Particulate Deflagration Enhanced Firebox

a firebox and enhanced technology, applied in the direction of machines/engines, combustion types, lighting and heating apparatus, etc., can solve the problems of not producing the discharge energy required, major damage to the engine, and not desirable detonation in the combustion engin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

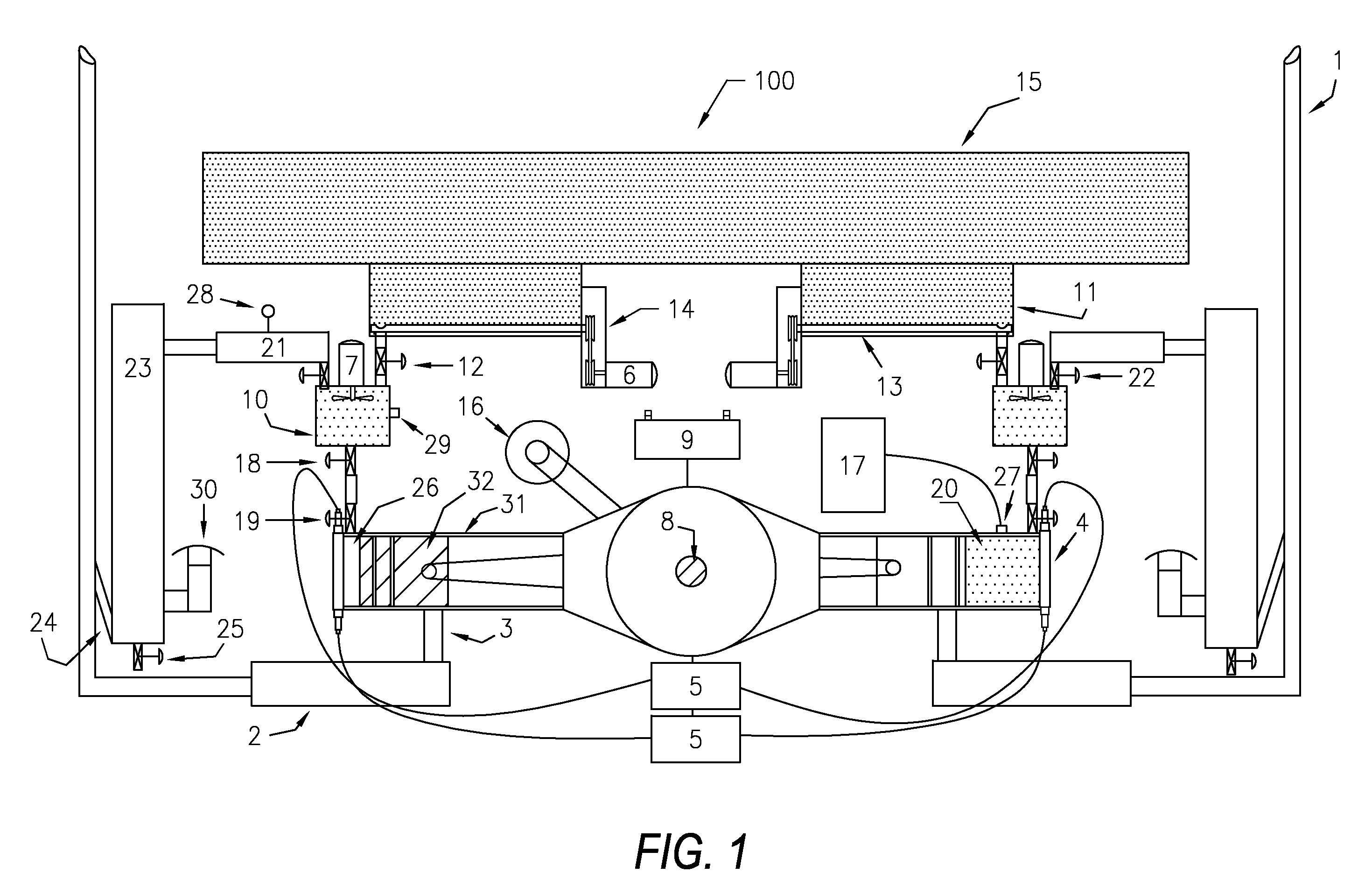

[0038]Referring now to FIG. 1, there is illustrated a particulate deflagration combustion engine 100 that is constructed in accordance with a preferred embodiment of the present invention. The fuel that is used in this engine 100 will need to have been previously reduced to the proper particle size by grinding or other suitable means and has passing it through sizing sieves to achieve the desired particle size range. A particle size of between 8-12 microns is preferred for this application to achieve proper burning in the engine 100. The previously prepared particulate fuel is put into the main fuel tank 15 of the engine 100 which is shown at the top of FIG. 1.

[0039]FIG. 1 is a diagram of the engine 100. For ease of illustration, FIG. 1 shows only two cylinders 31. However, the actual engine 100 is not limited to two cylinders 31. Also, the arrangement of the components of the actual engine 100 may be somewhat different than illustrated in FIG. 1 since the diagram is presented to il...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com