Phenolic foam

a technology of phenolic foam and cell walls, applied in the field of phenolic foam, can solve the problems of metals being susceptible to corrosion, reducing the flexibility of the cell walls of phenolic foam with time, and degrading thermal insulation performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

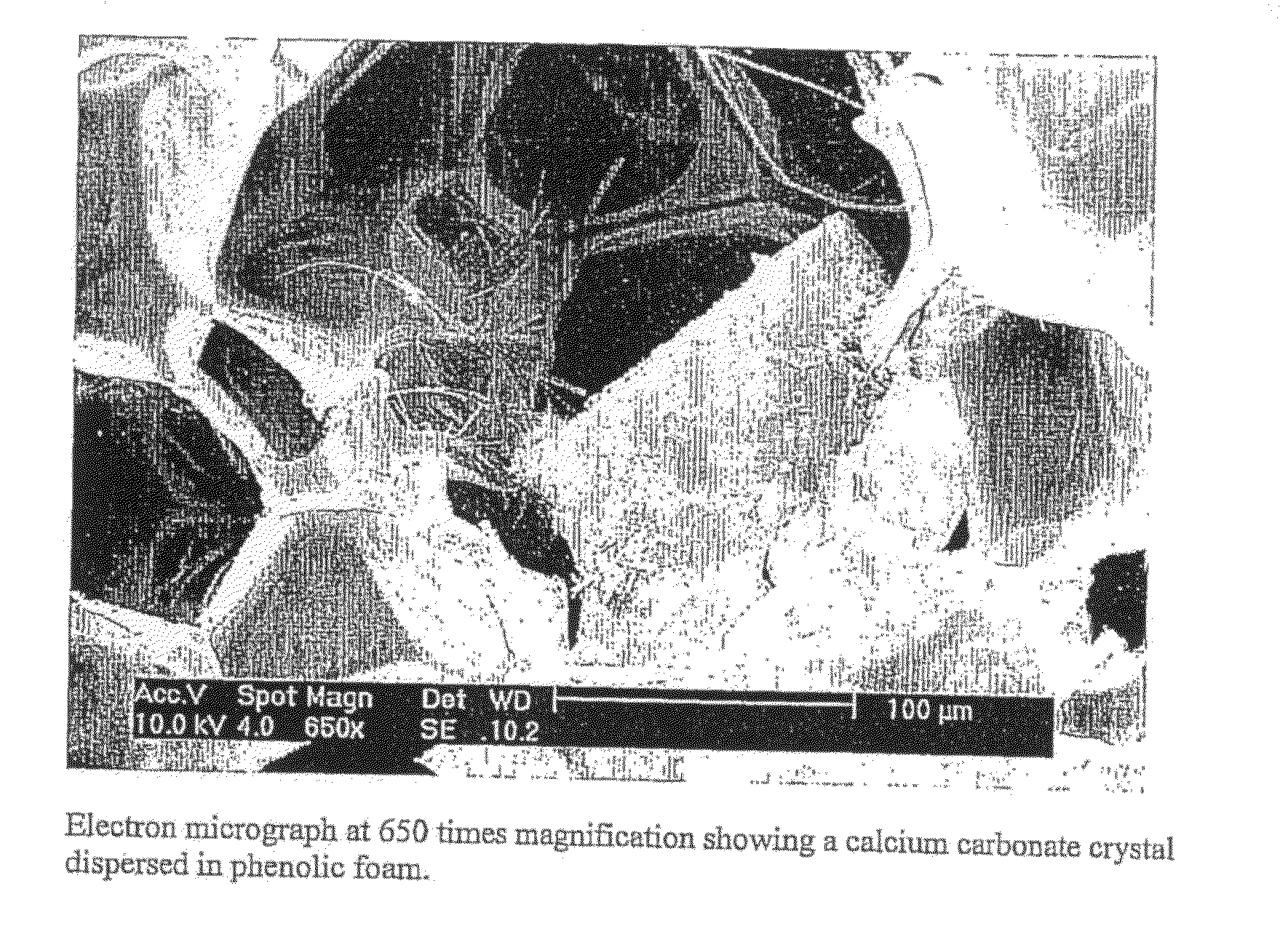

Image

Examples

example 1

[0098]To 244 g of Resin A, at 11-15° C., is mixed with 12.2 g of powdered urea and 6.1 g of a plasticiser as described previously herein. The resin is allowed to stand for between 2 and 24 hours. Then, 12.2 g of calcium carbonate powder (Durcal 130 supplied by Omya) of average particle size 170 μm is added and mixed into the resin until it is uniformly dispersed. Next, 21.0 g of pre-blended isopropyl chloride / iso-pentane (85 / 15 parts by weight) as blowing agent at 1° C. is mixed into the resin. Once a uniform emulsion has formed, the resin mixture is cooled to between 5° C. and 10° C. Next, 40 g of liquid para-toluene sulphonic acid / xylene sulphonic acid blend (65 / 35 parts by weight) at 92% concentration, at 8° C. is quickly mixed in. Foaming commences immediately. Mixing of the acid into resin takes less than 10 seconds and 200 g of the resin mix is quickly poured into a 30×30×5.0 cm picture frame mould preheated to 70-75° C.

[0099]A pressure of 40 to 50 kPa is applied to the lid of...

example 2

[0102]Here the ratio of isopropyl chloride to iso-pentane is adjusted to 70 / 30 parts per weight)

[0103]To 244 g of Resin A, at 11-15° C., is mixed with 12.2 g of powdered urea and 6.1 g of plasticizer as described previously herein. The resin is allowed to stand for between 2 and 24 hours. Then, 122 g of calcium carbonate powder (Durcal 130 supplied by Omya) is added and mixed into the resin until it is uniformly dispersed. Next, 21.0 g of pre-blended isopropyl chloride / iso-pentane (70 / 30 parts by weight) as blowing agent at 1° C. is mixed into the resin. Once a uniform emulsion has formed, the resin mixture is cooled to between 5° C. and 10° C. Next, 40 g of liquid para-toluene sulphonic acid / xylene sulphonic acid blend (65 / 35 parts by weight) at 92% concentration, at 8° C. is quickly mixed in. Foaming commences immediately. Mixing of the acid into resin takes less than 10 seconds and 200 g of the resin mix is quickly poured into a 30×30×5.0 cm picture frame mould preheated to 70-75...

example 3

[0106]Here there is a higher addition of plasticiser to the resin (12.2 g instead of 6.1 g).

[0107]To 244 g of Resin A, at 11-15° C., is mixed with 12.2 g of powdered urea and 12.2 g of plasticiser as described previously herein. The resin is allowed to stand for between 2 and 24 hours. Then, 12.2 g of calcium carbonate powder (Durcal 130 supplied by Omya) is added and mixed into the resin until it is uniformly dispersed. Next, 21.0 g of pre-blended isopropyl chloride / iso-pentane (85 / 15 parts by weight) as blowing agent at 1° C. is mixed into the resin. Once a uniform emulsion has formed, the resin mixture is Cooled to between 5° C. and 10° C. Next, 40 g of liquid para-toluene sulphonic acid / xylene sulphonic acid blend (65 / 35 parts by weight) at 92% concentration, at 8° C. is quickly mixed in. Foaming commences immediately. Mixing of the acid into resin takes less than 10 seconds and 200 g of the resin mix is quickly poured into a 30×30×5.0 cm picture frame mould preheated to 70-75° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com