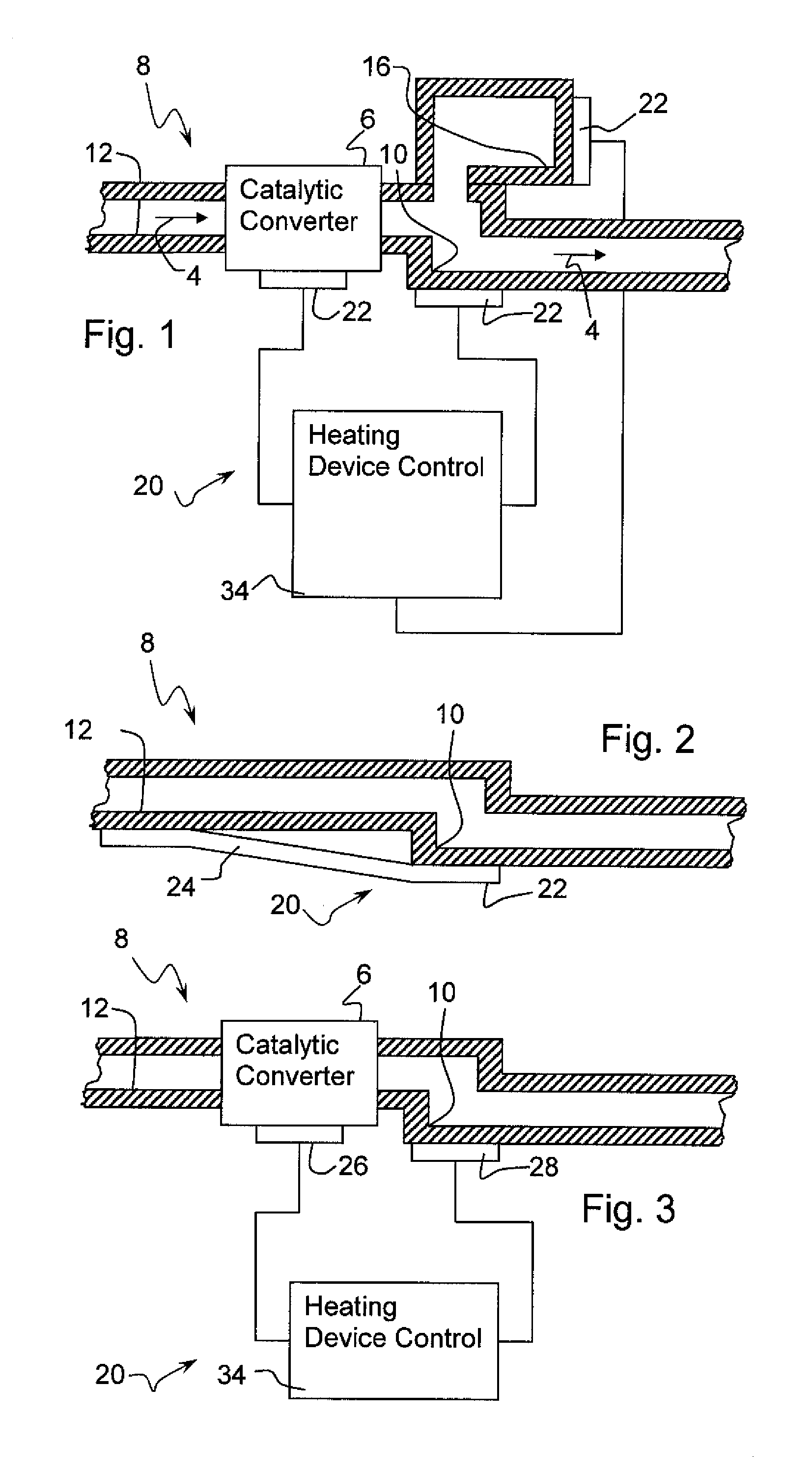

[0017]Referring to the drawings in particular, FIG. 1 schematically shows a section of an exhaust system 8 of a motor vehicle. The exhaust system 8 is shown with a flow passage, through which exhaust gas flows as indicated by arrows 4, having a wall with an exhaust system area 10 in which condensate accumulates and in which accumulation of condensate may take place depending on operating states and / or environmental parameters. The exhaust system 8 has a higher temperature area 12 which has a temperature higher than the temperature of the area 10 in which condensate accumulates to said area in which condensate accumulates.

[0018]A heating means 20 for the exhaust system may have a plurality of heating devices 22, which may be arranged in different positions at the exhaust system and which have different functionalities concerning the heating of the exhaust system. For example, a heating device 22 may thus be positioned in the area of a catalytic converter 6 arranged in the exhaust sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com