Low Mixing Ventilation Jet

a technology of low-mixing and ventilation jets, which is applied in ventilation systems, lighting and heating apparatus, heating types, etc., can solve the problems of large energy costs of volumetric flow, and achieve the effect of less expensive production and reduced jet mixing degr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

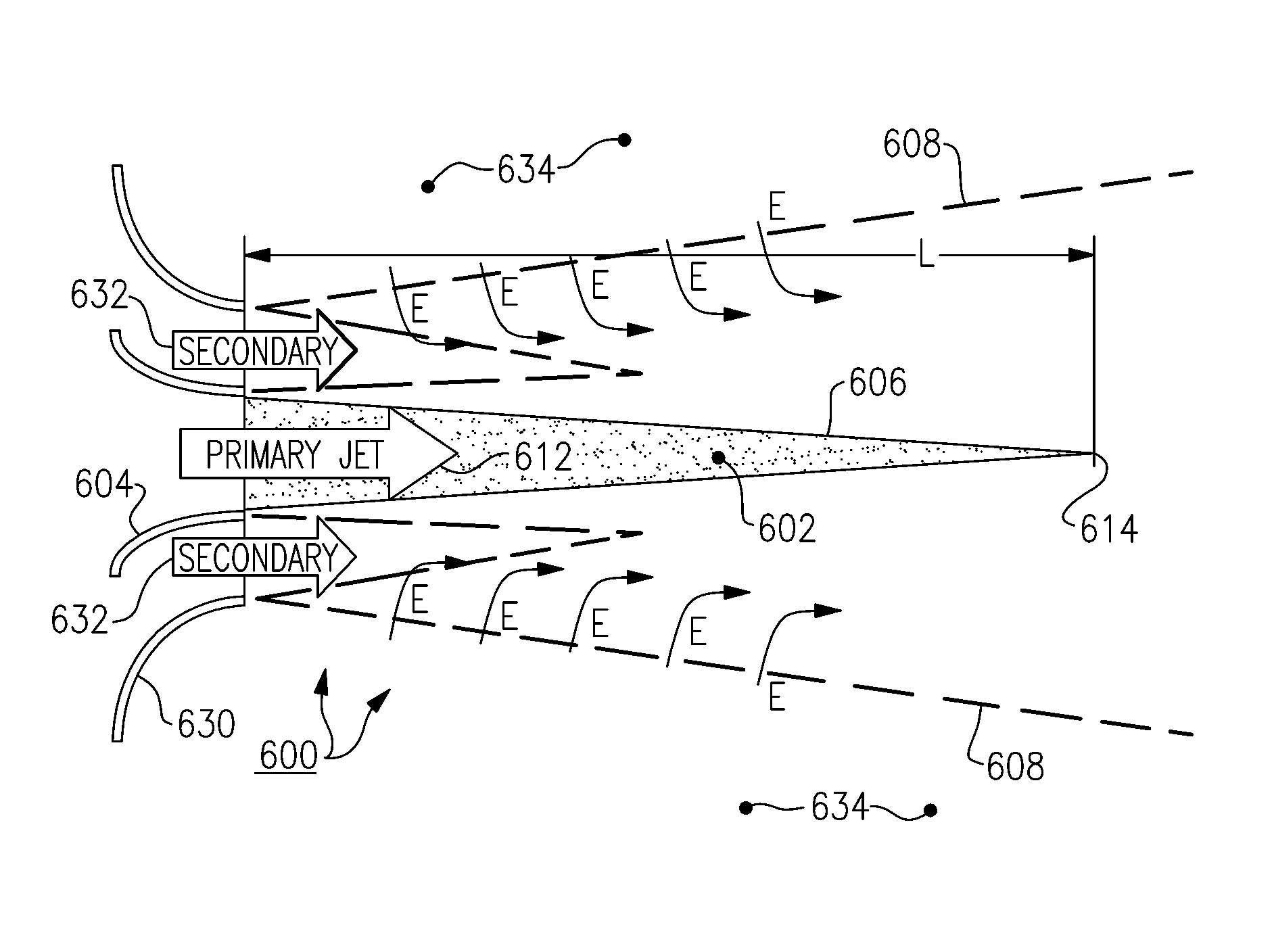

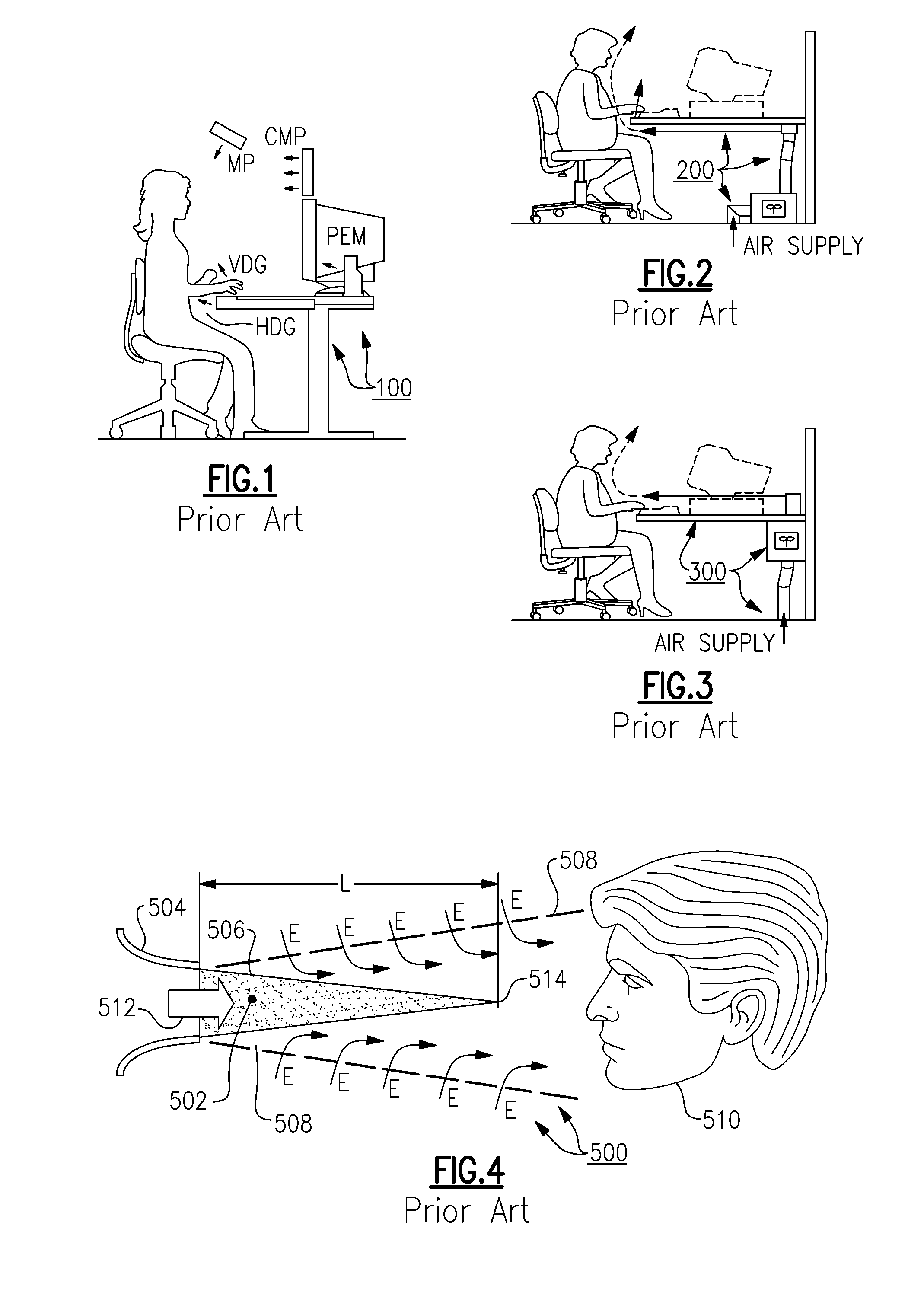

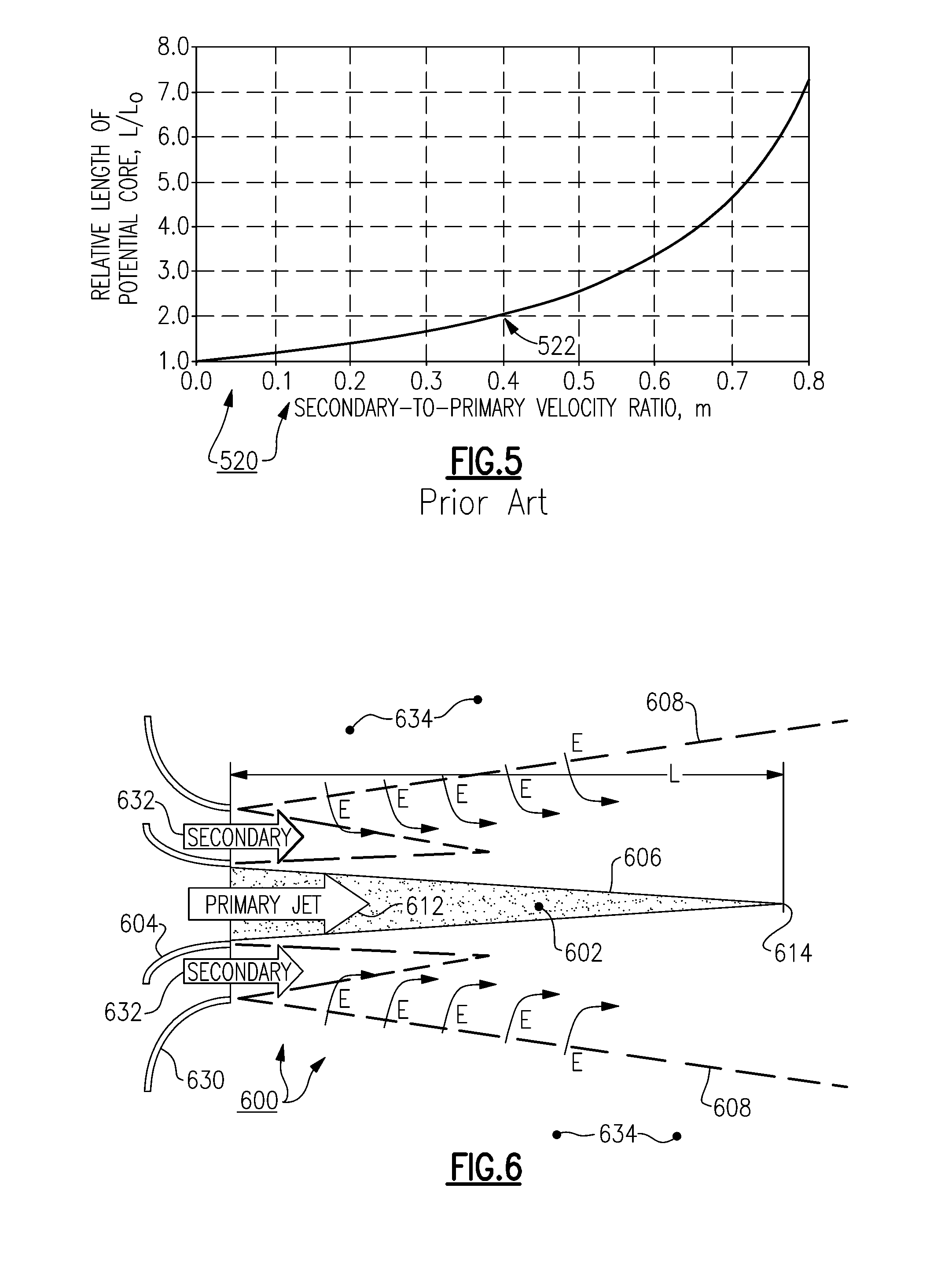

[0046]Before discussing specific embodiments, the theoretical basis of the present invention will first be discussed. An air jet issuing from a nozzle into still or co-flowing air at a different velocity experiences shear at its boundary. For sufficiently high jet Reynolds number, turbulence is produced in the shear layer between the jet and its surrounding medium, and the resulting turbulent eddies greatly enhance the transport of momentum, energy and species in this shear layer. As a result, the potential core of the jet gradually erodes due to the entrainment of low momentum fluid from the surrounding medium into the jet. This turbulent transport also enhances the entrainment of species from the surrounding medium into the jet's mixing zone. It has been recognized that the turbulent momentum diffusivity in such free shear layers is proportional to the width of the shear layer and the difference between the jet centerline velocity and the velocity of the surrounding medium (zero f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com